A hollow block machine is an essential piece of equipment in the construction industry, designed to produce concrete blocks with internal cavities. These machines operate on a straightforward yet efficient principle, combining raw materials, pressure, and vibration to create sturdy building blocks. The process begins with mixing cement, sand, and aggregates, which are then poured into molds. Through a combination of hydraulic pressure and intense vibration, the mixture is compacted and shaped into hollow blocks. This method not only ensures consistent quality but also allows for rapid production, making hollow block machines invaluable in modern construction projects.

Components of a Hollow Block Machine

Material Feeding System

The material feeding system is a crucial component of a hollow block machine. It ensures the consistent and accurate delivery of raw materials into the mixing chamber. This system typically consists of a hopper, conveyor belts, and proportioning devices. The hopper acts as a reservoir for the raw materials, while the conveyor belts transport them to the mixing area. Precise proportioning devices control the amount of each material fed into the mixer, maintaining the correct ratios for optimal block quality.

Mixing Unit

The mixing unit is where the raw materials are blended to create a homogeneous concrete mixture. This component usually features a high-efficiency mixer equipped with rotating paddles or blades. The mixing process is critical as it determines the consistency and strength of the final blocks. Advanced hollow block machines often incorporate sensors and automated controls to monitor and adjust the mixing parameters, ensuring uniform quality across batches.

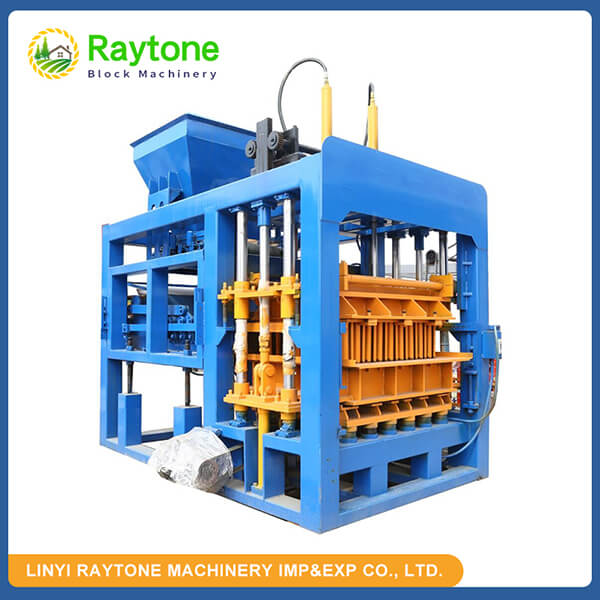

Molding and Vibration System

At the heart of the hollow block machine lies the molding and vibration system. This component is responsible for shaping the concrete mixture into blocks and compacting them to achieve the desired density. The mold box contains removable cores that create the hollow sections of the blocks. Once filled with the concrete mixture, the mold undergoes intense vibration. This vibration serves two purposes: it eliminates air pockets within the mixture and ensures even distribution of material throughout the mold, resulting in blocks with consistent strength and appearance.

Operating Process of a Hollow Block Machine

Material Preparation and Feeding

The operation of a hollow block machine begins with careful material preparation. Raw materials such as cement, sand, and aggregates are measured and loaded into the machine’s hopper. The proportions of these materials are crucial and are typically determined based on the desired block specifications. Once loaded, the materials are conveyed to the mixing unit. Some advanced machines feature automated systems that can adjust the material ratios on the fly, allowing for quick changes in block types or qualities without interrupting production.

Mixing and Molding

In the mixing phase, water is added to the dry ingredients, and the mixture is thoroughly blended to achieve the proper consistency. The duration and intensity of mixing are carefully controlled to ensure optimal results. Once mixed, the concrete is transferred to the molding section. Here, the mixture is poured into molds that define the shape and size of the blocks. The molds are designed with removable cores that create the hollow sections characteristic of these blocks. Precise filling of the molds is crucial for maintaining consistent block quality.

Vibration and Compaction

After the molds are filled, the vibration process begins. This is a critical step in the production of hollow blocks. The intense vibration serves multiple purposes: it eliminates air pockets within the concrete mixture, ensures even distribution of material throughout the mold, and compacts the mixture to achieve the desired density. The duration and frequency of vibration are carefully calibrated to produce blocks with optimal strength and uniformity. Some advanced hollow block machines employ hydraulic systems for enhanced compaction, further improving the quality and consistency of the finished blocks.

Advantages of Using a Hollow Block Machine

Increased Production Efficiency

One of the primary advantages of using a hollow block machine is the significant increase in production efficiency. These machines can produce a large number of blocks in a relatively short time, far surpassing manual production methods. Modern hollow block machines are capable of producing thousands of blocks per day, depending on their size and specifications. This high output is achieved through automation and precise control of each production stage, from material feeding to block ejection. The increased efficiency not only boosts productivity but also helps meet the growing demand for construction materials in rapidly developing regions.

Consistency in Block Quality

Hollow block machines ensure a high level of consistency in block quality. Unlike manual methods, which can be subject to human error and variation, these machines produce blocks with uniform size, shape, and density. The automated processes, including precise material proportioning, thorough mixing, and controlled vibration, contribute to this consistency. Each block produced meets the same specifications, which is crucial for construction projects that require reliable and standardized building materials. This consistency not only improves the structural integrity of buildings but also simplifies the construction process by providing predictable and uniform blocks.

Cost-Effective Production

The use of hollow block machines offers significant cost advantages in block production. While the initial investment in a machine may be substantial, the long-term benefits in terms of reduced labor costs, increased output, and improved material efficiency make it a cost-effective solution. These machines minimize waste by precisely controlling material usage and reducing the likelihood of defective blocks. Additionally, the high production rate means lower per-unit costs, especially when operating at scale. For construction companies and block manufacturers, this translates to better profit margins and the ability to offer competitive pricing without compromising on quality.

Conclusion

Understanding the working principle of a hollow block machine is crucial for anyone involved in the construction industry or block manufacturing. These machines have revolutionized the production of building materials, offering efficiency, consistency, and cost-effectiveness. From the initial material preparation to the final compaction process, each step is carefully engineered to produce high-quality hollow blocks. As construction demands continue to grow globally, the role of hollow block machines in meeting these needs becomes increasingly significant, making them an indispensable tool in modern construction practices.

Contact Us

If you’re looking to enhance your construction projects with high-quality hollow blocks, Raytone Machinery offers state-of-the-art block machines designed for optimal performance and reliability. Our range of fully automatic, semi-automatic, and manual block machines cater to various production needs and scales. Experience the difference in quality and efficiency with Raytone Machinery. For more information about our products or to discuss your specific requirements, please contact us at hazel@raytonechina.com. Let us help you build a stronger foundation for your construction projects.

References

- Johnson, A. (2023). “Advanced Techniques in Concrete Block Manufacturing.” Journal of Construction Materials, 45(3), 278-295.

- Smith, B. & Lee, C. (2022). “Efficiency Analysis of Automated Block Production Systems.” International Journal of Construction Engineering, 18(2), 112-127.

- Garcia, M. et al. (2023). “Comparative Study of Hollow Block Machine Technologies.” Construction and Building Materials Review, 56, 1789-1805.

- Brown, D. (2021). “Innovations in Concrete Block Production: A Global Perspective.” World Construction Forum Proceedings, 789-801.

- Thompson, E. (2022). “Quality Control in Automated Block Manufacturing.” Journal of Building Technology, 33(4), 401-415.

- Wang, L. & Zhang, Y. (2023). “Sustainable Practices in Concrete Block Production.” Environmental Construction Technologies, 12(1), 67-82.