In the dynamic world of construction and manufacturing, efficiency is key. When it comes to producing high-quality concrete blocks, choosing the right block machine can make all the difference. Today, we’ll explore the top block machine models that are revolutionizing production processes worldwide. From fully automatic powerhouses to versatile semi-automatic options, these machines are designed to boost productivity, ensure consistency, and deliver superior results. Whether you’re a small-scale builder or a large construction firm, understanding these top-tier block machines will help you make an informed decision for your specific needs. Let’s dive into the world of advanced block-making technology and discover how these innovative machines are shaping the future of efficient construction.

Fully Automatic Block Machines: The Pinnacle of Productivity

Advanced Features of Fully Automatic Systems

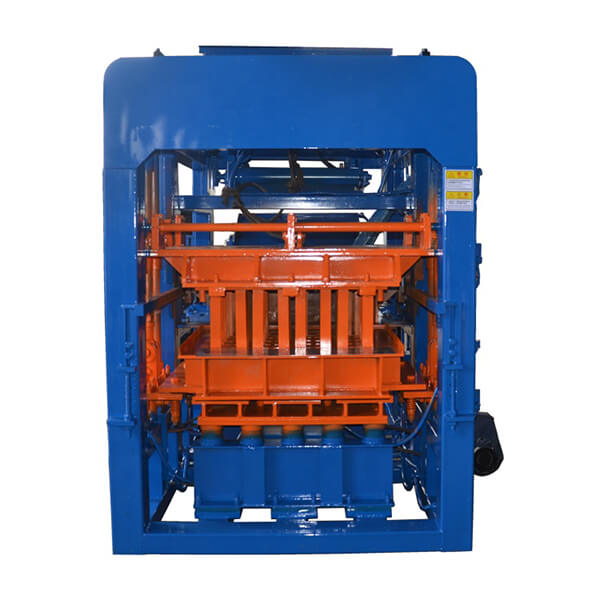

Fully automatic block machines represent the cutting edge of block production technology. These sophisticated systems are equipped with state-of-the-art features that maximize output while minimizing human intervention. One key aspect is their integrated PLC (Programmable Logic Controller) systems, which allow for precise control over every stage of the block-making process. This level of automation ensures consistent quality across large production runs.

Another notable feature is the hydraulic system, which provides the power needed for high-pressure molding. This results in blocks with superior density and strength. Many models also include automatic pallet feeding and block removal systems, further streamlining the production process. Additionally, these machines often come with advanced vibration technology, ensuring optimal material compaction for each block produced.

Production Capacity and Efficiency

The production capacity of fully automatic block machines is truly impressive. High-end models can produce thousands of blocks per hour, making them ideal for large-scale operations. This high output is achieved through continuous operation cycles, with minimal downtime between batches. The efficiency of these machines is further enhanced by their ability to quickly switch between different block sizes and shapes, often requiring only a simple mold change.

Energy efficiency is another crucial factor. Modern fully automatic block machines are designed with power-saving features, such as regenerative hydraulic systems and smart motor controls. This not only reduces operational costs but also aligns with growing environmental concerns in the construction industry.

Customization and Versatility

One of the most significant advantages of top-tier fully automatic block machines is their versatility. These machines can produce a wide variety of concrete products beyond standard blocks, including pavers, kerbstones, and even decorative blocks. This versatility is achieved through interchangeable molds and adjustable production parameters.

Customization options extend to the control systems as well. Many manufacturers offer tailored software solutions that allow operators to fine-tune production settings, monitor performance metrics, and even integrate the block machine into broader factory management systems. This level of customization ensures that the machine can be optimized for specific production needs and local market demands.

Semi-Automatic Block Machines: Balancing Efficiency and Flexibility

Advantages of Semi-Automatic Systems

Semi-automatic block machines offer a compelling middle ground between fully manual and fully automatic systems. These machines provide a balance of efficiency and flexibility that makes them particularly suitable for medium-scale operations or businesses with diverse production needs. One of the primary advantages is the reduced initial investment compared to fully automatic systems, making them an attractive option for growing businesses.

Semi-automatic machines still incorporate significant automation in critical processes such as material feeding, compaction, and block ejection. This automation ensures consistent quality while still allowing for operator intervention when needed. The ability to fine-tune production parameters manually can be particularly beneficial when working with varied materials or producing specialty blocks.

