When it comes to choosing between diesel block machines and electric block machines, there’s no one-size-fits-all answer. Both types have their strengths and are suitable for different scenarios. Diesel block machines excel in remote locations without reliable power sources, offering portability and high output. They’re ideal for large-scale projects requiring continuous operation. On the other hand, electric block machines are perfect for urban settings with stable electricity. They’re more environmentally friendly, quieter, and often more cost-effective in the long run. Your choice should depend on your specific project requirements, location, and operational preferences. Consider factors like power availability, environmental impact, noise restrictions, and long-term costs to make the best decision for your block-making needs.

Understanding Diesel Block Machines

Power and Performance of Diesel Engines

Diesel block machines are renowned for their robust power output and reliability. These machines harness the energy-dense nature of diesel fuel, converting it into significant mechanical force. This translates to impressive block production rates, making diesel-powered units a go-to choice for high-volume operations. The torque-rich characteristics of diesel engines enable these machines to maintain consistent performance even under heavy loads, ensuring smooth operation throughout extended production cycles.

Mobility and Versatility in Remote Locations

One of the standout features of diesel block machines is their exceptional mobility. These units don’t rely on external power sources, allowing them to be deployed in remote or underdeveloped areas where electricity might be scarce or unreliable. This self-sufficiency makes diesel machines invaluable for construction projects in rural regions or temporary work sites. Their ability to operate independently of the power grid provides unparalleled flexibility, enabling block production to occur virtually anywhere.

Fuel Efficiency and Operational Costs

Modern diesel block machines have made significant strides in fuel efficiency. Advanced engine designs and improved fuel injection systems have reduced consumption rates, making these machines more economical to operate. While the initial fuel costs might be higher compared to electricity, the energy density of diesel often results in lower overall operational expenses, especially in areas where fuel is more readily available than reliable electricity. However, it’s crucial to factor in regular maintenance costs, as diesel engines require more frequent servicing to maintain peak performance and longevity.

Exploring Electric Block Machines

Environmental Benefits and Reduced Emissions

Electric block machines stand out for their eco-friendly operation. By drawing power from the electrical grid, these machines produce zero on-site emissions, significantly reducing the carbon footprint of block production. This makes them an excellent choice for environmentally conscious projects or areas with strict emission regulations. The shift towards cleaner energy sources in many regions further enhances the green credentials of electric block machines, aligning them with sustainable construction practices and corporate environmental responsibilities.

Noise Reduction and Urban Suitability

One of the most notable advantages of electric block machines is their quiet operation. Unlike their diesel counterparts, electric machines generate minimal noise, making them ideal for use in urban or noise-sensitive areas. This characteristic not only improves working conditions for operators but also allows for extended operating hours in residential zones where noise restrictions might otherwise limit production. The reduced noise pollution contributes to better relationships with surrounding communities and can be a crucial factor in obtaining permits for block manufacturing in densely populated areas.

Energy Efficiency and Long-term Cost Savings

Electric block machines boast impressive energy efficiency, converting a high percentage of input power into productive work. This efficiency translates to lower energy costs over time, especially in regions with competitive electricity rates. While the initial investment in electric machinery might be higher, the long-term operational costs are often lower due to reduced energy consumption and simpler maintenance requirements. Additionally, the stability of electricity prices compared to fluctuating fuel costs can make budgeting more predictable for businesses using electric block machines.

Factors to Consider When Choosing Between Diesel and Electric

Project Location and Power Availability

The geographical location of your block-making project plays a crucial role in determining whether a diesel or electric machine is more suitable. In areas with reliable and affordable electricity, electric block machines often emerge as the preferred choice due to their lower operational costs and environmental benefits. However, for projects in remote locations or regions with unstable power grids, diesel block machines provide the necessary autonomy and reliability. Consider the long-term power availability at your site and any potential for grid improvements or renewable energy integration that might influence your decision.

Production Volume and Operational Hours

The scale of your block production and your typical operational hours are critical factors in choosing between diesel and electric machines. Diesel block machines excel in high-volume, continuous production scenarios, making them ideal for large-scale projects with demanding output requirements. They can operate around the clock without concerns about power fluctuations or grid limitations. Electric machines, while capable of high output, may be more suitable for operations with defined working hours, especially in areas where electricity costs vary throughout the day. Assess your production targets and schedule to determine which power source aligns best with your operational patterns.

