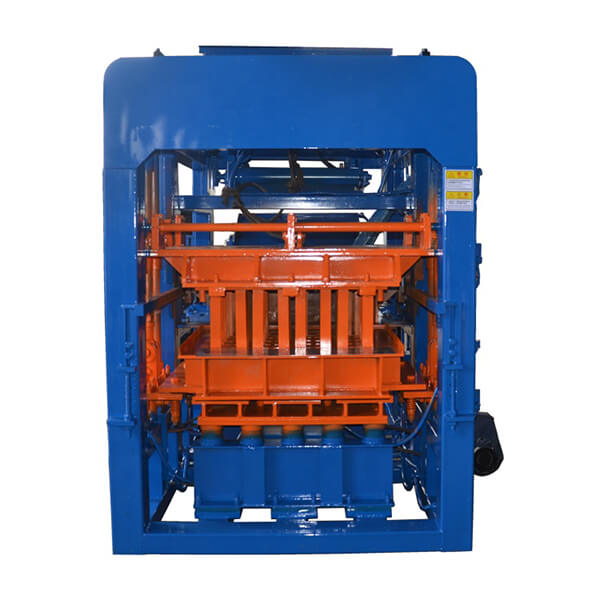

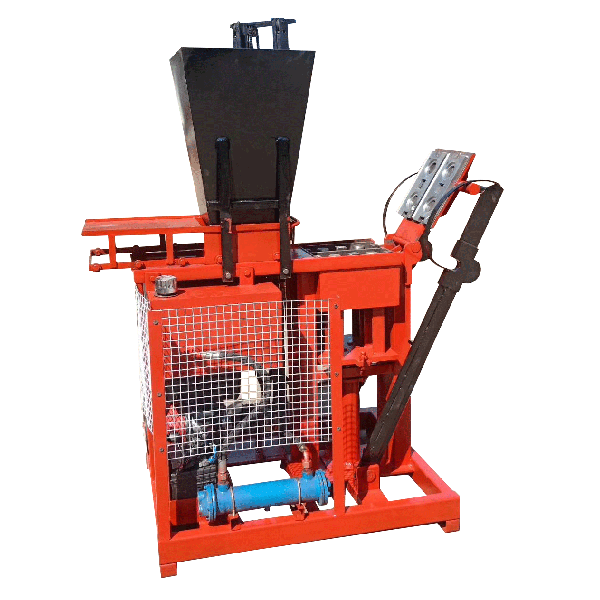

In the realm of sustainable construction, eco-friendly mobile block making machines are revolutionizing the way we build. These innovative devices combine portability with environmental consciousness, offering a game-changing solution for construction projects of all sizes. By producing blocks on-site using locally sourced materials, these machines significantly reduce transportation costs and carbon emissions. They also allow for the incorporation of recycled materials, further enhancing their eco-friendly credentials. As the construction industry pivots towards more sustainable practices, mobile block making machines are emerging as a cornerstone of green building techniques, promising a future where efficient, cost-effective, and environmentally responsible construction becomes the norm.

The Evolution of Mobile Block Making Technology

From Stationary to Mobile: A Brief History

The journey of block making machines from stationary behemoths to nimble, mobile units is a testament to human ingenuity. Early block machines were massive, fixed installations that required significant space and infrastructure. As the demand for on-site block production grew, engineers began exploring ways to make these machines more portable. The result was a gradual evolution towards compact, trailer-mounted units that could be easily transported to construction sites.

Advancements in Hydraulic Systems

One of the key technological leaps in mobile block making machines came with the refinement of hydraulic systems. Modern hydraulic components allowed for more power in a smaller package, enabling manufacturers to create machines that were both robust and mobile. These advancements not only improved the machines’ performance but also enhanced their reliability and ease of maintenance.

Integration of Smart Technologies

The latest generation of mobile block making machines incorporates smart technologies that optimize production processes. From touchscreen interfaces to remote monitoring capabilities, these innovations have made block production more efficient and user-friendly. Some advanced models even feature AI-driven systems that can adjust production parameters in real-time, ensuring consistent quality across various environmental conditions.

