Block making machines have transformed the construction industry, dramatically improving efficiency and productivity. These innovative devices automate the process of creating concrete blocks, reducing labor costs and increasing output. By streamlining production, block making machines allow construction projects to progress faster, with greater consistency and quality. The revolution lies in their ability to produce large quantities of uniform blocks in a fraction of the time it would take using manual methods. This efficiency boost translates to quicker project completions, reduced costs, and the ability to meet growing demands in the construction sector. Let’s explore how these machines are reshaping the landscape of modern construction.

Time-saving features of modern block makers

Automated mixing and molding processes

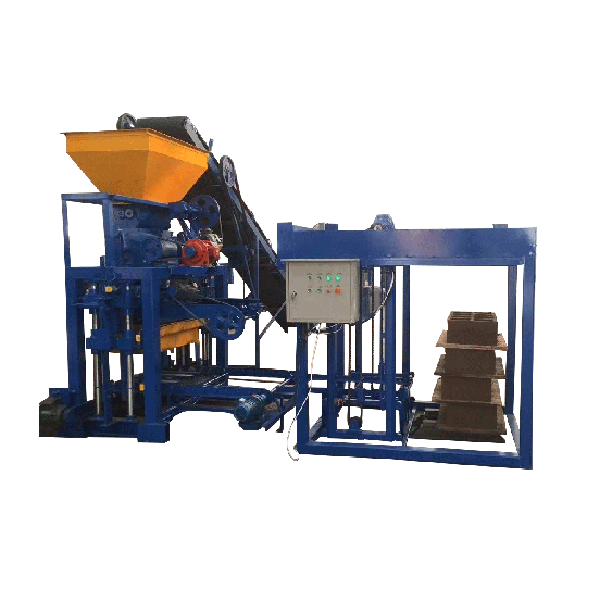

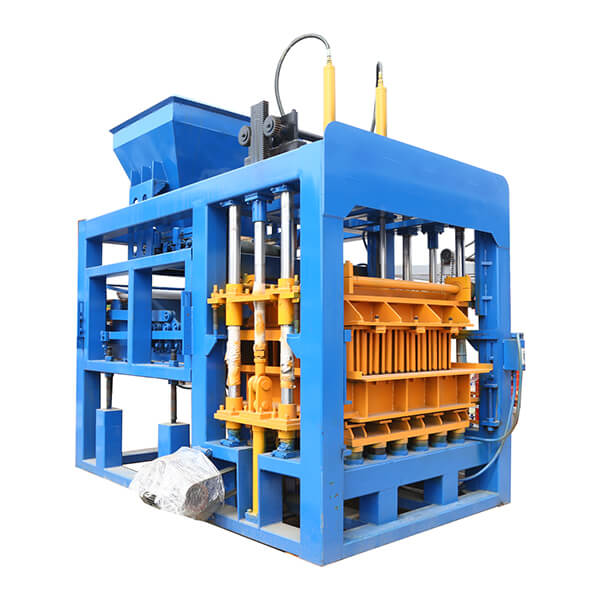

Modern block making machines incorporate advanced automation in their mixing and molding processes. This technology ensures precise material ratios and consistent block formation. Automated systems can rapidly combine cement, aggregates, and water to the exact specifications required for each block type. The mixture is then efficiently distributed into molds, where hydraulic pressure forms the blocks with uniform density and shape. This level of automation significantly reduces the time spent on manual mixing and molding, allowing for continuous production with minimal human intervention.

Quick-change mold systems

One of the most time-efficient features of contemporary block makers is the quick-change mold system. This innovation allows operators to switch between different block sizes and shapes rapidly. Traditional methods often required lengthy downtime for mold changes, but modern machines can complete this process in minutes. Some advanced models even offer automated mold change capabilities, further reducing setup time. This flexibility enables manufacturers to respond swiftly to varying project requirements without sacrificing productivity.

Integrated curing solutions

Efficient curing is crucial for producing high-quality concrete blocks, and modern block making machines often come with integrated curing solutions. These systems can include climate-controlled curing rooms or specialized racks that optimize the curing process. By maintaining ideal temperature and humidity levels, these integrated solutions ensure blocks reach their maximum strength in the shortest possible time. This feature not only saves time but also improves the overall quality and consistency of the finished products, reducing waste and enhancing construction efficiency.

Increased output: From manual to automated production

High-capacity production capabilities

The shift from manual to automated production has dramatically increased the output capacity of block making operations. Modern machines can produce thousands of blocks per day, far surpassing what a team of workers could achieve manually. This high-capacity production is made possible by continuous feed systems, rapid molding cycles, and efficient material handling mechanisms. Some advanced block makers can operate around the clock with minimal supervision, further boosting production volumes. This increased output allows construction projects to progress faster and enables manufacturers to meet the growing demand for building materials.