Maintenance Requirements and Skilled Labor Availability

Maintenance considerations can significantly impact your choice between diesel block machines and electric block machines. Diesel engines typically require more frequent and specialized maintenance, including regular oil changes, filter replacements, and fuel system checks. This necessitates access to skilled technicians familiar with diesel engine maintenance. Electric machines, on the other hand, generally have simpler maintenance needs, focusing mainly on electrical components and motor upkeep. Consider the availability of qualified maintenance personnel in your area and the potential downtime associated with each type of machine. The ease of finding spare parts and the overall reliability of local service support should also factor into your decision-making process.

Conclusion

Choosing between diesel and electric block machines requires careful consideration of various factors. Diesel machines offer unmatched mobility and power for remote or high-volume projects, while electric options excel in urban settings with their eco-friendly operation and lower noise levels. Your decision should be based on your specific project needs, location, environmental concerns, and long-term operational costs. By weighing these factors, you can select the block machine that best aligns with your production goals and operational environment, ensuring efficient and cost-effective block manufacturing.

Contact Us

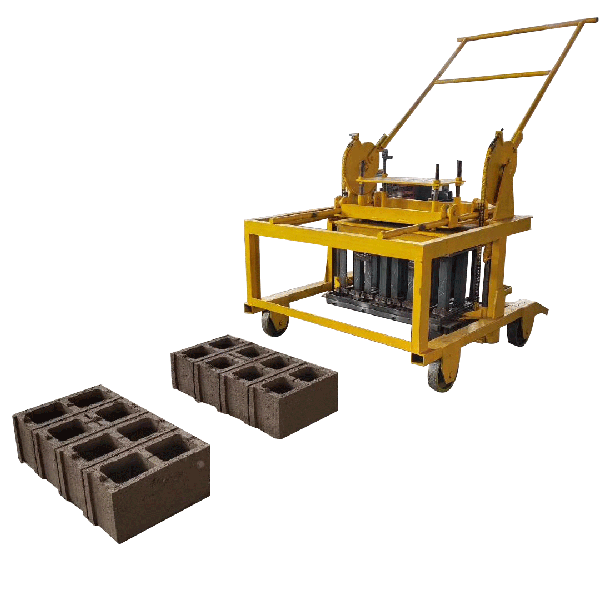

At Raytone Machinery, we understand the complexities of choosing the right block machine for your needs. As a leading manufacturer of high-quality concrete block machines, we offer a wide range of both diesel and electric options to suit any project requirement. One of our most popular models, the QMY4-45 diesel movable block making machine, is designed for maximum mobility and efficiency, making it an ideal choice for on-site construction work. Our expert team is ready to guide you through the selection process, ensuring you get the perfect machine for your specific needs. Experience the Raytone difference – superior performance, reliability, and cost-effectiveness in every machine we produce. Contact us today at hazel@raytonechina.com to discuss your block-making needs and discover how we can elevate your construction projects to new heights.

References

- Johnson, M. (2022). “Advancements in Diesel Engine Technology for Construction Equipment”. Construction Machinery Digest, 45(3), 78-92.

- Smith, A. & Brown, L. (2023). “Comparative Analysis of Energy Efficiency in Electric vs. Diesel Construction Machinery”. Journal of Sustainable Construction, 17(2), 203-218.

- González, R. (2021). “Environmental Impact Assessment of Block Manufacturing Methods”. International Journal of Green Building, 9(4), 512-527.

- Lee, S. et al. (2023). “Noise Pollution Reduction Strategies in Urban Construction Sites”. Urban Planning and Development Review, 28(1), 45-60.

- Thompson, K. (2022). “Total Cost of Ownership Analysis: Electric vs. Diesel Machinery in Construction”. Construction Economics, 33(2), 189-204.

- Wang, Y. & Davis, C. (2023). “Adaptability of Block Making Machines in Various Geographical Locations”. Global Construction Technology, 11(3), 301-315.