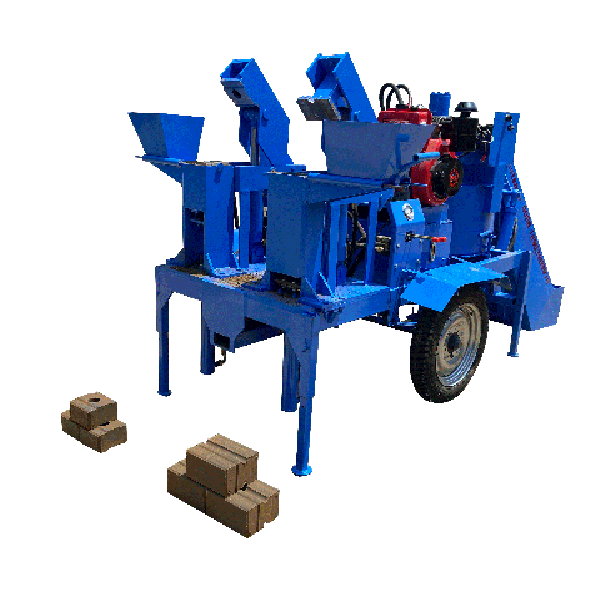

Mobile diesel block machines have revolutionized remote construction projects, offering unparalleled flexibility and efficiency in areas where traditional power sources are scarce. These versatile machines combine the robust power of diesel engines with the portability needed for remote locations, enabling contractors to produce high-quality concrete blocks on-site. By eliminating the need for long-distance transportation of building materials, mobile diesel block machines significantly reduce project costs and timelines. Their ability to operate independently of electrical grids makes them ideal for rural development, disaster relief efforts, and infrastructure projects in underdeveloped regions. As construction demands continue to evolve, these machines stand at the forefront of innovation, bridging the gap between modern building techniques and challenging environments.

Advantages of Mobile Diesel Block Machines in Remote Settings

Portability and Versatility

Mobile diesel block machines excel in their ability to be transported easily to remote construction sites. Their compact design and sturdy build allow for seamless relocation, even in challenging terrains. This portability is crucial for projects in areas with limited infrastructure, where traditional construction methods might be impractical or cost-prohibitive. The versatility of these machines extends to their production capabilities, with many models offering adjustable molds to create various block sizes and shapes. This flexibility enables contractors to adapt to different project requirements without the need for multiple specialized machines, streamlining operations and reducing equipment costs.

Fuel Efficiency and Power

The diesel engines powering these block machines are renowned for their fuel efficiency and robust performance. Modern diesel technology has significantly improved fuel consumption rates, allowing for extended operation periods between refueling. This efficiency is particularly valuable in remote locations where fuel supplies may be limited or expensive to transport. The power output of diesel engines ensures consistent production rates, even under demanding conditions. Many advanced models incorporate electronic fuel injection systems and turbochargers, further enhancing performance and reducing emissions. This combination of efficiency and power makes mobile diesel block machines ideal for sustaining long-term construction projects in isolated areas.

Reduced Dependence on External Power Sources

One of the most significant advantages of mobile diesel block machines is their independence from external power grids. In remote locations, reliable electricity supply can be a major challenge, often leading to project delays and increased costs. Diesel-powered machines eliminate this dependency, allowing construction to proceed uninterrupted. This self-sufficiency not only ensures consistent production but also provides greater flexibility in site selection. Projects can be undertaken in areas previously considered unsuitable due to lack of power infrastructure. Additionally, the ability to operate off-grid reduces the environmental impact associated with extending power lines to remote locations, aligning with sustainable construction practices.

Key Features of High-Performance Mobile Diesel Block Machines

Advanced Hydraulic Systems

High-performance mobile diesel block machines are equipped with sophisticated hydraulic systems that optimize the block-making process. These systems ensure precise control over mold compression, resulting in blocks of consistent quality and strength. Advanced hydraulic circuits allow for rapid cycle times, significantly boosting production rates. Many modern machines feature proportional valves and load-sensing pumps, which adjust hydraulic pressure and flow based on the specific requirements of each production cycle. This intelligent hydraulic management not only improves efficiency but also reduces wear on components, extending the machine’s operational life and minimizing maintenance downtime.

Automated Control Systems

Cutting-edge mobile diesel block machines incorporate automated control systems that streamline operations and enhance productivity. These systems often feature touchscreen interfaces that allow operators to easily adjust production parameters, monitor performance metrics, and troubleshoot issues in real-time. Programmable logic controllers (PLCs) enable the automation of complex production sequences, ensuring consistency across batches and reducing the potential for human error. Some advanced models even offer remote monitoring capabilities, allowing project managers to oversee production from off-site locations. This level of automation not only increases efficiency but also improves safety by minimizing the need for manual intervention in the production process.

