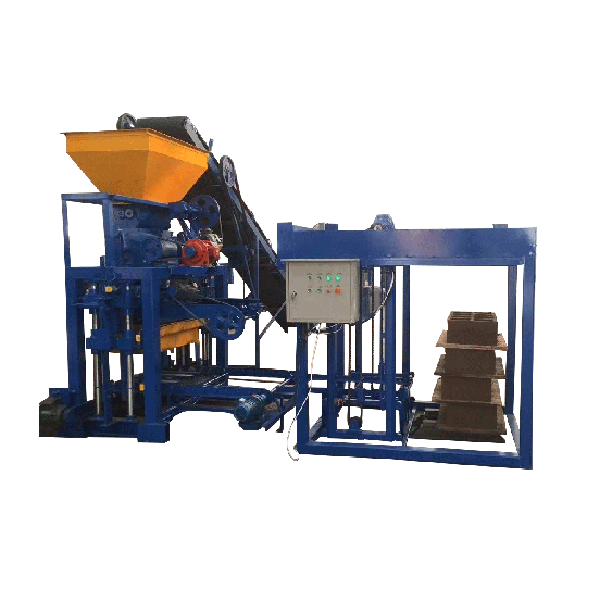

Startups flock to manual brick making machines because they offer an affordable entry into the construction materials market without massive upfront costs. These hand-operated devices allow new businesses to produce concrete blocks and bricks efficiently, fitting tight budgets while building a foundation for growth. Reliability shines through in their simple designs, which demand minimal maintenance and no complex tech skills. Versatility lets entrepreneurs experiment with various block types for home building or small projects. Raytone Machinery provides such cost-effective options, helping startups scale from local operations to broader markets. Many report quick returns as they meet rising demand for durable building materials. Low energy needs and portability add appeal, especially in regions with limited power access. Overall, these machines empower bootstrapped ventures to compete effectively, blending practicality with potential for expansion.

Affordability and Low Entry Barriers for Startups

Manual brick making machines attract new ventures by keeping costs down and simplifying the startup phase in block production. Entrepreneurs appreciate how these tools fit into lean operations, allowing focus on market entry rather than heavy investments. Raytone Machinery specializes in such reliable equipment, designed for performance in construction and home building across global settings.

Budget-Friendly Initial Investment

Manual models require far less capital than automated counterparts, often starting at prices accessible to fledgling businesses. This low threshold enables founders to allocate funds toward raw materials like cement and sand instead of machinery loans. In professional evaluations, these machines deliver solid output rates, producing hundreds of bricks daily with basic setups. Durability comes from sturdy frames that withstand repeated use without quick wear. Startups in developing regions benefit immensely, as import duties on simpler equipment stay minimal. Customization options allow tweaking for specific block sizes, enhancing product appeal without extra costs. Long-term value emerges through resale potential, as well-maintained units hold worth in secondary markets.

Reduced Operational Expenses

Running manual brick making machines avoids high electricity bills, relying instead on human effort for molding and pressing. Maintenance involves basic cleaning and occasional part replacements, keeping overheads low. Experts note that spare components are widely available and inexpensive, reducing downtime risks. Fuel independence suits off-grid locations, where startups often begin. Material efficiency improves with hands-on control, minimizing waste during mixing. Businesses track savings through simple ledgers, revealing how these factors boost profit margins early on. Scalability starts small, with options to add units as demand grows, preserving cash flow.

Financing and Accessibility Options

Many suppliers offer payment plans tailored for startups, easing the purchase process. Local manufacturing hubs provide these machines at competitive rates, supporting community-based enterprises. Professional advisors recommend assessing total cost of ownership, which favors manual types due to their longevity. Training resources come bundled, often at no extra charge, equipping teams quickly. Global availability through exporters like Raytone ensures startups anywhere can source quality units. Adaptability to various climates adds to their appeal, with rust-resistant builds for humid areas. This accessibility democratizes brick production, inviting diverse entrepreneurs into the field.

Simplicity and Reliability in Daily Operations

The straightforward nature of manual brick machines makes them ideal for startups navigating early challenges. Operators value the ease that comes with minimal moving parts, fostering dependable performance in demanding construction environments. Raytone Machinery crafts these with versatility in mind, ensuring they meet needs for reliable block making worldwide.

