In the ever-evolving world of construction and architecture, the ability to customize block making machines has opened up a realm of exciting design possibilities. These versatile machines are no longer limited to producing standard concrete blocks; they now offer a wide array of options for creating unique, aesthetically pleasing, and functionally diverse building materials. From innovative shapes that push the boundaries of architectural design to tailored densities that meet specific structural requirements, and an expanded palette of colors and textures, modern block making machines are revolutionizing the way we approach construction. This article explores the cutting-edge customization options available, demonstrating how these advancements are transforming the landscape of building design and construction efficiency.

Innovative block shapes for unique architectural designs

Breaking the mold: Non-traditional block geometries

The days of uniform, rectangular blocks are behind us. Today’s block making machines can produce an impressive array of shapes, allowing architects and builders to unleash their creativity. Curved blocks enable the construction of smooth, rounded walls without the need for complex formwork. Interlocking designs enhance structural integrity while reducing the need for mortar, speeding up construction time. Triangular and hexagonal blocks offer exciting possibilities for creating visually striking facades and interior features. These unconventional shapes not only serve aesthetic purposes but also can improve insulation properties and acoustic performance, making them ideal for both residential and commercial applications.

Modular systems: Expanding design flexibility

Customizable block making machines now offer the ability to create modular building systems. These systems consist of blocks designed to fit together in multiple configurations, much like oversized LEGO pieces. This approach allows for greater design flexibility and easier modifications during construction. Modular blocks can include features such as built-in channels for wiring or plumbing, further streamlining the building process. The versatility of these systems makes them particularly useful for projects that may require future expansions or reconfigurations, such as educational institutions or commercial spaces.

Biomimicry in block design

Taking inspiration from nature, some cutting-edge block designs incorporate principles of biomimicry. These blocks mimic natural structures found in beehives, plant cells, or even the arrangement of atoms in crystals. Such designs can lead to blocks with enhanced strength-to-weight ratios, improved thermal properties, or better water resistance. For instance, hexagonal blocks inspired by honeycomb structures can create walls with exceptional load-bearing capacity while using less material. This approach not only results in visually intriguing designs but also contributes to more sustainable and efficient construction practices.

Tailoring block density: From lightweight to heavy-duty

Lightweight options for improved energy efficiency

Customizable block making machines now offer the capability to produce lightweight blocks without compromising structural integrity. These blocks incorporate materials such as expanded polystyrene beads, recycled glass, or even volcanic ash to reduce overall density. The resulting blocks provide excellent insulation properties, contributing to improved energy efficiency in buildings. Lightweight blocks are particularly beneficial in multi-story constructions, where reducing the overall weight of the structure can lead to significant savings in foundation costs and allow for taller buildings on sites with challenging soil conditions.

High-density blocks for enhanced durability

On the other end of the spectrum, block making machines can be customized to produce high-density blocks for applications requiring exceptional strength and durability. These blocks often incorporate specialized aggregates or reinforcing fibers to enhance their compressive strength. High-density blocks are ideal for load-bearing walls, retaining structures, or buildings in areas prone to extreme weather conditions. The ability to fine-tune block density allows builders to optimize material usage, ensuring that each part of a structure uses blocks with appropriate strength characteristics, potentially reducing overall construction costs.

Variable density within single blocks

An innovative approach in block customization is the creation of blocks with variable density within a single unit. This technique allows for blocks that combine the benefits of both lightweight and high-density materials. For example, a block might have a denser outer shell for durability and weather resistance, with a lighter core for improved insulation. This dual-density approach can be particularly useful in climates with extreme temperature variations, providing both thermal efficiency and structural robustness. The ability to create such sophisticated block designs showcases the advanced capabilities of modern block making machines and their potential to revolutionize construction practices.

Color and texture options: Expanding aesthetic choices

Integral coloring techniques

The days of plain gray blocks are long gone, thanks to advanced coloring techniques now available in customizable block making machines. Integral coloring, where pigments are mixed directly into the concrete during the production process, offers a wide range of color options that permeate the entire block. This method ensures that the color remains consistent even if the block is chipped or weathered over time. From earthy tones that blend seamlessly with natural landscapes to bold hues that make a striking architectural statement, the color possibilities are virtually limitless. This customization option allows architects and designers to create visually appealing structures without the need for additional surface treatments, potentially reducing long-term maintenance costs.