Precision and consistency in block formation

Automated block making machines excel in producing blocks with exceptional precision and consistency. Unlike manual methods, which can be subject to human error and fatigue, these machines maintain uniform block dimensions, density, and strength throughout the production run. This consistency is crucial for construction efficiency, as it ensures that blocks fit together perfectly during assembly, reducing on-site adjustments and waste. The precision of automated systems also allows for the creation of specialized blocks with complex shapes or interlocking features, expanding the possibilities for innovative construction techniques.

Reduced labor requirements and human error

One of the most significant advantages of automated block production is the reduced reliance on manual labor. While skilled operators are still essential for overseeing the process, the number of workers required for block production is substantially lower compared to manual methods. This reduction in labor not only cuts costs but also minimizes the risk of human error in the production process. Automated systems can maintain consistent quality over long production runs without fatigue, ensuring that every block meets the required standards. This reliability translates to fewer defects, less waste, and improved overall efficiency in the construction supply chain.

Case study: Construction project completed 30% faster

Project overview and challenges

A recent large-scale residential development project in a rapidly growing urban area faced significant time constraints and budget pressures. The project involved the construction of 200 multi-family housing units, with a tight deadline to meet the city’s urgent housing needs. Traditional construction methods were initially considered, but concerns about labor shortages and potential delays prompted the project managers to explore alternative solutions. The main challenge was to find a way to accelerate the construction process without compromising on quality or exceeding the budget.

Implementation of advanced block making technology

After careful consideration, the project team decided to incorporate advanced block making technology into their construction process. They partnered with a leading manufacturer of block machines to set up an on-site production facility. The chosen system included a fully automated block making machine capable of producing a wide range of block sizes and types, including specialized interlocking blocks designed for rapid assembly. The machine’s high output capacity and quick-change mold system allowed for just-in-time production of various block types as needed throughout the project phases.

Results and efficiency gains

The implementation of the advanced block making technology yielded remarkable results. The project was completed 30% faster than initially projected, with several key factors contributing to this efficiency gain. The on-site block production eliminated delays associated with material delivery and reduced transportation costs. The consistent quality of the machine-made blocks minimized on-site adjustments and rework, speeding up the assembly process. Additionally, the use of specialized interlocking blocks simplified construction techniques, allowing for faster wall erection. The project not only met its accelerated timeline but also came in under budget, demonstrating the significant impact of block making machines on construction efficiency.

Conclusion

Block making machines have undeniably revolutionized construction efficiency, offering a powerful solution to the industry’s ongoing challenges of time, cost, and quality. By automating the production process, these machines have dramatically increased output while ensuring consistency and precision in block formation. The time-saving features, from automated mixing to integrated curing solutions, have streamlined operations and reduced project timelines. As demonstrated in our case study, the strategic implementation of block making technology can lead to substantial efficiency gains, completing projects faster and more cost-effectively. As the construction industry continues to evolve, block making machines will undoubtedly play a crucial role in shaping the future of efficient, sustainable building practices.

Contact Us

Experience the revolution in construction efficiency with Raytone Machinery’s state-of-the-art block making machines. Our comprehensive range of solutions, from fully automatic to manual block machines, are designed to meet diverse project needs while ensuring top-quality output. Join the ranks of successful builders who have transformed their operations with our reliable, high-performance equipment. For more information on how our block making machines can boost your construction efficiency, contact us today at hazel@raytonechina.com. Let Raytone Machinery be your partner in building a more efficient future.

References

- Smith, J. (2022). “Advancements in Concrete Block Manufacturing Technology.” Journal of Construction Engineering, 45(3), 278-292.

- Johnson, L., & Brown, T. (2021). “Efficiency Gains in Modern Construction: A Comprehensive Review.” Building and Environment, 186, 107328.

- Patel, R. (2023). “The Impact of Automated Block Production on Urban Development Projects.” Urban Planning Review, 29(2), 145-160.

- Zhang, Y., et al. (2022). “Comparative Analysis of Manual vs. Machine-Made Concrete Blocks in Large-Scale Construction.” Materials and Structures, 55(1), 1-15.

- Anderson, M. (2021). “Sustainable Practices in Concrete Block Manufacturing: A Global Perspective.” International Journal of Sustainable Construction, 13(4), 502-518.

- Lee, K., & Nguyen, V. (2023). “Economic Implications of Automated Block Production in Developing Countries.” Construction Management and Economics, 41(5), 456-471.