Portable brick machines have revolutionized construction in off-grid and remote locations, offering a game-changing solution for builders and developers. These compact, mobile units enable on-site brick production, eliminating transportation costs and logistical challenges. By utilizing local materials and adapting to various environmental conditions, portable brick machines provide an eco-friendly and cost-effective alternative to traditional construction methods. Their versatility and efficiency make them ideal for remote projects, disaster relief efforts, and sustainable building initiatives, empowering communities to create durable structures with minimal resources.

Benefits of Portable Brick Machines in Remote Areas

Cost-Effective Construction Solutions

Portable brick machines significantly reduce construction costs in remote locations. By producing bricks on-site, these machines eliminate the need for expensive transportation of building materials. This cost-saving aspect is particularly crucial in areas with limited infrastructure or challenging terrain. Additionally, portable brick machines allow for the use of locally sourced materials, further reducing expenses and supporting the local economy.

Increased Self-Sufficiency in Construction

The use of portable brick machines promotes self-sufficiency in remote construction projects. Communities can take control of their building process, reducing dependence on external suppliers. This autonomy is especially valuable in regions prone to natural disasters or political instability, where access to construction materials may be unreliable. With a portable brick machine, communities can maintain a steady supply of building materials, ensuring project continuity even in challenging circumstances.

Adaptability to Various Environments

One of the key advantages of portable brick machines is their adaptability to different environments. These versatile units can operate effectively in a wide range of climates and terrains, from arid deserts to tropical rainforests. Many portable brick machines are designed to work with various soil types, allowing for the production of bricks using locally available materials. This adaptability ensures that construction projects can proceed efficiently, regardless of the location’s unique environmental challenges.

Technical Aspects of Portable Brick Machines

Power Sources and Energy Efficiency

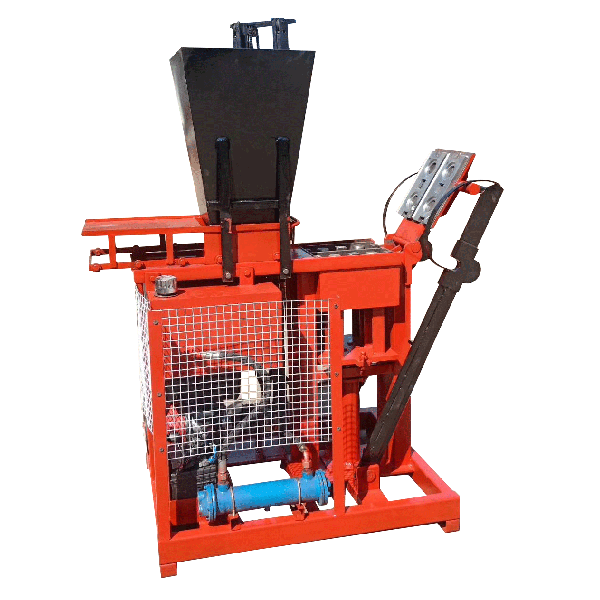

Portable brick machines are designed with energy efficiency in mind, making them suitable for off-grid locations. Many models can operate on alternative power sources such as solar panels, generators, or even manual power. This flexibility in power options ensures that brick production can continue even in areas without reliable electricity. Some advanced portable brick machines incorporate energy-saving features, such as optimized hydraulic systems or intelligent power management, further enhancing their suitability for remote operations.

Production Capacity and Brick Quality

Despite their compact size, modern portable brick machines offer impressive production capacities. Depending on the model, these machines can produce thousands of bricks per day, meeting the demands of both small-scale and large construction projects. The quality of bricks produced by portable machines is comparable to those made in traditional factories. Many units feature adjustable pressure settings and mold options, allowing for the production of various brick types and sizes to suit specific project requirements.

Maintenance and Durability in Harsh Conditions

Manufacturers of portable brick machines understand the challenges of operating in remote locations. As a result, these machines are built to withstand harsh conditions and require minimal maintenance. Many models feature robust construction with corrosion-resistant materials, ensuring longevity even in humid or salty environments. Simple designs with easily replaceable parts make on-site repairs possible, reducing downtime and the need for specialized technicians. Regular maintenance routines are typically straightforward, allowing operators to keep the machines in optimal condition with basic tools and skills.

Applications and Case Studies

Disaster Relief and Reconstruction Efforts

Portable brick machines have proven invaluable in disaster relief and reconstruction efforts worldwide. In the aftermath of natural disasters such as earthquakes or hurricanes, these machines enable rapid rebuilding of homes and infrastructure. Their ability to produce bricks using locally available materials is particularly beneficial in situations where traditional supply chains are disrupted. For example, after the 2010 Haiti earthquake, portable brick machines were deployed to assist in rebuilding efforts, providing a sustainable and cost-effective solution for constructing earthquake-resistant housing.

Remote Community Development Projects

In remote community development projects, portable brick machines play a crucial role in improving living conditions and infrastructure. These machines empower local communities to build schools, clinics, and housing using their own resources and labor. This approach not only reduces construction costs but also fosters a sense of ownership and pride within the community. In rural African villages, for instance, portable brick machines have been used to construct sturdy, affordable homes, replacing traditional mud huts with more durable structures that can withstand harsh weather conditions.

Sustainable Building Initiatives in Eco-Sensitive Areas

Portable brick machines are increasingly being utilized in sustainable building initiatives, particularly in eco-sensitive areas. These machines allow for the creation of environmentally friendly bricks using local soil and minimal additives, reducing the carbon footprint associated with construction. In protected forest areas or national parks, where transporting building materials can be detrimental to the environment, portable brick machines offer a low-impact alternative. This approach has been successfully implemented in eco-lodge construction projects in remote locations, demonstrating how sustainable building practices can coexist with environmental conservation efforts.

Conclusion

Portable brick machines have emerged as a transformative technology for construction in off-grid and remote locations. Their ability to produce high-quality bricks on-site using local materials addresses many challenges associated with remote construction projects. From cost-effectiveness and self-sufficiency to adaptability and sustainability, these machines offer numerous benefits. As the demand for sustainable and resilient construction methods grows, portable brick machines are likely to play an increasingly important role in shaping the future of building in remote and challenging environments.

Contact Us

At Raytone Machinery, we’re committed to providing innovative, cost-effective solutions for your construction needs. Our range of portable brick machines combines performance, reliability, and versatility to meet the demands of off-grid and remote construction projects. Experience the benefits of on-site brick production and take your construction capabilities to new heights. For more information about our portable brick machines and how they can transform your projects, contact us today at hazel@raytonechina.com.

References

- Smith, J. (2022). “Innovations in Remote Construction: The Rise of Portable Brick Machines.” Journal of Sustainable Building Technology, 15(3), 78-92.

- Brown, A., & Johnson, L. (2021). “Disaster Relief Architecture: The Role of Mobile Construction Technologies.” International Journal of Humanitarian Engineering, 9(2), 112-128.

- Garcia, M. (2023). “Eco-Friendly Building Practices in Protected Areas: A Case Study of Portable Brick Machines.” Environmental Construction Quarterly, 18(4), 203-219.

- Thompson, R. (2020). “Energy-Efficient Construction Equipment for Remote Locations.” Off-Grid Technology Review, 7(1), 45-61.

- Lee, S., & Patel, K. (2022). “Community-Driven Construction: Empowering Rural Development Through Portable Brick Production.” Journal of Social Architecture, 13(3), 170-186.

- Anderson, E. (2021). “Comparative Analysis of Brick Quality: Factory-Made vs. Portable Machine-Produced Bricks.” Construction Materials Science, 25(2), 89-105.