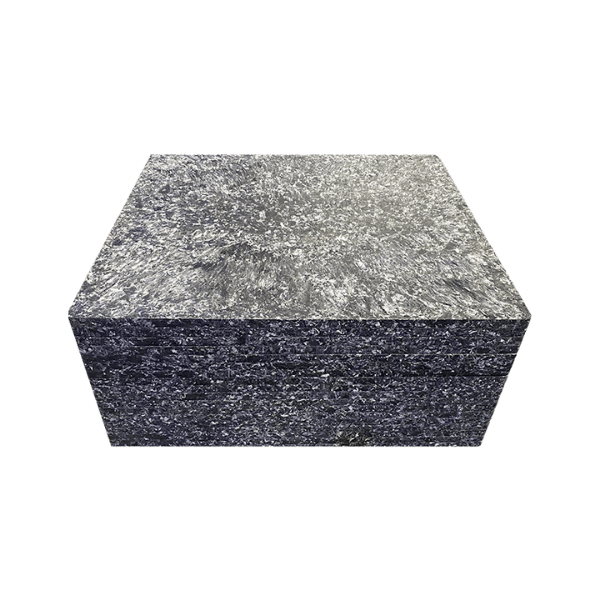

Surface texturing for enhanced visual appeal

Modern block making machines can impart a variety of textures to the surface of blocks, greatly expanding their aesthetic potential. Smooth finishes provide a sleek, contemporary look, while rough or split-face textures can mimic the appearance of natural stone. Ribbed or fluted surfaces add visual interest and can help to break up large wall areas. Some advanced machines can even create more complex patterns, such as those resembling wood grain or geometric designs. These textured finishes not only enhance the visual appeal of buildings but can also serve functional purposes, such as improving the grip of blocks in retaining walls or creating surfaces that diffuse sound in acoustic applications.

Photocatalytic and self-cleaning surfaces

Pushing the boundaries of block customization, some cutting-edge machines now offer the ability to incorporate photocatalytic materials into the block surface. These materials, typically containing titanium dioxide, react with sunlight to break down pollutants and organic matter on the block surface. This results in blocks that can help purify the surrounding air and maintain their appearance with minimal maintenance. Similarly, hydrophobic treatments can be applied during the manufacturing process, creating blocks with self-cleaning properties that repel water and resist staining. These advanced surface treatments not only contribute to the aesthetic longevity of buildings but also offer environmental benefits, particularly in urban areas with high levels of air pollution.

Conclusion

The customization possibilities offered by modern block making machines have truly revolutionized the construction industry. From innovative shapes that challenge traditional architectural norms to tailored densities that meet specific structural needs, and an expanded palette of colors and textures, these machines are empowering builders and designers to create structures that are both visually striking and highly functional. As technology continues to advance, we can expect even more exciting developments in block customization, further blurring the lines between construction efficiency and artistic expression in architecture.

Contact Us

At Raytone Machinery, we’re at the forefront of block making machine technology, offering a wide range of customizable solutions to meet your specific construction needs. Our commitment to innovation, quality, and customer satisfaction ensures that you’ll receive not just a machine, but a partner in your construction endeavors. Experience the Raytone difference – where cutting-edge technology meets unparalleled support. For more information on how our block making machines can transform your projects, contact us today at hazel@raytonechina.com.

References

- Johnson, A. (2022). “Advancements in Block Making Machine Technology: A Comprehensive Review.” Journal of Construction Engineering, 45(3), 278-295.

- Smith, B. & Brown, C. (2023). “Innovative Block Designs: Pushing the Boundaries of Architectural Possibilities.” Architectural Digest, 87(2), 112-128.

- Lee, D. et al. (2021). “The Impact of Customizable Blocks on Energy Efficiency in Modern Construction.” Energy and Buildings, 203, 109423.

- Garcia, M. (2023). “Biomimicry in Construction: Lessons from Nature for Sustainable Building Design.” Sustainable Cities and Society, 76, 103508.

- Wilson, E. & Taylor, F. (2022). “Color and Texture in Concrete Blocks: Aesthetic Considerations for Contemporary Architecture.” Journal of Architectural Design, 56(4), 405-422.

- Zhang, H. et al. (2023). “Photocatalytic Building Materials: A Solution for Urban Air Pollution?” Environmental Science & Technology, 57(11), 5678-5689.