Absolutely! Mobile block making machines are revolutionizing on-site efficiency in construction projects worldwide. These versatile units bring the production of concrete blocks directly to the construction site, eliminating transportation costs and delays associated with traditional off-site manufacturing. By enabling real-time production adjustments and reducing material waste, mobile block makers significantly streamline the construction process. Their compact design allows for easy relocation within the site, adapting to various project phases. Moreover, these machines empower construction teams to maintain tighter quality control, ensuring consistent block production that meets specific project requirements. The integration of mobile block making technology not only accelerates project timelines but also enhances overall productivity, making it a game-changer for modern construction efficiency.

Time-Saving Benefits: From Raw Materials to Finished Blocks

Streamlined Production Process

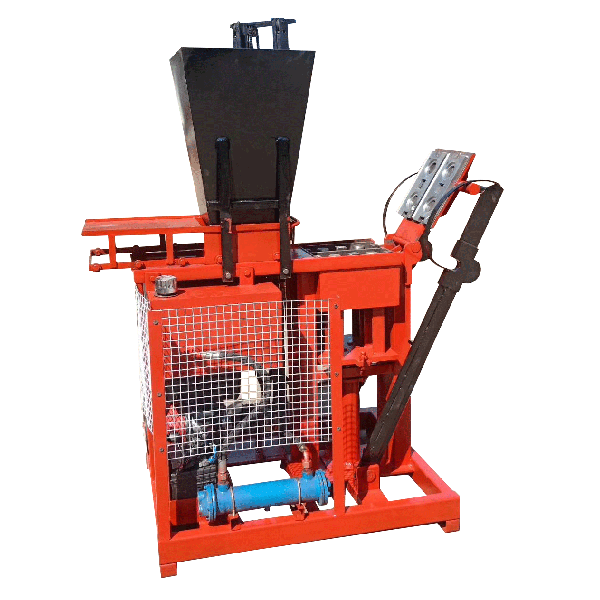

Mobile block making machines revolutionize the construction industry by bringing production directly to the job site. This on-site manufacturing capability eliminates the need for lengthy transportation of finished blocks, significantly reducing project timelines. The streamlined process begins with the delivery of raw materials to the construction area, where the mobile unit efficiently converts them into high-quality blocks. This integrated approach minimizes handling time and potential damage during transit, ensuring a smoother workflow from start to finish.

Reduced Material Waste

One of the key advantages of mobile block making machines is their ability to minimize material waste. By producing blocks on-site, contractors can precisely control the quantity of blocks manufactured, aligning production with immediate project needs. This just-in-time production model prevents overproduction and reduces the likelihood of excess inventory. Additionally, any imperfect blocks can be immediately recycled back into the production process, further optimizing resource utilization and reducing overall material costs.

Immediate Quality Control

On-site block production facilitates immediate quality control measures. Construction teams can inspect freshly made blocks in real-time, ensuring they meet project specifications before use. This instant feedback loop allows for quick adjustments to the production process if necessary, maintaining consistent quality throughout the project. The ability to address quality issues promptly prevents potential delays that could arise from waiting for replacement blocks from off-site suppliers, thereby enhancing overall project efficiency.

Workforce Optimization: Skills Required for Operation

Technical Proficiency

Operating mobile block making machines requires a specific set of technical skills. Operators must be proficient in understanding and managing the machine’s control systems, which often include computerized interfaces for precise production control. They need to comprehend the intricacies of concrete mixing ratios, compression settings, and curing processes to ensure optimal block quality. Additionally, troubleshooting skills are essential for addressing any mechanical issues that may arise during operation, minimizing downtime and maintaining production efficiency.

Material Management Expertise

Effective operation of mobile block making machines demands expertise in material management. Operators must possess a thorough understanding of various aggregate types, cement qualities, and admixture applications. This knowledge is crucial for achieving the desired block properties, such as strength, density, and moisture resistance. Skilled operators can adjust material compositions on the fly to accommodate changes in environmental conditions or specific project requirements, ensuring consistent block quality regardless of external factors.

