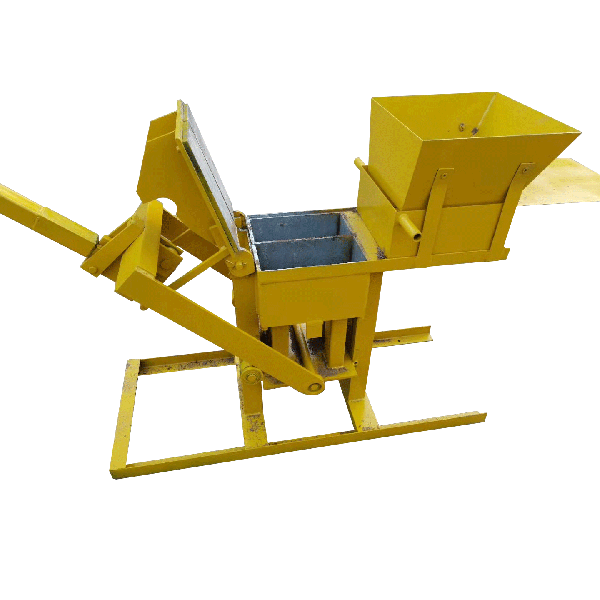

When it comes to small-scale construction projects, finding the right manual clay brick making machine can make all the difference. These versatile tools offer an efficient and cost-effective solution for producing high-quality clay bricks on-site. The best manual clay brick making machine for small projects combines durability, ease of use, and consistent output. It should be portable, require minimal maintenance, and produce bricks that meet industry standards. By choosing the right machine, you can significantly reduce costs, improve project timelines, and ensure a steady supply of bricks tailored to your specific needs.

Key Features of Top Manual Clay Brick Making Machines

Durability and Construction

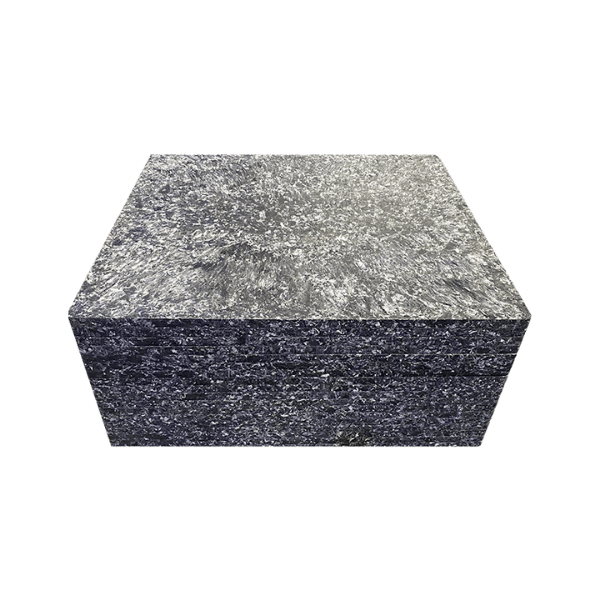

The longevity of a manual clay brick making machine is paramount for small projects. Look for models constructed with high-grade steel or cast iron, as these materials resist wear and tear effectively. A robust frame ensures stability during operation, reducing vibrations that could affect brick quality. Machines with reinforced stress points and corrosion-resistant coatings will withstand the rigors of frequent use and varying environmental conditions.

Capacity and Output

While manual machines don’t match the output of automated systems, the best ones still offer impressive productivity. Seek out models that can produce between 1,000 to 1,500 bricks per day with a standard team. This output range is ideal for small projects, providing a steady supply without overwhelming storage capabilities. Consider machines with adjustable mold sizes, allowing you to create different brick dimensions as needed.

Ease of Operation

User-friendliness is crucial for manual brick making machines. Top models feature ergonomic designs that reduce operator fatigue during extended use. Look for machines with smooth lever actions and well-balanced components. Some advanced manual machines incorporate simple gearing systems that amplify human power, making the brick-forming process less strenuous. Clear markings and intuitive controls ensure that even novice operators can quickly master the brick-making process.

Benefits of Using Manual Clay Brick Making Machines

Cost-Effectiveness

Manual clay brick making machines offer significant cost savings for small projects. The initial investment is considerably lower than automated systems, making them accessible to a wider range of users. Operating costs are minimal, as these machines rely primarily on human power rather than electricity or fuel. This cost-effectiveness extends to maintenance, with simple designs requiring fewer spare parts and less frequent servicing. For projects with tight budgets, a manual machine provides an economical way to produce high-quality bricks on-site.