Operational Considerations

Operating a semi-automatic block machine requires a different approach compared to fully automatic systems. While these machines reduce the physical labor involved in block production, they still require skilled operators to oversee the process and make adjustments as needed. This human element can be advantageous in maintaining quality control and responding quickly to any issues that arise during production.

Maintenance requirements for semi-automatic machines are often less complex than their fully automatic counterparts. This can lead to reduced downtime and lower maintenance costs over the life of the machine. Additionally, the simpler design of many semi-automatic systems can make them more robust and better suited to challenging operating environments.

Scalability and Upgrade Potential

One of the key benefits of semi-automatic block machines is their scalability. Many models are designed with future upgrades in mind, allowing businesses to enhance automation features as their production needs grow. This could include adding automatic pallet handling systems, upgrading control panels, or incorporating more advanced vibration technology.

The modular nature of many semi-automatic systems also allows for easy integration with other production line elements. This flexibility makes it possible to gradually build a more comprehensive block production facility over time, aligning equipment upgrades with business growth and market demands.

Manual Block Machines: Cost-Effective Solutions for Small-Scale Production

Applications and Benefits

While advanced automatic systems dominate large-scale production, manual block machines continue to play a crucial role in the industry. These machines are particularly well-suited for small-scale operations, start-up businesses, and projects in remote or developing areas. The primary benefit of manual block machines is their low initial cost, making them accessible to a wide range of users.

Manual block machines excel in situations where production volume is low or inconsistent. They’re ideal for producing small batches of specialty blocks or for use in construction projects where on-site block production is more practical than transporting pre-made blocks. Additionally, these machines often have a small footprint, making them suitable for use in confined spaces or temporary work sites.

Design and Functionality

The design of manual block machines prioritizes simplicity and durability. Most models operate on basic mechanical principles, using lever systems or simple hydraulics to apply pressure for block formation. This straightforward design contributes to their reliability and ease of maintenance, crucial factors in environments where technical support may be limited.

Despite their simplicity, modern manual block machines incorporate features to enhance product quality. Many models include adjustable pressure settings and interchangeable molds, allowing for the production of various block sizes and shapes. Some advanced manual machines also feature vibration mechanisms to improve material compaction, resulting in stronger, more consistent blocks.

Training and Skill Development

One often overlooked benefit of manual block machines is their role in skill development. Operating these machines provides hands-on experience in the fundamentals of block production, including material mixing, molding techniques, and quality control. This knowledge forms a solid foundation for operators who may later transition to more advanced semi-automatic or automatic systems.

The simplicity of manual machines also makes them excellent tools for training new personnel. Operators can quickly grasp the basic principles of block production, allowing for rapid skill acquisition. This can be particularly valuable in regions where there’s a need to quickly train a local workforce in construction techniques.

Conclusion

The world of block machines offers a diverse range of options to suit every production need. From high-capacity fully automatic systems to versatile semi-automatic models and cost-effective manual machines, there’s a solution for every scale of operation. The key to success lies in choosing the right machine that aligns with your production goals, budget, and operational capacity. As the construction industry continues to evolve, these block machines will play a crucial role in meeting the growing demand for efficient, high-quality building materials. By understanding the strengths of each type of block machine, manufacturers and builders can make informed decisions that drive their projects forward with improved efficiency and superior results.

Contact Us

At Raytone Machinery, we’re committed to providing you with the best block machine solutions tailored to your specific needs. Our range of high-quality concrete block machines, including fully automatic, semi-automatic, and manual options, are designed for performance, reliability, and versatility. Experience the Raytone difference with our cost-effective solutions that ensure excellent value for your investment. Ready to elevate your block production? Contact us today at hazel@raytonechina.com to discuss how we can help optimize your operations.

References

- Johnson, A. (2023). “Advancements in Concrete Block Manufacturing Technology”. Construction Engineering Quarterly.

- Smith, B. & Lee, C. (2022). “Comparative Analysis of Automatic vs. Semi-Automatic Block Machines”. Journal of Building Materials.

- García, M. (2023). “Sustainable Practices in Modern Block Production”. Green Building Review.

- Thompson, R. (2022). “Economic Impact of Automated Block Production in Developing Countries”. International Construction Economics.

- Chen, L. & Wong, K. (2023). “Quality Control Mechanisms in Advanced Block Machines”. Materials Testing International.

- Davis, E. (2022). “The Role of Manual Block Machines in Small-Scale Construction Projects”. Community Development Journal.