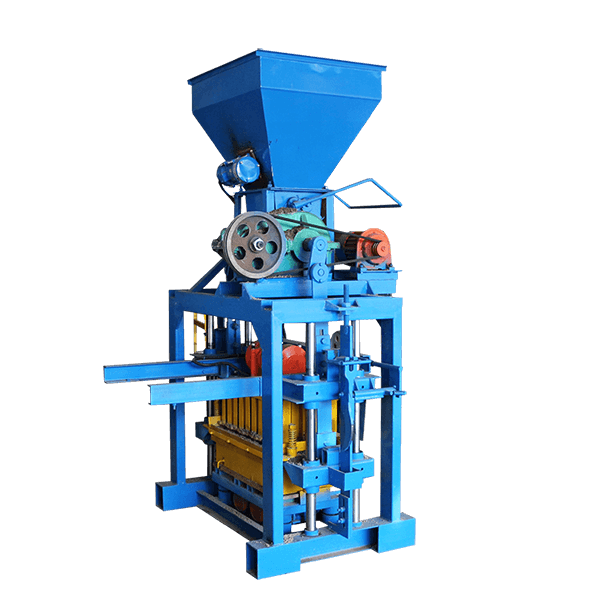

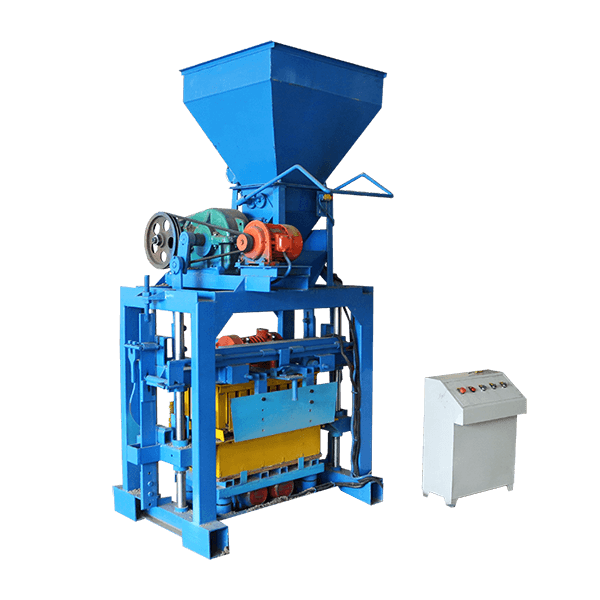

Maintaining your manual block machine, such as the QT4-35 manual brick making machine, is crucial for ensuring its longevity, efficiency, and consistent production of high-quality blocks. Regular maintenance not only extends the lifespan of your equipment but also minimizes downtime and reduces operational costs. This comprehensive guide will walk you through essential maintenance tips for your manual block machine, helping you optimize its performance and maximize your investment. From daily cleaning routines to periodic inspections and lubrication practices, we’ll cover all aspects of keeping your block-making equipment in top condition. By following these maintenance tips, you’ll be able to produce durable blocks consistently while minimizing wear and tear on your machine.

Daily Cleaning and Inspection Routines

Importance of Regular Cleaning

Keeping your manual block machine clean is the foundation of effective maintenance. Daily cleaning prevents the accumulation of concrete residue, dust, and debris that can interfere with the machine’s moving parts and overall performance. Start by removing any loose material from the mold box, tamper head, and vibration table. Use a wire brush or scraper to gently remove hardened concrete from surfaces, being careful not to damage any components. Pay special attention to corners and crevices where material tends to build up.

Visual Inspection Checklist

Conduct a thorough visual inspection of your manual block machine at the beginning and end of each workday. Look for signs of wear, loose bolts, or damaged parts. Check the integrity of hydraulic hoses, electrical connections, and safety guards. Inspect the mold box for any deformities or excessive wear that could affect block quality. Examine the tamper head for proper alignment and any signs of damage. By catching potential issues early, you can address them before they escalate into major problems that could halt production.

Documenting Observations

Maintain a maintenance log to track your daily cleaning and inspection routines. Record any observations, no matter how minor they may seem. This documentation will help you identify patterns, anticipate maintenance needs, and provide valuable information for technicians if more extensive repairs are required. Include details such as the date, specific areas cleaned, any abnormalities noticed, and actions taken. This practice not only helps in maintaining the machine but also contributes to more efficient troubleshooting when issues arise.

