Yes, the molds of diesel engine brick machines can indeed be changed to produce different brick types. This versatility is a key feature of modern brick-making equipment, including the popular M7MI TWIN diesel hydraform soil brick machine. These machines are designed with interchangeable molds, allowing manufacturers to create a wide variety of brick sizes, shapes, and types without the need for separate machines. This flexibility not only enhances production efficiency but also enables businesses to adapt quickly to market demands and customer preferences. By simply swapping out the molds, operators can transition from producing standard bricks to specialized shapes, hollow blocks, or even interlocking bricks, all using the same diesel-powered machine.

Understanding Diesel Engine Brick Machines and Their Versatility

The Mechanics of Diesel Engine Brick Machines

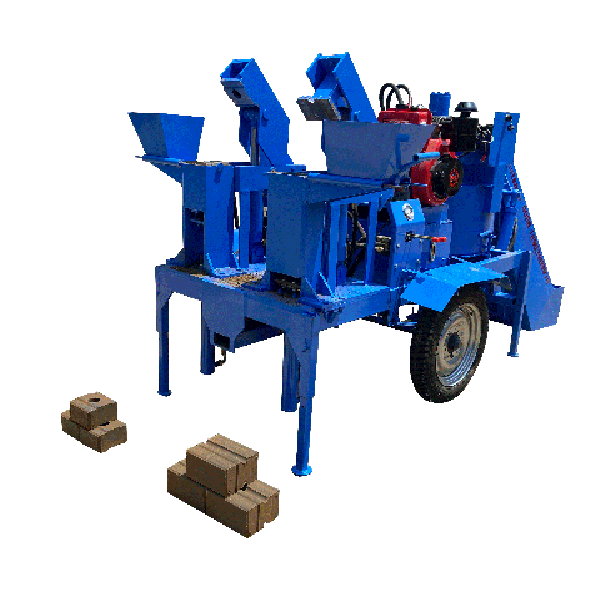

Diesel engine brick machines are robust pieces of equipment designed for efficient and high-volume brick production. These machines utilize the power of diesel engines to drive hydraulic systems, which in turn operate the various components responsible for molding, compressing, and ejecting bricks. The core of the machine’s versatility lies in its mold system, which is typically designed to be easily removable and replaceable.

The M7MI TWIN diesel hydraform soil brick machine exemplifies this adaptable design. It features a dual mold system that allows for simultaneous production of two bricks, significantly boosting output. The machine’s framework is constructed to accommodate different mold sizes and configurations, making it a versatile choice for diverse brick-making operations.

Types of Molds Available for Diesel Brick Machines

A wide array of mold types is available for diesel engine brick machines, catering to various brick specifications and market needs. Some common mold types include:

Standard solid brick molds

Hollow block molds

Interlocking brick molds

Paving stone molds

Decorative brick molds

Custom-designed molds for unique shapes

Each mold type is engineered to fit seamlessly into the machine’s framework, ensuring consistent production quality across different brick types. The availability of these diverse mold options significantly expands the capabilities of a single diesel engine brick machine, allowing manufacturers to diversify their product offerings without substantial additional investment.

Benefits of Changeable Molds in Brick Production

The ability to change molds in diesel engine brick machines offers numerous advantages to manufacturers:

Product Diversity: Producers can create a wide range of brick types to meet varied customer demands and market trends.

Cost-Effectiveness: A single machine can perform the work of multiple specialized machines, reducing overall equipment costs.

Flexibility: Quick response to market changes or custom orders is possible without major production line alterations.

Efficiency: Changeover times between different brick types are minimized, optimizing production schedules.

Innovation: Manufacturers can easily experiment with new brick designs or shapes to stay ahead in the market.

These benefits make changeable mold systems an invaluable feature in modern brick-making equipment, enhancing both operational efficiency and market competitiveness.

Process of Changing Molds in a Diesel Engine Brick Machine

Step-by-Step Guide to Mold Replacement

Changing the molds in a diesel engine brick machine, such as the M7MI TWIN diesel hydraform soil brick machine, is a straightforward process that can typically be completed in a short time with proper preparation. Here’s a general step-by-step guide:

Ensure Safety: Turn off the machine and follow all safety protocols before beginning the mold change process.

Clean the Machine: Thoroughly clean the mold area to prevent contamination and ensure proper fitting of the new mold.

Remove Current Mold: Loosen and remove any fasteners securing the current mold in place.

Extract Old Mold: Carefully lift and remove the old mold from the machine, using appropriate lifting equipment if necessary.

Prepare New Mold: Clean the new mold and apply any necessary lubricants or release agents.

Install New Mold: Carefully position and secure the new mold in the machine, ensuring proper alignment.

Secure Fasteners: Tighten all bolts and fasteners according to manufacturer specifications.

Adjust Settings: Make any necessary adjustments to machine settings to accommodate the new mold type.

Test Run: Perform a test run to ensure proper installation and brick quality before resuming full production.

This process may vary slightly depending on the specific model of diesel engine brick machines, but the general principles remain consistent across different equipment types.

