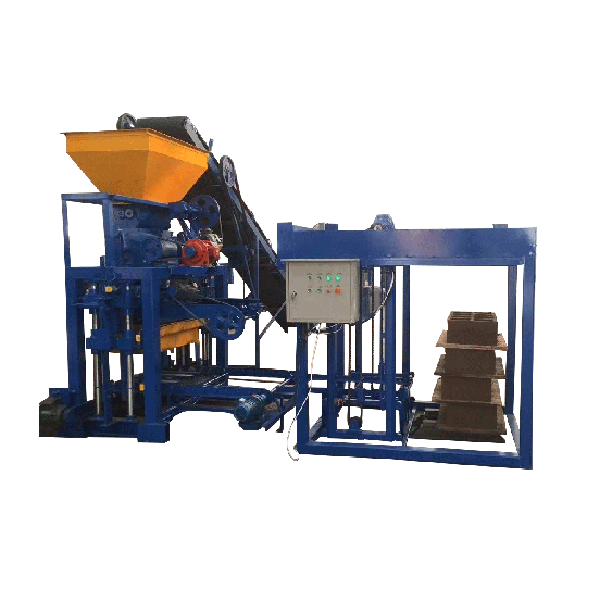

The QT4-35 Manual Brick Making Machine is a robust and adaptable solution designed for small to medium-scale block and brick manufacturing plants. With its simple yet efficient mechanical design, the QT4-35 enables manufacturers, distributors and project contractors to deliver a wide range of concrete masonry products — from hollow blocks and solid bricks to pavers and curbstones.

1. Flexible Mould System – Broad Product Portfolio

One of the key advantages of the QT4-35 is its customizable moulding configuration. By changing the mould sets, operators can handle multiple product lines using the same host machine:

-

Hollow concrete blocks: Lightweight units that offer lower dead-load, improved thermal insulation and opportunity for reinforcement or service channels.

-

Solid bricks / dense blocks: Ideal for load-bearing structures, retaining walls and high-compressive-strength applications.

-

Paver bricks & interlocking units: Surface decorative and functional paving bricks for walkways, patios and driveways — by simply switching to the corresponding mould.

-

Curbstones and speciality shapes: With the correct tooling, the machine manufactures kerb blocks, corner blocks, decorative textured bricks and other custom items.

-

Color and texture variations: While the QT4-35 primarily shapes the product, it supports casting mixes with pigments, stone powder or textured surfaces — enabling product differentiation.

2. Productivity & Quality Control

Despite being manually (or semi-manually) operated, the QT4-35 delivers impressive throughput and consistent output quality — important for any export-oriented business like ours.

-

The machine features a raw-material hopper, which reduces labour cost and ensures smoother feeding of mix materials such as cement, sand, crushed stone or powder.

-

According to manufacturer data: for example with hollow blocks sized 400×200×200 mm, output can reach 2,560-3,290 pieces in an 8-hour shift.

-

For solid brick formats (e.g., 240×50×115 mm) the machine can reach 11,520-14,784 pieces per day under ideal conditions.

-

The design emphasises uniform compaction via vibration or compression, mould stability (e.g., heavy-duty frame, manganese steel moulds) and dimensional accuracy.

3. Raw Materials & Equipment Requirements

For optimal operation of the QT4-35, the following factors are key:

-

Mix design: Use of cement, sand, crushed stones or stone powder as feedstock. Proper aggregate grading and moisture control are vital for strength and surface finish.

-

Workshop layout: A dedicated curing / stacking area, sufficient floor area (manufacturers suggest around 200 m² for one unit) and proper pallet handling system.

-

Labour/operation: Typically 3-5 operators (one for mixer, one for host machine, some for trolley/stacking) for the manual version.

-

Power/ancillaries: Host machine may draw approximately ~18-24 kW depending on configuration; pallet size often ~850×450 mm in some specs.

4. Competitive Advantages for Export & Sales

As you prepare your sales pitch and marketing materials (especially targeting international buyers), here are several competitive angles for the QT4-35 that you can highlight:

-

Versatility: One machine covers multiple product types — hollow block, solid brick, paver, curbstone — reducing need for separate equipment lines.

-

Low capital investment: The manual/semi-manual structure lowers upfront cost while still achieving substantial output — appealing to start-up factories or export markets where cost is critical.

-

Customisation: Mould sets can be tailored to local market sizes, shapes and architectural demands (e.g., regional block dimensions, aesthetic preferences).

-

Durability and service: High-strength mould steel, heavy-duty frame, reliable feed system — argue lower maintenance and long service-life.

-

Scalable: For clients who start small, QT4-35 offers a footprint they can scale later, add curing, stacking, pallet conveyors or upgrade to semi-auto models.

-

After-sales support: Emphasise your company’s export service, spare-parts supply, installation support etc (align with your role at Raytone).

5. Recommended SEO Keywords & Phrases for Your Independent Site

Since you’re focusing on the international market, here are suggested keywords and phrases (you can combine with modifiers like “manual block machine”, “brick making machine”, “hollow block machine”, etc.):

-

“QT4-35 manual brick making machine”

-

“QT4-35 manual block machine export”

-

“QT4-35 concrete block maker hollow solid”

-

“manual block making machine small brick factory”

-

“QT4-35 brick / paver / curbstone mould machine”

-

“manual brick moulding machine for export”

-

“QT4-35 block machine OEM mould customization”

-

“small scale concrete block production machine QT4-35”

These keyword phrases will help search engines and your target clients in foreign markets find your machine offering.

Conclusion

For international buyers, especially in regions developing construction infrastructure or starting small-scale block factories, the QT4-35 manual brick making machine represents a compelling value proposition: versatile production, reasonable investment, and expansion potential.

Contact Us

For more information about the QT4-35 manual brick moulding machine and how it can benefit your construction or manufacturing business, contact Raytone Machinery. Our team of experts is ready to help you find the perfect block-making solution for your specific needs. Reach out to us at hazel@raytonechina.com to discuss your requirements and discover how our high-quality, cost-effective machines can enhance your production capabilities.