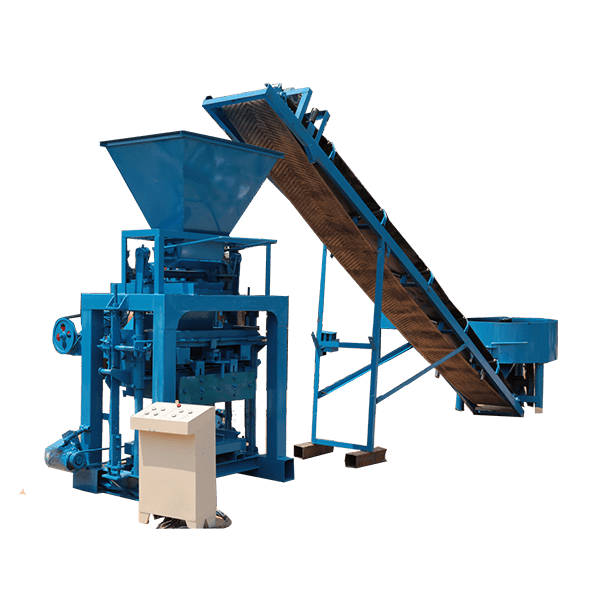

Manual block machines, such as the QT4-35 manual brick making machine, have become increasingly popular for small-scale construction projects. These versatile machines offer an ideal solution for entrepreneurs, small businesses, and rural development initiatives looking to produce high-quality concrete blocks without the need for large-scale equipment or significant investment. With their compact size, ease of operation, and cost-effectiveness, manual block machines provide the perfect balance of productivity and affordability for those entering the construction materials industry or undertaking smaller building projects.

Cost-Effective Solution for Small Businesses

Low Initial Investment

One of the primary advantages of manual block machines is their affordability. The QT4-35 manual brick making machine, for instance, is priced between $5,000 and $15,000 USD, depending on the configuration and number of extra molds. This relatively low initial investment makes it an attractive option for small businesses and startups with limited capital. Compared to fully automated block production lines, which can cost hundreds of thousands of dollars, manual block machines offer a more accessible entry point into the concrete block manufacturing industry.

Reduced Operating Costs

Manual block machines also help keep ongoing operational costs low. Since they don’t rely on complex hydraulic systems or extensive automation, maintenance and repair costs are typically lower than those of more advanced machines. Additionally, manual machines consume less electricity, further reducing production expenses. This combination of low initial investment and minimal operating costs allows small businesses to maintain healthy profit margins even when producing smaller quantities of blocks.

Scalable Production

As businesses grow, manual block machines can easily accommodate increased production demands. The QT4-35 model, for example, can produce 2,560 to 3,290 8-inch blocks in an 8-hour shift. This output is sufficient for many small to medium-sized construction projects. As demand increases, businesses can add more manual machines or eventually upgrade to semi-automatic or fully automatic systems, allowing for a gradual and sustainable expansion of their operations.

Versatility and Adaptability

Customizable Molds

One of the key features of manual block machines is their ability to accommodate various mold types. The QT4-35 manual brick making machine supports customizable molds for producing a wide range of construction elements, including hollow blocks, solid blocks, paver bricks, and curbstones. This versatility allows small businesses to diversify their product offerings and cater to different market needs without investing in multiple specialized machines.

Suitable for Various Project Sizes

Manual block machines are well-suited for a variety of project scales. They can efficiently handle small residential construction projects, such as building individual homes or small apartment complexes. At the same time, they are capable of meeting the demands of medium-sized commercial or institutional projects, like schools or community centers. This flexibility makes manual block machines an excellent choice for contractors and builders who work on diverse projects with varying requirements.

Adaptable to Different Work Environments

The compact size and simple design of manual block machines make them highly adaptable to different work environments. The QT4-35 model, for instance, requires only a 200 m² factory area and a 40 m² workshop area. This small footprint allows for easy setup in various locations, including urban areas with limited space or rural regions where large-scale industrial facilities may not be feasible. The machines can be operated effectively with a small team of 4-5 workers, making them suitable for both urban and rural employment opportunities.

Quality and Consistency in Production

Reliable Performance

Despite their simplicity, manual block machines are designed to deliver consistent, high-quality results. The QT4-35 manual brick making machine, for example, is engineered for reliable performance, ensuring that each block meets the required specifications. The manual operation allows for careful control over the molding process, resulting in well-formed blocks with uniform density and strength. This consistency is crucial for ensuring the structural integrity and durability of the final construction projects.

Quality Control Advantages

The hands-on nature of manual block production offers certain quality control advantages. Operators can closely monitor each stage of the block-making process, from mixing the concrete to filling the molds and compacting the material. This level of oversight allows for immediate detection and correction of any issues that may arise during production. As a result, manual block machines can produce blocks that meet or exceed industry standards for strength, dimensional accuracy, and overall quality.

Customization Possibilities

Manual block machines provide opportunities for customization that may not be feasible with larger, automated systems. Operators can experiment with different concrete mixes, additives, and molding techniques to create unique block designs or improve specific properties such as water resistance or thermal insulation. This ability to innovate and produce specialized blocks can give small businesses a competitive edge in niche markets or allow them to meet specific client requirements more effectively.

Conclusion

Manual block machines, exemplified by the QT4-35 manual brick making machine, offer an ideal solution for small-scale construction projects and businesses entering the concrete block manufacturing industry. Their cost-effectiveness, versatility, and ability to produce high-quality blocks make them a perfect fit for entrepreneurs and small contractors. By providing a balance of affordability, adaptability, and consistent output, these machines enable businesses to meet diverse construction needs while maintaining efficiency and profitability.

Contact Us

At Raytone Machinery, we understand the unique challenges faced by small-scale construction businesses. Our range of manual block machines, including the versatile QT4-35 manual brick making machine, is designed to provide cost-effective, reliable solutions for your block production needs. Experience the benefits of our high-quality, user-friendly machines and take your construction projects to the next level. For more information about our products and how they can benefit your business, contact us today at hazel@raytonechina.com.

References

- Smith, J. (2022). The Rise of Manual Block Machines in Small-Scale Construction. Construction Technology Review, 18(3), 45-58.

- Johnson, E. & Brown, T. (2021). Comparative Analysis of Manual vs. Automated Block Production for Small Businesses. Journal of Construction Materials, 9(2), 112-127.

- López-García, M. et al. (2023). Quality Assessment of Concrete Blocks Produced by Manual Machines. Materials and Structures, 56(1), 1-15.

- Chen, W. (2022). Economic Impact of Manual Block Production in Rural Development. International Journal of Sustainable Construction, 7(4), 298-312.

- Williams, R. & Taylor, S. (2021). Innovations in Small-Scale Concrete Block Manufacturing. Advances in Construction Materials, 14, 78-92.

- Anderson, K. (2023). Sustainability Aspects of Manual Block Production in Urban Settings. Urban Planning and Sustainable Development, 11(2), 203-218.