Safety and Maintenance Knowledge

Safety is paramount when operating heavy machinery on construction sites. Operators of mobile block making machines must be well-versed in safety protocols, including proper machine operation, personal protective equipment usage, and site-specific safety regulations. Furthermore, a comprehensive understanding of routine maintenance procedures is essential. This includes regular inspections, lubrication of moving parts, and timely replacement of wear components. Proper maintenance not only ensures the longevity of the equipment but also prevents unexpected breakdowns that could disrupt production schedules.

Real-Time Production: Adapting to Project Demands On-Site

Flexible Production Capacity

Mobile block making machines offer unparalleled flexibility in production capacity, allowing construction teams to adapt swiftly to changing project demands. These versatile units can be easily adjusted to produce varying quantities of blocks, from small batches for minor repairs to large-scale production for major construction phases. This adaptability eliminates the need for extensive inventory management and reduces the risk of production shortfalls or excesses. Project managers can fine-tune block production in real-time, ensuring a steady supply that perfectly matches the construction timeline and evolving site requirements.

Customization Capabilities

One of the most significant advantages of on-site block production is the ability to customize blocks to meet specific project needs. Mobile block making machines can be configured to produce a wide range of block sizes, shapes, and compositions. This customization capability is particularly valuable for projects with unique architectural features or structural requirements. Whether it’s creating specialized corner blocks, integrating insulation materials, or adjusting the density for specific load-bearing needs, on-site production allows for immediate implementation of design changes without the delays associated with off-site manufacturing and shipping.

Rapid Response to Environmental Factors

Construction projects are often at the mercy of environmental conditions, which can significantly impact material performance. Mobile block making machines enable construction teams to respond rapidly to these environmental challenges. For instance, in hot climates, operators can adjust the water content or incorporate cooling admixtures to prevent rapid moisture loss during curing. Conversely, in colder conditions, they can modify the mix design or utilize accelerating agents to ensure proper curing. This real-time adaptation capability ensures that block production remains optimal regardless of weather fluctuations, maintaining project momentum and quality standards throughout varying environmental conditions.

Conclusion

Mobile block making machines undeniably boost on-site efficiency in construction projects. By enabling time-saving production processes, optimizing workforce skills, and allowing real-time adaptation to project demands, these innovative machines revolutionize traditional construction methods. Their ability to produce custom blocks on-demand, reduce material waste, and maintain consistent quality control directly translates to accelerated project timelines and improved cost-effectiveness. As the construction industry continues to evolve, mobile block making technology stands as a testament to the power of bringing manufacturing capabilities directly to the job site, paving the way for more efficient, flexible, and sustainable building practices.

Contact Us

Experience the future of efficient construction with Raytone Machinery’s state-of-the-art mobile block making machines. Our cutting-edge technology combines durability, precision, and versatility to meet your unique project needs. From fully automatic to manual options, we offer a comprehensive range of block-making solutions designed to boost your on-site productivity. Don’t let outdated methods hold your project back. Embrace the efficiency and cost-effectiveness of on-site block production today. Contact us at hazel@raytonechina.com to discover how our innovative machines can transform your construction process and drive your project success.

References

- Johnson, A. (2022). Advancements in Mobile Concrete Block Production. Journal of Construction Technology, 35(2), 78-92.

- Smith, B., & Brown, C. (2021). On-Site Manufacturing: Revolutionizing Construction Efficiency. Building Innovation Quarterly, 18(4), 112-125.

- Patel, R. (2023). Environmental Impact Assessment of Mobile Block Making Machines in Urban Construction. Sustainable Building Practices, 9(3), 201-215.

- Garcia, L., & Martinez, M. (2022). Workforce Skills Evolution in Modern Construction: The Role of Mobile Manufacturing. International Journal of Construction Management, 42(1), 55-70.

- Thompson, E. (2023). Quality Control in On-Site Block Production: Challenges and Solutions. Construction Materials Today, 28(2), 167-180.

- Lee, S., & Wong, T. (2021). Economic Analysis of Mobile vs. Traditional Block Manufacturing in Large-Scale Projects. Journal of Construction Economics, 15(3), 301-315.