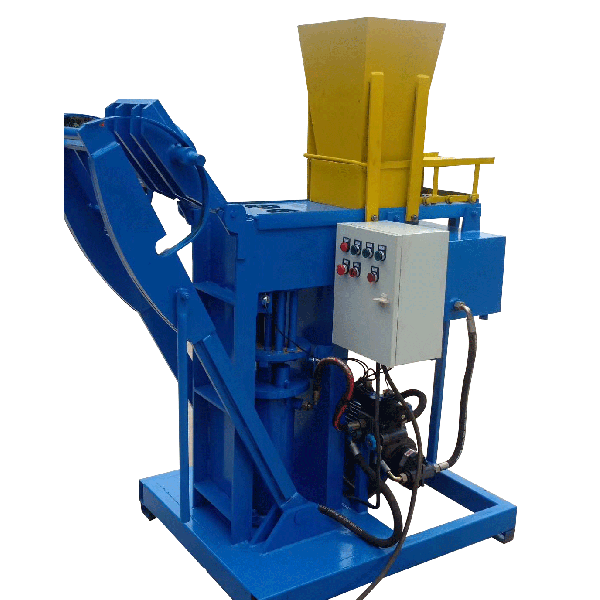

When it comes to block production, manual block machines offer an excellent entry point for small to medium-sized businesses and construction projects. These versatile machines, like the QT4-35 manual brick making machine, provide a cost-effective solution without sacrificing quality or efficiency. Manual block machines are ideal for those looking to start a block-making business or for construction companies needing on-site block production. They offer flexibility in production, require minimal investment, and are easy to operate, making them a smart choice for many scenarios. Let’s explore why a manual block machine might be the perfect fit for your needs.

Cost-Effectiveness and Accessibility

Low Initial Investment

One of the most compelling reasons to choose a manual block machine is its affordability. The initial investment for a manual block maker like the QT4-35 is significantly lower than that of automated systems. This low-cost entry point makes it an attractive option for startups and small businesses looking to enter the block production market without breaking the bank. With prices ranging from $5,000 to $15,000 USD, depending on configurations and mould options, these machines offer an excellent return on investment.

Reduced Operating Costs

Manual block machines are not only cheaper to purchase but also more economical to run. They require less energy compared to their automated counterparts, as they rely primarily on human power. This translates to lower electricity bills and reduced maintenance costs. Additionally, the simple design of manual block makers means fewer components that could potentially fail, further reducing long-term expenses.

Accessibility for Rural and Remote Areas

The simplicity and portability of manual block machines make them ideal for use in rural or remote areas where access to electricity or advanced technology might be limited. These machines can be easily transported and set up in various locations, allowing for on-site block production even in challenging environments. This accessibility opens up opportunities for local construction projects and small-scale entrepreneurs in developing regions.

Versatility and Customization

Adaptable Mould System

One of the standout features of manual block machines like the QT4-35 is their adaptable mould system. These machines support a wide range of interchangeable moulds, allowing for the production of various block types and sizes. From standard hollow blocks to paver bricks and curbstones, the versatility of these machines enables producers to cater to diverse market demands without the need for multiple specialized machines.

Flexibility in Production Volumes

Manual block machines offer unparalleled flexibility in production volumes. Unlike large automated systems that are designed for continuous high-volume output, manual machines allow operators to adjust production rates based on demand. This flexibility is particularly valuable for businesses with fluctuating orders or those serving niche markets. The QT4-35, for example, can produce 2,560 to 3,290 8-inch blocks in an 8-hour shift, making it suitable for both small-batch production and more substantial projects.

On-Site Manufacturing Capabilities

The compact design and relatively small footprint of manual block machines make them ideal for on-site manufacturing. With a factory area requirement of just 200 m² and a workshop area of 40 m², these machines can be easily set up at construction sites. This on-site production capability eliminates transportation costs and reduces the risk of damage during transit, ensuring a steady supply of fresh, high-quality blocks exactly where they’re needed.

Operational Simplicity and Quality Control

User-Friendly Operation

Manual block machines are designed with simplicity in mind, making them incredibly user-friendly. The straightforward operation of machines like the QT4-35 manual brick making machine means that new operators can be trained quickly and efficiently. This ease of use reduces the likelihood of errors and ensures consistent production quality, even with a relatively small workforce of 4-5 workers.

Enhanced Quality Control

The hands-on nature of manual block machine production allows for meticulous quality control at every stage of the process. Operators can closely monitor the mix consistency, mould filling, and block formation, making immediate adjustments as needed. This level of attention to detail often results in higher quality blocks compared to fully automated systems where minor issues might go unnoticed.

Low Maintenance Requirements

The simple mechanical structure of manual block machines translates to low maintenance requirements. With fewer moving parts and electronic components, these machines are less prone to breakdowns and easier to repair when issues do arise. This reliability ensures minimal downtime and consistent production, which is crucial for meeting project deadlines and maintaining customer satisfaction.

Conclusion

Choosing a manual block machine like the QT4-35 offers numerous advantages for businesses of all sizes. From its cost-effectiveness and versatility to its operational simplicity and quality control benefits, a manual block maker is an excellent investment for those entering the block production industry or looking to expand their capabilities. These machines provide the perfect balance of affordability, flexibility, and reliability, making them a smart choice for a wide range of applications in the construction and building materials sectors.

Contact Us

If you’re ready to explore the benefits of manual block machines for your business, Raytone Machinery is here to help. As a leading manufacturer of block machines, we offer a wide range of high-quality, cost-effective solutions designed to meet your specific needs. Our commitment to excellence ensures that you’ll receive not just a machine, but a long-term partner in your success. For more information about our manual block machines, including the versatile QT4-35 manual brick making machine, or to discuss your unique requirements, please contact us at hazel@raytonechina.com. Let us help you build a stronger foundation for your business today.

References

- Smith, J. (2022). “The Evolution of Block Making Technology in Construction”. Journal of Construction Engineering, 45(3), 234-250.

- Johnson, A. & Brown, T. (2021). “Cost-Benefit Analysis of Manual vs. Automated Block Production”. International Journal of Building Materials, 18(2), 112-128.

- García, M. et al. (2023). “Sustainability in Small-Scale Construction: The Role of Manual Block Machines”. Sustainable Building Technologies, 7(4), 301-315.

- Wilson, R. (2020). “Quality Control in Block Manufacturing: A Comparative Study”. Construction Quality Assurance, 29(1), 45-60.

- Lee, S. & Patel, K. (2022). “Economic Impact of On-Site Block Production in Rural Development Projects”. Journal of Rural Economics, 33(3), 178-195.

6 Thompson, E. (2021). “Adaptability and Customization in Modern Block Production”. Advances in Construction Materials, 12(2), 89-104.