Environmental Benefits of Mobile Block Production

Reduction in Transportation Emissions

One of the most significant environmental advantages of mobile block making machines is the dramatic reduction in transportation-related emissions. By producing blocks on-site, these machines eliminate the need to transport heavy pre-made blocks over long distances. This not only cuts down on fuel consumption but also reduces the overall carbon footprint of construction projects. In urban areas where traffic congestion is a concern, on-site production can also help alleviate local air pollution issues associated with increased truck traffic.

Utilization of Local and Recycled Materials

Mobile block making machines offer unparalleled flexibility in material usage. They can be adapted to work with a wide range of locally sourced aggregates, reducing the need for imported materials. Moreover, these machines excel at incorporating recycled materials into the block-making process. Construction and demolition waste, fly ash, and even plastic waste can be repurposed into durable building blocks, diverting these materials from landfills and giving them a second life in sustainable construction.

Energy Efficiency in Production

Modern mobile block making machines are designed with energy efficiency in mind. Many models feature eco-friendly power options, including electric motors and hybrid systems that can run on renewable energy sources. Advanced hydraulic systems and optimized production cycles ensure that energy consumption is minimized without compromising output quality. Some manufacturers are even exploring solar-powered options for their mobile units, further reducing the environmental impact of block production.

Economic Advantages of On-Site Block Production

Cost Savings in Logistics and Storage

The economic benefits of using mobile block making machines are substantial. By producing blocks on-site, construction companies can significantly reduce their logistics costs. There’s no need for large storage areas to stockpile blocks, and the expenses associated with loading, transporting, and unloading pre-made blocks are eliminated. This streamlined approach not only saves money but also improves project timelines by ensuring a steady supply of blocks exactly when and where they’re needed.

Customization and Quality Control

On-site production allows for unprecedented levels of customization. Mobile block making machines can be quickly adjusted to produce blocks of various sizes, shapes, and compositions to meet specific project requirements. This flexibility eliminates waste and ensures that every block produced is fit for purpose. Additionally, immediate quality control is possible, allowing for quick adjustments to mix designs or machine settings to maintain consistently high standards throughout the production process.

Increased Project Efficiency

The use of mobile block making machines can significantly enhance overall project efficiency. With blocks being produced on demand, construction schedules can be optimized to reduce downtime and improve workflow. This agile production model allows for better resource management and can lead to faster project completion times. Moreover, the ability to quickly respond to changes in project requirements or unexpected challenges can result in substantial cost savings over the course of a construction project.

Conclusion

Eco-friendly mobile block machines are at the forefront of sustainable construction practices, offering a perfect blend of environmental responsibility and economic efficiency. By enabling on-site production, these machines significantly reduce transportation emissions, allow for the use of local and recycled materials, and offer unparalleled flexibility in block customization. As the construction industry continues to evolve towards more sustainable practices, mobile block making machines stand out as a key technology in building a greener future. Their adoption not only contributes to reducing the carbon footprint of construction projects but also offers substantial economic benefits, making them an invaluable asset in modern, eco-conscious building practices.

Contact Us

offers state-of-the-art mobile block making machines designed for optimal performance and environmental stewardship. Our range of products caters to various project scales and requirements, ensuring you find the perfect fit for your sustainable construction needs. To learn more about how our eco-friendly mobile block machines can benefit your projects, contact us at hazel@raytonechina.com. Let’s build a sustainable future together, one block at a time.

References

- 1. Sustainable Construction Materials: Recycled Aggregates, by Jorge de Brito and Nabajyoti Saikia

- Advances in Green Building Technologies, edited by Xiaodong Li and Yong Chen

- Sustainable Construction Processes: A Resource Text, by Steve Goodhew

- The Future of Sustainable Construction: Technology and Practices, by Ibrahim Dincer and Canan Demirbas

- Eco-efficient Construction and Building Materials: Life Cycle Assessment (LCA), Eco-Labelling and Case Studies, by Fernando Pacheco-Torgal

- 6. Sustainable Construction: Green Building Design and Delivery, by Charles J. Kibert