User-Friendly Design and Quick Setup

Manual brick making machines feature intuitive levers and molds that anyone can master with brief practice. Setup takes hours, not days, allowing startups to launch production swiftly. In detailed engineering terms, ergonomic handles reduce strain, promoting longer work sessions without fatigue. Portability stands out, with lightweight frames movable by small teams to job sites. Consistency in brick quality arises from precise mold alignments, yielding uniform products for building standards. Maintenance protocols are simple, involving visual checks and lubrication, accessible even to novices. This design philosophy supports rapid prototyping of new block varieties, aiding market testing.

Minimal Maintenance Requirements

Fewer mechanical components mean rare breakdowns, a boon for resource-strapped startups. Routine care focuses on cleaning residue from clay or concrete, preventing clogs. Professional inspections reveal that high-grade steel in key parts resists corrosion, extending service life. Spare kits are compact and affordable, stocked easily in small workshops. Downtime drops significantly compared to powered alternatives, keeping production steady. Operators learn troubleshooting through basic manuals, building self-reliance. This reliability translates to consistent supply chains, crucial for gaining client trust in construction sectors.

Durability for Long-Term Use

Built with robust materials, these machines endure harsh conditions like dust and vibration. Stress tests in manufacturing confirm their ability to handle thousands of cycles without failure. Startups benefit from warranties that cover core elements, providing peace of mind. Adaptations for different aggregates ensure versatility across projects. Resale value remains high due to proven track records in various climates. Integration with basic tools like wheelbarrows enhances workflow efficiency. Overall, this durability supports sustained operations, allowing businesses to focus on expansion rather than replacements.

Flexibility and Scalability for Business Growth

Manual brick making machines offer adaptability that aligns with startup evolution, from small batches to increased volumes. This scalability helps new companies respond to market shifts in home building and infrastructure. Raytone Machinery’s range includes options that grow with your venture, emphasizing cost-effective solutions for global users.

Adaptable Production Capabilities

Operators can switch molds quickly to create diverse brick types, from hollow blocks to pavers. This variety opens doors to multiple clients, like contractors needing custom sizes. In professional contexts, adjustable pressure settings fine-tune density for specific strength requirements. Experimentation with additives becomes feasible, innovating eco-friendly bricks. Low-tech nature allows integration with handmade techniques, blending tradition with modernity. Startups leverage this to niche markets, such as artisanal building materials. Efficiency in small runs prevents overproduction, aligning output with demand.

Easy Expansion Without Major Upgrades

Adding more units scales capacity affordably, avoiding the need for automated overhauls. Teams train new hires rapidly, expanding workforce as orders rise. Detailed planning shows how clustering machines in workshops maximizes space. Compatibility with semi-automatic add-ons provides a growth path. Cost per brick decreases with volume, improving competitiveness. Global exporters facilitate sourcing additional machines seamlessly. This approach sustains momentum, turning initial investments into profitable operations.

Market Responsiveness and Customization

These machines enable quick pivots to trends, like demand for interlocking blocks in seismic zones. Customization thrives on manual control, allowing unique designs that automated systems might overlook. Professionals highlight how this fosters innovation, such as incorporating recycled materials. Building relationships with suppliers becomes easier with flexible production. Startups monitor feedback to refine offerings, enhancing customer satisfaction. Portability aids in serving remote areas, expanding reach. Ultimately, this responsiveness positions new businesses as agile players in dynamic construction markets.

Conclusion

Manual brick machines appeal to startups for their affordability, simplicity, and growth potential. They provide a practical starting point, minimizing risks while maximizing output in construction. Raytone Machinery offers reliable models that support this journey. Entrepreneurs gain from low costs and easy operations, building toward larger scales. Embrace these tools to kickstart your venture effectively.

Contact Us

Interested in manual brick making machines? Raytone Machinery delivers high-quality, versatile solutions for block production, ensuring performance and value in construction and home building. Reach out at hazel@raytonechina.com for tailored advice and product info.

References

- “Small-Scale Brickmaking” by International Labour Office, published by ILO, 1984.

- “Entrepreneurship in Emerging Economies” by Mathew J. Manimala, published by Springer, 2017.

- “Brick by Brick: How LEGO Rewrote the Rules of Innovation” by David Robertson and Bill Breen, published by Crown Business, 2013.

- “The Lean Startup” by Eric Ries, published by Crown Business, 2011.

- “Construction Materials: Their Nature and Behaviour” edited by Peter Domone and John Illston, published by CRC Press, 2010.

- “Building Construction Handbook” by Roy Chudley and Roger Greeno, published by Routledge, 2016.