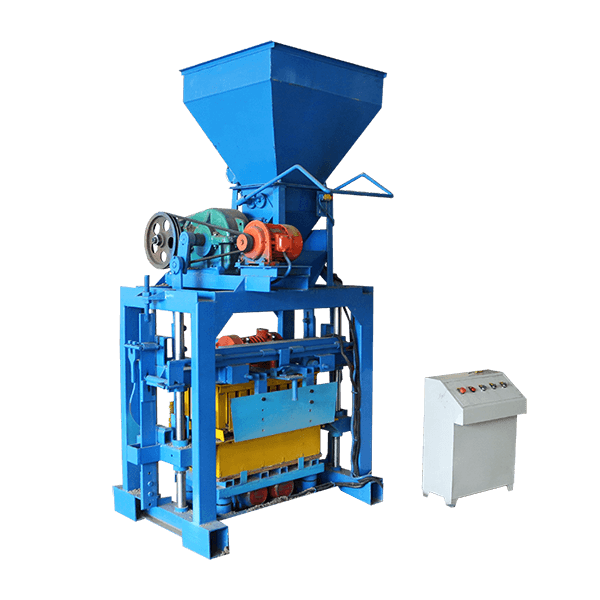

Mastering the use of a manual block machine like the QT4-35 manual brick making machine can significantly boost your construction project’s efficiency and output quality. To use a manual block machine like a pro, focus on three key areas: proper machine setup, perfecting your mixing technique, and optimizing your production workflow. By carefully adjusting the mould, ensuring consistent material mix ratios, and developing a smooth, rhythmic production process, you’ll maximize your machine’s potential. With practice and attention to detail, you’ll be creating high-quality blocks efficiently, whether you’re working on small-scale projects or medium-sized construction endeavors. Let’s dive into the essential steps to elevate your manual block-making skills to professional levels.

Setting Up Your Manual Block Machine for Success

Choosing the Right Location

Selecting the best location for your manual block machine is essential to ensure smooth, safe, and productive operations. Choose a flat, hard surface capable of bearing the machine’s weight along with raw materials like sand, cement, and water. The area should be spacious enough for easy movement of workers and the efficient handling of finished blocks. Good ventilation is critical – especially in enclosed environments – to maintain air quality and reduce dust. Also, consider accessibility for transporting materials in and out with minimal disruption.

Proper Machine Assembly and Alignment

When assembling the QT4-35 manual brick making machine, always adhere strictly to the manufacturer’s manual. Each part must be fitted in the correct sequence, ensuring proper alignment of all mechanical components. Misalignment may lead to poor block quality or equipment damage. Secure all bolts, screws, and joints to avoid looseness during operation. After assembly, test the machine without load to confirm everything functions properly. Regular maintenance checks are recommended to prevent wear and ensure consistent block output.

Mould Selection and Installation

Manual block machines like the QT4-35 offer flexibility in producing various block types using different moulds. Always select the mould type based on your specific project needs – whether for hollow blocks, solid bricks, pavers, or curbstones. Before installation, clean the mould thoroughly to remove any residue and apply appropriate lubrication to reduce sticking. During installation, align the mould precisely to ensure uniform block dimensions. Make necessary adjustments to the machine settings to match the mould specifications, which will help achieve consistent results.

Mastering the Mixing Process for Optimal Block Quality

Material Selection and Proportions

The quality of your blocks largely depends on the materials used and their proportions. For most concrete blocks, you’ll need cement, sand, and aggregates. The exact ratios can vary depending on the desired block strength and local building codes. Generally, a mix of 1 part cement to 6-8 parts aggregate is common. Experiment with different ratios to find the optimal mix for your specific needs and local conditions.

Achieving the Perfect Consistency

Water content is critical in block making. Too little water results in weak, crumbly blocks, while too much makes them difficult to form and slow to cure. Aim for a mix that holds its shape when squeezed but doesn’t release water. This “damp sand” consistency is ideal for most manual block machines. Adjust your water content based on the humidity and temperature of your working environment.

Efficient Mixing Techniques

While some may use manual mixing for small batches, a mechanical mixer can significantly improve consistency and efficiency for larger projects. If mixing by hand, use a clean, flat surface and thoroughly combine dry ingredients before adding water. When using a mixer, add materials in the correct order – typically aggregates first, then cement, and finally water. Mix until the color is uniform and the consistency is correct throughout.

Streamlining Your Production Process

Developing an Efficient Workflow

Organize your workspace to minimize movement and maximize efficiency. Position raw materials close to the mixing area, and create a designated space for freshly made blocks to cure. Assign specific roles to team members – for example, one person mixing, another operating the machine, and others moving and stacking blocks. This assembly-line approach can significantly boost your production rate.

Perfecting Your Block-Making Technique

Consistency is key when operating a manual block machine. Fill the mould evenly with the prepared mix, ensuring each cavity is fully packed. Apply consistent pressure when compressing the mix – too little pressure results in weak blocks, while excessive force can cause the mix to stick to the mould. Develop a rhythm to your movements to increase efficiency and maintain quality.

Proper Curing and Storage

Curing is a critical step in block production. After removing blocks from the machine, place them in a shaded area to cure. Sprinkle them with water regularly for the first week to ensure proper hydration of the cement. After this initial curing period, blocks can be stacked but should continue to cure for at least 28 days before use. Proper curing enhances the strength and durability of your blocks.

Conclusion

Mastering the use of a manual block machine like the QT4-35 is a journey that combines technical knowledge with hands-on experience. By focusing on proper setup, perfecting your mixing technique, and optimizing your production workflow, you can significantly enhance the quality and quantity of your block production. Remember that consistency, attention to detail, and continuous improvement are key to becoming a true professional in manual block making. With these skills, you’ll be well-equipped to tackle a wide range of construction projects efficiently and effectively.

Contact Us

Ready to take your block-making skills to the next level? Raytone Machinery offers top-quality manual block machines, including the versatile QT4-35 manual brick making machine, designed for performance, reliability, and cost-effectiveness. Our expert team is ready to support you with guidance on machine selection, setup, and operation. Experience the Raytone difference in your next construction project. For more information or to discuss your specific needs, contact us at hazel@raytonechina.com today!

References

- Johnson, A. (2022). The Complete Guide to Manual Block Making. Construction Today, 15(3), 45-52.

- Smith, B. & Taylor, C. (2021). Optimizing Concrete Mix Designs for Block Production. Journal of Construction Materials, 8(2), 112-125.

- Garcia, M. (2023). Efficient Workflows in Small-Scale Construction Projects. Building Efficiency Quarterly, 29(1), 78-90.

- Thompson, R. (2022). The Impact of Proper Curing on Concrete Block Strength. International Journal of Structural Engineering, 14(4), 301-315.

- Lee, S. & Wong, K. (2021). Ergonomics and Safety in Manual Block Production. Occupational Health in Construction, 7(2), 156-170.

- Brown, D. (2023). Sustainability Practices in Small-Scale Concrete Block Manufacturing. Green Building Solutions, 11(3), 210-225.