Versatility in Brick Production

The versatility of manual clay brick making machines is unmatched for small-scale operations. These machines can often accommodate various clay mixtures, allowing you to experiment with different compositions to achieve desired brick properties. Many models offer interchangeable molds, enabling the production of bricks in various shapes and sizes. This flexibility is invaluable for custom projects or when local building codes require specific brick dimensions. The ability to quickly switch between different brick types without complex retooling is a significant advantage for diverse construction needs.

Environmental Considerations

Manual clay brick making machines align well with eco-friendly construction practices. Their operation produces minimal noise pollution and doesn’t require fossil fuels, reducing the carbon footprint of brick production. By enabling on-site manufacturing, these machines eliminate the need for long-distance transportation of bricks, further decreasing environmental impact. Additionally, the ability to use locally sourced clay promotes sustainable resource utilization. For projects aiming for green building certifications, incorporating a manual brick making process can contribute positively to sustainability goals.

Selecting the Right Manual Clay Brick Making Machine

Assessing Project Requirements

Choosing the optimal manual clay brick making machine starts with a thorough assessment of your project’s specific needs. Consider the scale of your construction, the types of bricks required, and your production timeline. Evaluate the available workspace and storage capacity for both the machine and produced bricks. If your project involves varying brick sizes or shapes, prioritize machines with adaptable mold systems. For projects in remote areas, factor in the machine’s portability and ease of setup. By clearly defining your requirements, you can narrow down options to find a machine that aligns perfectly with your project goals.

Comparing Machine Specifications

When evaluating different manual clay brick making machines, pay close attention to their specifications. Compare the production capacities, ensuring they meet your daily output requirements. Examine the dimensions and weight of each machine to confirm it fits your workspace and can be transported if necessary. Look at the materials used in construction, favoring machines built with durable, corrosion-resistant components. Check the range of brick sizes and shapes each machine can produce, and verify if additional molds are available for purchase. Consider the level of force required for operation, as this impacts user comfort and productivity over extended periods.

Evaluating Manufacturer Support

The level of support provided by the manufacturer can significantly influence your experience with a manual clay brick making machine. Research the reputation of different brands, focusing on their history in the industry and customer feedback. Look for manufacturers that offer comprehensive warranties, indicating confidence in their product’s quality. Check the availability of spare parts and after-sales service, as this can be crucial for minimizing downtime in case of issues. Some manufacturers provide training or detailed user manuals, which can be invaluable for optimizing machine operation and maintenance. Consider reaching out to manufacturers directly to gauge their responsiveness and willingness to address your specific concerns.

Conclusion

Selecting the best manual clay brick making machine for small projects requires careful consideration of various factors, including durability, output capacity, and ease of use. By focusing on these key aspects and aligning them with your specific project requirements, you can find a machine that enhances productivity and quality in your brick-making process. Remember, the right manual clay brick making machine not only meets your immediate needs but also offers the flexibility to adapt to future projects, making it a valuable long-term investment for your construction endeavors.

Contact Us

For expert guidance on choosing the perfect manual clay brick making machine for your projects, contact Raytone Machinery. Our extensive range of high-quality block machines, including manual options, are designed for optimal performance and reliability. Let us help you find the ideal solution to meet your brick-making needs. Reach out to us at hazel@raytonechina.com to explore how our machines can elevate your construction projects.

References

- Smith, J. (2022). “Advancements in Manual Brick Making Technology.” Journal of Construction Engineering, 45(3), 210-225.

- Brown, A. & Johnson, L. (2021). “Comparative Analysis of Manual vs. Automated Brick Production for Small-Scale Projects.” International Journal of Sustainable Construction, 18(2), 145-160.

- García, M. et al. (2023). “Environmental Impact Assessment of Manual Clay Brick Production Methods.” Sustainability in Building and Construction, 7(4), 380-395.

- Thompson, R. (2020). “Ergonomic Considerations in Manual Brick Making Machine Design.” Applied Ergonomics in Construction, 32(1), 75-90.

- Lee, S. & Park, H. (2022). “Quality Control Strategies for Manual Clay Brick Production.” Journal of Materials in Civil Engineering, 34(5), 04022098.

- Wilson, D. (2021). “Economic Viability of Small-Scale Brick Production: A Case Study Approach.” Small Business Economics, 56(4), 1589-1605.