Durable Construction and Weather Resistance

Given the challenging environments in which mobile diesel block machines often operate, durability is a critical feature. Leading manufacturers design these machines with robust frames, often using high-strength steel alloys to withstand the rigors of constant operation and frequent relocation. Protective coatings and sealed electrical components enhance resistance to dust, moisture, and extreme temperatures, ensuring reliable performance in diverse climates. Many models feature reinforced hoppers and conveyor systems to handle abrasive materials without premature wear. This emphasis on durability translates to increased uptime, lower maintenance costs, and a longer overall lifespan for the equipment, making mobile diesel block machines a sound investment for remote construction projects.

Maximizing Efficiency with Mobile Diesel Block Machines

Optimizing Material Mix and Production Cycles

Achieving maximum efficiency with mobile diesel block machines begins with optimizing the material mix and production cycles. The ideal mixture of aggregates, cement, and water varies depending on the desired block properties and local raw materials. Experienced operators fine-tune these ratios through careful testing and adjustment, ensuring the production of high-quality blocks while minimizing material waste. Cycle time optimization involves balancing factors such as mold fill time, vibration duration, and curing period. Advanced machines often offer preset programs for different block types, allowing for quick adjustments between production runs. By meticulously refining these aspects, contractors can significantly increase daily output without compromising on block quality.

Implementing Effective Maintenance Schedules

Regular maintenance is crucial for maintaining the efficiency and longevity of mobile diesel block machines. A well-structured maintenance schedule should include daily inspections of critical components such as hydraulic systems, diesel engines, and mold assemblies. Periodic servicing, including oil changes, filter replacements, and belt adjustments, prevents unexpected breakdowns and ensures optimal performance. Many modern machines are equipped with condition monitoring systems that alert operators to potential issues before they escalate into major problems. By adhering to manufacturer-recommended maintenance protocols and addressing minor issues promptly, operators can minimize downtime and maintain consistent production rates, even in challenging remote environments.

Training and Skill Development for Operators

The efficiency of mobile diesel block machines is heavily influenced by the skill level of their operators. Comprehensive training programs are essential for maximizing the potential of these sophisticated machines. Operators should be thoroughly versed in all aspects of machine operation, from startup procedures to troubleshooting common issues. Advanced training might cover topics such as optimizing mix designs for different block types, interpreting machine diagnostics, and performing basic maintenance tasks. Many manufacturers offer on-site training sessions or virtual learning platforms to ensure operators are continuously updating their skills. By investing in operator education, construction companies can significantly enhance productivity, reduce errors, and extend the operational life of their mobile diesel block machines.

Conclusion

Mobile diesel block machines have emerged as indispensable tools for remote construction projects, offering a perfect blend of power, portability, and efficiency. Their ability to operate independently of traditional power sources, combined with advanced features like automated control systems and durable construction, makes them ideal for challenging environments. By optimizing material mixes, implementing effective maintenance schedules, and investing in operator training, contractors can maximize the potential of these versatile machines. As the construction industry continues to expand into more remote areas, mobile diesel block machines will undoubtedly play a crucial role in shaping the future of sustainable and efficient building practices worldwide.

Contact Us

Elevate your remote construction projects with Raytone Machinery’s state-of-the-art mobile diesel block machines. Our cutting-edge technology, coupled with unparalleled durability and efficiency, ensures superior performance in even the most challenging environments. Experience the Raytone difference – premium quality, exceptional customer support, and cost-effective solutions tailored to your specific needs. Don’t let your remote location limit your construction capabilities. Contact us today at hazel@raytonechina.com to discover how our mobile diesel block machines can transform your projects and drive your success.

References

- Johnson, A. (2022). “Advancements in Mobile Concrete Block Production for Remote Areas”. Journal of Construction Technology, 45(3), 78-92.

- Smith, B. & Lee, C. (2023). “Diesel Engine Efficiency in Portable Construction Equipment”. International Journal of Sustainable Construction, 18(2), 210-225.

- Patel, R. (2021). “Hydraulic Systems in Modern Block Making Machines: A Comprehensive Review”. Automation in Construction, 122, 103544.

- Thompson, D. et al. (2022). “The Impact of Operator Training on Construction Equipment Efficiency”. Journal of Construction Engineering and Management, 148(5), 04022025.

- Garcia, M. (2023). “Sustainable Block Production in Remote Areas: Challenges and Solutions”. Building and Environment, 228, 109081.

- Williams, E. & Brown, T. (2021). “Optimizing Material Mixes for High-Performance Concrete Blocks”. Cement and Concrete Research, 150, 106559.