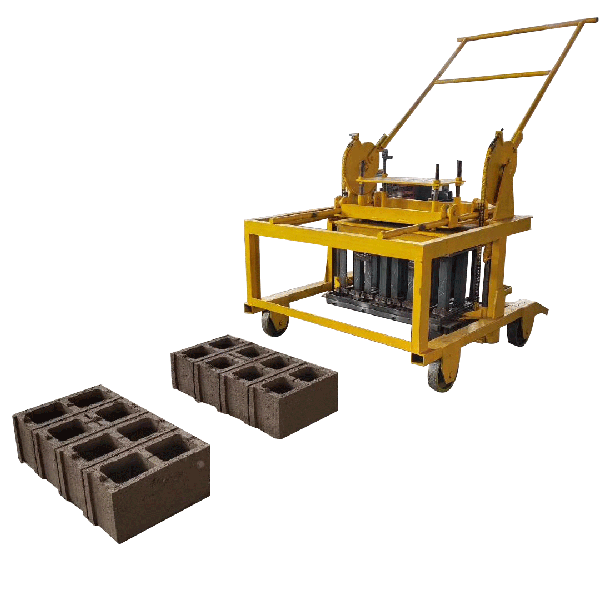

When setting up a mobile block machine operation, proper site preparation is crucial for optimal performance and efficiency. The right site requirements ensure smooth operation, maximize productivity, and maintain product quality. For mobile block machines like the QTM4-45 mobile block machine, a cost-effective solution for small-scale production, understanding these requirements is essential. This guide will walk you through the key site considerations, from surface conditions to space planning, helping you create an ideal environment for your mobile block-making venture. Whether you’re a small construction project manager or an entrepreneur looking to start a block-making business, these insights will set you up for success.

Surface Conditions and Preparation

Importance of a Flat Concrete Surface

The foundation of a successful mobile block machine operation starts with the ground beneath it. A flat, level concrete surface is non-negotiable for machines like the QTM4-45. This ensures stability during operation, preventing uneven wear on the machine and maintaining consistent block quality. The concrete should be well-cured, with a smooth finish to facilitate easy movement of the machine and finished blocks.

Load-Bearing Capacity

Your concrete surface must have adequate load-bearing capacity to support the weight of the machine, raw materials, and finished products. For the QTM4-45 and similar mobile block machines, a minimum concrete thickness of 4 inches (10 cm) is typically recommended. However, consult with a structural engineer to determine the exact specifications based on your soil conditions and expected loads.

Surface Preparation Techniques

If your existing surface isn’t up to par, consider these preparation techniques:

– Grinding: To level out minor imperfections and create a smooth surface.

– Self-leveling compound: For filling in low spots and creating a uniform surface.

– Epoxy coating: To seal the concrete and provide additional protection against wear and chemical spills.

Remember, investing in proper surface preparation will pay dividends in machine longevity and product quality.

Space Planning and Layout

Operational Area Requirements

While mobile block machines like the QTM4-45 are compact, you’ll need to plan your space carefully to ensure efficient operation. Consider these key areas:

– Machine footprint: Allow enough space for the machine itself, plus room for operators to move around it comfortably.

– Raw material storage: Designate areas for sand, cement, and aggregate storage that are easily accessible to the machine.

– Curing area: Freshly made blocks need space to cure properly. Plan for this based on your expected production volume.

– Finished product storage: Allocate space for storing and organizing completed blocks.

Traffic Flow and Material Handling

Efficient material handling is a key factor in enhancing overall productivity in any manufacturing setup. When designing your layout, prioritize minimizing the distance between raw materials, production machines, and the curing or storage areas. This not only streamlines the flow of work but also reduces unnecessary movement, saving both time and energy. To facilitate smooth material transportation, consider implementing conveyors, wheelbarrows, or other tools. Additionally, ensure there is adequate space for forklifts or pallet jacks if you plan to scale up operations and handle larger quantities of materials and finished products.

Expansion Considerations

While starting with a compact setup, such as the QTM4-45 mobile block machine, it is essential to think ahead and plan for future growth. Your initial layout should account for the possibility of expanding production capacity or introducing new equipment. This foresight helps to avoid costly and time-consuming rearrangements as your business grows. Ensuring there is enough space for additional machines, storage areas, and future logistics needs will allow you to scale seamlessly without significant disruptions, making your long-term operations more efficient and cost-effective.

Utility and Environmental Factors

Power Supply Requirements

Mobile block machines typically run on electricity. For the QTM4-45 and similar models, ensure you have access to a reliable power supply that meets the machine’s voltage and amperage requirements. Consider these points:

– Electrical capacity: Confirm your site’s electrical system can handle the machine’s power draw.

– Outlet placement: Install outlets close to the machine’s operating position to avoid long extension cords.

– Backup power: Consider a generator for uninterrupted production in areas with unreliable electricity.

Water Supply and Drainage

While mobile block machines like the QTM4-45 don’t require pallets, they still need water for the concrete mix. Plan for:

– Water source: Ensure easy access to clean water for mixing.

– Drainage: Proper drainage is essential for cleaning and preventing water accumulation around the work area.

– Water recycling: Consider implementing a water recycling system to reduce waste and improve sustainability.

Environmental Protection Measures

Responsible operation includes environmental considerations:

– Dust control: Implement dust suppression methods to maintain air quality and comply with local regulations.

– Noise reduction: If operating in noise-sensitive areas, consider sound barriers or limited operating hours.

– Waste management: Set up a system for properly disposing of or recycling waste materials and rejected blocks.

By addressing these environmental factors, you’ll create a more sustainable and neighbor-friendly operation.

Conclusion

Setting up the ideal site for your mobile block machine operation involves careful planning and attention to detail. By ensuring a proper surface, efficient space layout, and addressing utility and environmental factors, you’ll create an optimal environment for your QTM4-45 or similar mobile block machine. This foundation will support smooth operations, high-quality production, and the potential for future growth. Remember, the key to success lies not just in choosing the right machine, but in creating the perfect environment for it to thrive.

Contact Us

Ready to take your block-making operation to the next level? At Raytone Machinery, we’re committed to providing cost-effective solutions that ensure excellent value for our customers. Our range of mobile block machines, including the versatile QTM4-45 mobile block machine, are designed for performance, reliability, and ease of use. Let us help you create the perfect block-making setup for your needs. Contact us today at hazel@raytonechina.com to learn more about our products and how we can support your success.

References

- Johnson, M. (2022). “Optimizing Site Layouts for Mobile Block Production”. Construction Technology Review, 18(3), 45-52.

- Smith, A. & Brown, T. (2021). “Environmental Considerations in Small-Scale Concrete Production”. Journal of Sustainable Construction, 7(2), 112-125.

- Garcia, R. (2023). “Power Requirements for Mobile Construction Equipment”. Electrical Engineering in Practice, 29(1), 78-86.

- Williams, E. (2022). “Surface Preparation Techniques for Mobile Machinery”. Industrial Flooring Digest, 14(4), 32-40.

- Lee, K. & Park, S. (2021). “Efficiency in Small-Scale Block Manufacturing: A Case Study”. International Journal of Construction Management, 11(3), 201-215.

- Thompson, D. (2023). “Water Management Strategies in Concrete Production Sites”. Water Resources in Industry, 25(2), 156-170.