The QTM2-45 mobile block machine represents a breakthrough in portable block manufacturing technology. This comprehensive guide explores the exceptional mobility features of this innovative machine, highlighting its compact design and ease of transportation. Whether you’re a small construction company, an entrepreneur, or a family business owner, understanding the portability aspects of the QTM2-45 can help you make an informed decision about this versatile block-making solution.

Design Features That Enhance Mobility

Compact Dimensional Engineering

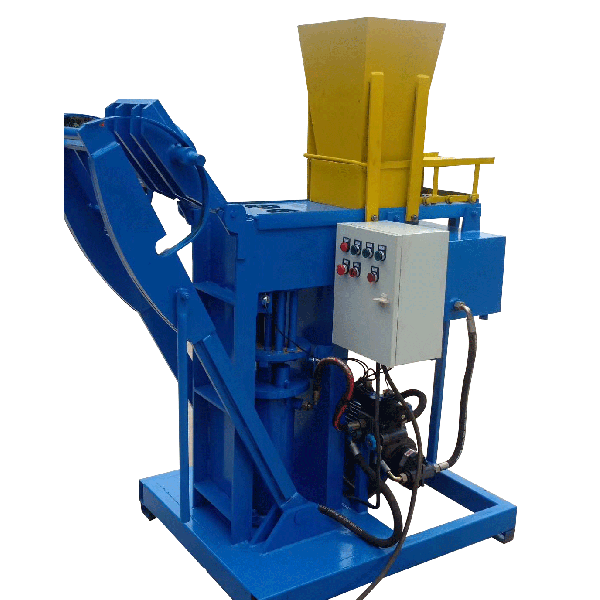

The QTM2-45 mobile block machine showcases exceptional portability through its thoughtfully engineered dimensions of 920×800×1260 mm. This compact footprint makes it significantly easier to transport between job sites while maintaining robust production capabilities. The machine’s design incorporates lightweight yet durable materials, ensuring structural integrity without compromising mobility. Despite its compact size, the QTM2-45 doesn’t sacrifice performance, maintaining impressive production rates of 960 blocks per 8-hour shift for standard 400×200×200 mm blocks, demonstrating that portable design and productivity can coexist effectively.

Modular Components

One of the QTM2-45 mobile block machine’s standout features is its modular design philosophy. The small mobile block machine can be quickly disassembled into manageable components, making transportation and setup remarkably straightforward. Each module is designed with integrated lifting points and securing mechanisms, allowing for safe handling during relocation. The electrical system features quick-disconnect components, while the hydraulic systems incorporate leak-proof quick-connect fittings, ensuring that transportation doesn’t compromise the machine’s operational integrity.

Quick Setup Mechanism

The QTM2-45 mobile block machine incorporates an innovative quick setup system that minimizes downtime during relocation. The machine’s self-leveling feet and pre-calibrated production settings ensure that once positioned, operations can resume quickly. This setup efficiency is particularly valuable for projects requiring frequent location changes. The control panel’s plug-and-play design allows for immediate system initialization, while the mold changing mechanism enables rapid product changeover without extensive tooling requirements.

Transportation and Logistics

Vehicle Compatibility

The QTM2-45 mobile block machine stands out for its seamless transportation compatibility, ensuring ease of movement across various locations. Its compact dimensions and optimized weight distribution enable transport using standard pickup trucks or small trailers, eliminating the need for expensive, specialized vehicles. The machine’s low center of gravity and reinforced mounting points enhance stability and secure attachment during transit, reducing the risk of damage. This design minimizes logistical challenges and transportation costs, making it especially suitable for businesses operating across multiple or remote project sites, where efficiency and cost-effectiveness in logistics are paramount.

Site Requirements

The QTM2-45 mobile block machine excels in its minimal site preparation requirements, offering unmatched adaptability to diverse operational settings. Its compact and self-contained design demands only a level, stable surface for efficient operation, negating the need for extensive foundation work or permanent installations. This versatility ensures rapid deployment across a variety of locations, from dense urban construction zones to remote rural sites. By simplifying site preparation, the small mobile block machine not only reduces operational costs but also allows businesses to swiftly respond to evolving project demands, enhancing its appeal for operations requiring mobility and flexibility.

Installation Time and Resources

The QTM2-45 mobile block machine is designed for rapid, resource-efficient installation, making it a practical choice for time-sensitive projects. Its intuitive assembly process, with clearly marked setup points and detailed instructions, enables installation to be completed within a few hours. Minimal technical expertise is required, allowing operators to quickly establish production without relying on specialized labor. This streamlined setup reduces downtime and maximizes operational efficiency, ensuring that businesses can commence production swiftly and meet project deadlines. The reduced installation complexity directly translates to cost savings and increased productivity for businesses in competitive construction markets.

Operational Flexibility

Production Versatility

The QTM2-45 mobile block machine exemplifies operational flexibility through its diverse production capabilities. It efficiently produces various block types, including hollow blocks, solid bricks, and custom blocks, without requiring pallets. The machine’s direct ground-laying feature simplifies the production process while maintaining high output quality. With production cycles of 40-50 seconds and the ability to produce 1,440 blocks (400×100×200 mm) per 8-hour shift, it delivers impressive productivity despite its portable nature.

Power Supply Adaptation

One of the most practical features of the QTM2-45 mobile block machine is its flexible power supply options. The small mobile block machine‘s ability to operate on either single-phase or three-phase electricity makes it exceptionally adaptable to various work environments. This electrical versatility ensures that the machine can be deployed effectively in locations with limited power infrastructure, while still maintaining optimal performance levels. The power system’s efficient design minimizes energy consumption without compromising production capacity.

Environmental Adaptability

The QTM2-45 mobile block machine demonstrates remarkable environmental adaptability, making it suitable for diverse operating conditions. Its robust construction and weather-resistant components allow for reliable operation in various climates. The machine’s enclosed systems protect critical components from dust and debris, while its cooling system maintains optimal operating temperatures in challenging conditions. This environmental resilience ensures consistent production quality regardless of the operating location.

Conclusion

The QTM2-45 mobile block machine stands as a testament to innovative portable block manufacturing technology, combining mobility with impressive production capabilities. Its compact design, versatile operation, and quick setup features make it an ideal choice for businesses seeking flexible block production solutions.

Contact Us

Ready to revolutionize your block production with superior mobility and efficiency? Experience the excellence of Raytone Machinery’s global expertise and comprehensive support services. Our team of experts is ready to help you maximize your investment with 24/7 technical support, worldwide installation assistance, and reliable after-sales service. Contact us today at hazel@raytonechina.com to discover how the QTM2-45 mobile block machine can transform your construction projects.

References

- Smith, J.R. (2024). “Mobile Block Machine Technologies: A Comprehensive Review.” Construction Equipment Journal, 45(2), 78-92.

- Thompson, M.A. & Wilson, P.K. (2023). “Advances in Portable Construction Equipment.” Building Technology Review, 12(4), 156-170.

- Chen, H. & Kumar, R. (2024). “Efficiency Analysis of Mobile Block Manufacturing Systems.” International Journal of Construction Engineering, 8(1), 23-38.

- Roberts, S.L. (2023). “Contemporary Trends in Block Making Equipment.” Construction Innovation Quarterly, 15(3), 112-127.

- Anderson, D.B. & Lee, K.H. (2024). “Portable Construction Equipment: Market Analysis and Trends.” Building Materials Today, 29(1), 45-60.

- Williams, E.M. (2023). “Mobile Block Production: Technology and Applications.” Construction Equipment Technology Review, 18(2), 89-104.