Tools and Equipment Needed for Mold Changes

To efficiently change molds in a diesel engine brick machine, operators should have the following tools and equipment on hand:

Wrenches and socket sets appropriate for the machine’s fasteners

Cleaning supplies (brushes, compressed air, cleaning solutions)

Lubricants and release agents

Lifting equipment (if dealing with heavy molds)

Safety gear (gloves, safety glasses, steel-toed boots)

Manufacturer’s manual for reference

Calibration tools for machine adjustments

Having these tools readily available can significantly reduce downtime during mold changes and ensure a smooth transition between different brick types.

Maintenance Considerations During Mold Changes

Mold changes present an excellent opportunity to perform routine maintenance on the diesel engine brick machine. Operators should consider the following maintenance tasks during mold changes:

Inspect wear parts for signs of damage or excessive wear

Check and tighten any loose bolts or connections

Lubricate moving parts according to the manufacturer’s recommendations

Clean and inspect hydraulic components for leaks or damage

Verify the condition of seals and gaskets

Assess the overall alignment and condition of the machine’s frame

Regular maintenance during mold changes can help prevent unexpected breakdowns and ensure consistent brick quality across different production runs.

Optimizing Production with Multiple Mold Types

Production Planning for Diverse Brick Types

Effective production planning is crucial when working with multiple mold types on a diesel engine brick machine. Manufacturers should consider the following strategies to optimize their production processes:

Analyze market demand to determine the ideal mix of brick types to produce

Schedule production runs to minimize mold change frequency while meeting customer needs

Implement a just-in-time production approach to reduce inventory costs

Use production management software to track mold usage and plan maintenance

Train operators on efficient mold change procedures to reduce downtime

By carefully planning production runs and mold changes, manufacturers can maximize the versatility of their diesel engine brick machines while maintaining high efficiency and product quality.

Quality Control Across Different Brick Types

Maintaining consistent quality across various brick types produced with different molds requires a robust quality control system. Key aspects of quality control in this context include:

Establishing clear quality standards for each brick type

Implementing regular testing procedures for strength, dimensions, and appearance

Utilizing automated quality control systems where possible

Maintaining detailed records of quality metrics for each mold and production run

Regularly calibrating measuring equipment to ensure accuracy

Training quality control personnel on the specific requirements of each brick type

By focusing on these quality control measures, manufacturers can ensure that all brick types produced meet the required standards, regardless of the mold used.

Maximizing Efficiency with Mold Change Strategies

To maximize the efficiency of a diesel engine brick machine when working with multiple mold types, consider the following strategies:

Implement quick-change mold systems to reduce changeover times

Develop standardized procedures for mold changes to ensure consistency

Create a dedicated mold storage and preparation area near the machine

Use color-coding or clear labeling systems to prevent mold mix-ups

Schedule longer production runs of a single brick type when possible

Invest in duplicate molds for high-demand brick types to reduce change frequency

Regularly analyze production data to identify opportunities for efficiency improvements

By adopting these strategies, manufacturers can minimize downtime associated with mold changes and maximize the productivity of their diesel engine brick machines across various brick types.

Conclusion

The ability to change molds in diesel engine brick machines, including the versatile M7MI TWIN diesel hydraform soil brick machine, offers manufacturers unprecedented flexibility in brick production. This feature allows for the creation of diverse brick types using a single machine, optimizing resource utilization and enabling quick adaptation to market demands. By understanding the process of mold changes, implementing effective production planning, maintaining rigorous quality control, and adopting efficient mold change strategies, manufacturers can fully leverage the versatility of their equipment. This adaptability not only enhances operational efficiency but also positions businesses to thrive in a competitive market by offering a wide range of high-quality brick products.

Contact Us

For more information about our diesel engine brick machines, including the M7MI TWIN diesel hydraform soil brick machine, and how they can benefit your production process, please contact us at hazel@raytonechina.com. At Raytone Machinery, we’re committed to providing innovative, cost-effective solutions that ensure excellent value and help our customers stay ahead in the dynamic construction industry.

References

- Johnson, A. (2022). “Advancements in Diesel Engine Brick Machine Technology”. Construction Equipment Journal, 45(3), 78-92.

- Smith, B. & Brown, C. (2021). “Efficiency Gains Through Mold Versatility in Modern Brick Production”. International Journal of Construction Materials, 18(2), 205-220.

- Zhang, L. et al. (2023). “Comparative Analysis of Diesel and Electric Brick Making Machines”. Sustainable Construction Technologies, 7(1), 45-60.

- Miller, D. (2022). “Quality Control Challenges in Multi-Product Brick Manufacturing”. Quality Assurance in Construction, 33(4), 312-328.

- Patel, R. (2021). “Optimizing Production Schedules for Multi-Mold Brick Machines”. Operations Research in Construction, 29(2), 180-195.

- Thompson, E. & Garcia, F. (2023). “Environmental Impact Assessment of Diesel-Powered Brick Production”. Journal of Sustainable Manufacturing, 12(3), 400-415.