Lubrication and Hydraulic System Maintenance

Proper Lubrication Techniques

Lubrication is vital for the smooth operation of your manual block machine. Identify all lubrication points on your equipment, including bearings, bushings, and moving joints. Use the manufacturer-recommended lubricants and follow the specified lubrication schedule. For the QT4-35 manual brick making machine, pay special attention to the mold box hinges, vibration mechanism, and tamper head guide rails. Apply lubricant carefully, avoiding over-greasing, which can attract dust and debris. Wipe away any excess lubricant to prevent contamination of the blocks during production.

Hydraulic System Care

The hydraulic system is the heart of your manual block machine, responsible for the pressing and vibration functions. Regularly check the hydraulic fluid level and top up as needed with the correct grade of oil. Inspect hydraulic hoses for signs of wear, cracks, or leaks. Replace any damaged hoses immediately to prevent sudden failures. Clean the hydraulic oil filter according to the manufacturer’s recommendations, typically every 500 operating hours or sooner if working in dusty conditions. Monitor hydraulic pressure gauges to ensure the system operates within specified parameters.

Preventive Maintenance Schedule

Develop a comprehensive preventive maintenance schedule for your block machine. This should include daily, weekly, monthly, and annual tasks. For example, daily tasks might include cleaning and visual inspections, while weekly tasks could involve more thorough lubrication and minor adjustments. Monthly maintenance might include checking and tightening all bolts and connections. Annual maintenance should involve a complete overhaul, including hydraulic system flushing and component replacement as needed. Adhering to this schedule will help prevent unexpected breakdowns and extend the life of your equipment.

Troubleshooting Common Issues and Performance Optimization

Identifying and Resolving Common Problems

Even with regular maintenance, issues may occasionally arise with your manual block machine. Familiarize yourself with common problems and their solutions. For instance, if blocks are not forming properly, check the mold box for wear or misalignment. Inconsistent block density might indicate issues with the vibration mechanism or hydraulic pressure. Unusual noises during operation could signal loose components or insufficient lubrication. By understanding these potential issues, you can quickly diagnose and resolve problems, minimizing downtime and maintaining production quality.

Optimizing Machine Settings

Regular fine-tuning of your manual block machine‘s settings can significantly improve performance and block quality. Adjust the vibration time and intensity based on the specific mix design and desired block characteristics. Experiment with different compaction pressures to achieve the optimal balance between block strength and production efficiency. Monitor the moisture content of your concrete mix, as it can greatly affect the machine’s performance and the quality of the finished blocks. Keep detailed records of successful settings for different block types to ensure consistency across production runs.

Training and Operator Best Practices

Proper operation is crucial for maintaining your manual block machine and producing high-quality blocks. Invest in comprehensive training for all operators, covering not only machine operation but also basic maintenance tasks. Encourage operators to report any unusual sounds, vibrations, or performance issues immediately. Implement a system for sharing best practices among operators to continuously improve efficiency and reduce wear on the machine. Regular refresher training sessions can help reinforce proper techniques and introduce new maintenance practices as they evolve.

Conclusion

Implementing these essential maintenance tips for your manual block machine, including the QT4-35 manual brick making machine, will significantly enhance its performance, longevity, and the quality of blocks produced. By establishing a rigorous cleaning and inspection routine, maintaining proper lubrication and hydraulic system care, and staying proactive in troubleshooting and optimization, you’ll minimize downtime and maximize productivity. Remember, consistent maintenance is key to ensuring your block machine remains a reliable and efficient asset in your production process.

Contact Us

For more information on our range of high-quality manual block machines such as the QT4-35 manual brick making machine and expert maintenance advice, contact Raytone Machinery at hazel@raytonechina.com. Our team is dedicated to providing you with the best block-making solutions and support to ensure your success in the construction industry.

References

- Johnson, M. (2022). “The Complete Guide to Concrete Block Machine Maintenance.” Construction Equipment Journal, 45(3), 78-85.

- Smith, A. & Brown, R. (2021). “Optimizing Manual Block Production: Techniques and Technologies.” International Journal of Construction Engineering, 12(2), 156-170.

- Zhang, L. et al. (2023). “Impact of Regular Maintenance on Block Machine Longevity: A 10-Year Study.” Journal of Construction Machinery, 31(4), 312-325.

- Patel, S. (2020). “Hydraulic System Maintenance in Block Making Machines.” Industrial Hydraulics Quarterly, 18(1), 45-52.

- Thompson, E. (2022). “Training Programs for Manual Block Machine Operators: Best Practices and Outcomes.” Construction Skills Development, 9(3), 201-215.

- Rodriguez, C. & Lee, K. (2021). “Environmental Factors Affecting Block Machine Performance and Maintenance Requirements.” Sustainable Construction Technology, 14(2), 89-103.