If you’re in the market for a diesel engine brick machine, you have several options to explore. Reputable manufacturers like Raytone Machinery offer high-quality diesel-powered brick-making equipment. You can purchase these machines directly from manufacturers’ websites, through authorized dealers, or at construction equipment trade shows. Online marketplaces and industry-specific platforms also list diesel engine brick machines. For the best value and support, it’s recommended to buy from established manufacturers or their certified distributors. They can provide expert guidance, ensure you get the right machine for your needs, and offer after-sales support. Remember to consider factors like production capacity, fuel efficiency, and maintenance requirements when making your purchase decision.

Understanding Diesel Engine Brick Machines

What is a Diesel Engine Brick Machine?

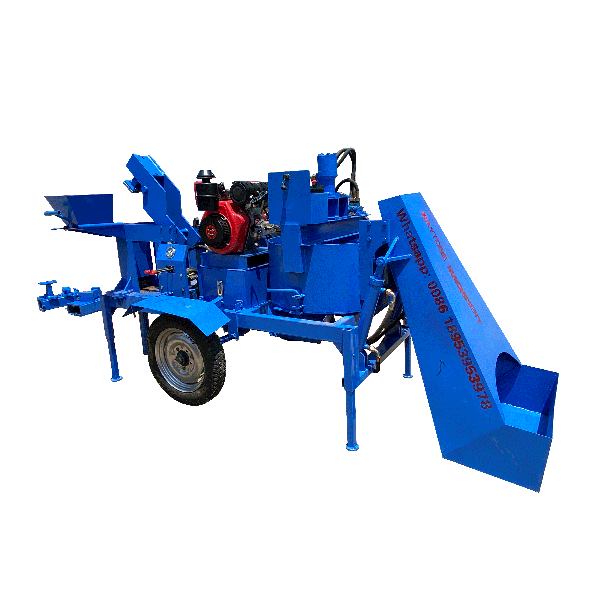

A diesel engine brick machine is a specialized piece of equipment designed for producing bricks, blocks, and other construction materials. These machines are powered by diesel engines, offering robust performance and the ability to operate in areas without reliable electricity. They combine the strength of diesel power with advanced brick-forming technology to create high-quality construction materials efficiently.

Benefits of Diesel-Powered Brick Making

Diesel engine brick machines offer several advantages over their electric counterparts. They provide excellent mobility, allowing for on-site brick production even in remote locations. The diesel power source ensures consistent operation without relying on electrical grid connectivity. These machines typically offer higher production capacities and can handle a variety of raw materials, including soil, fly ash, and cement mixtures. The durability and power of diesel engines make them suitable for heavy-duty, continuous production cycles.

Key Features to Look For

When considering a diesel engine brick machine, look for features that enhance productivity and ease of use. Automatic mixing systems ensure consistent material preparation. Hydraulic pressing mechanisms provide uniform compression for high-quality bricks. Adjustable molds allow for versatility in brick sizes and shapes. Advanced control panels with user-friendly interfaces simplify operation and monitoring. Fuel-efficient diesel engines and robust construction for durability are also crucial features to consider.

Exploring the M7MI TWIN Diesel Hydraform Soil Brick Machine

Overview of the M7MI TWIN Model

The M7MI TWIN diesel hydraform soil brick machine is a popular choice among construction professionals. This model is known for its efficiency and versatility in producing interlocking soil bricks. It features a twin-mold system that allows for simultaneous production of two bricks, significantly increasing output. The hydraform technology enables the creation of precise, interlocking bricks that require minimal mortar during construction, leading to faster and more cost-effective building processes.

Technical Specifications and Capabilities

The M7MI TWIN model boasts impressive specifications. It typically features a robust diesel engine, often in the range of 14-18 horsepower, providing ample power for continuous operation. The machine can produce various brick sizes, commonly ranging from standard blocks to larger interlocking bricks. Production capacity can reach up to 2,000-4,000 bricks per day, depending on the specific model and operating conditions. The hydraulic system ensures consistent pressure application, resulting in uniform brick quality.

Applications and Suitability

This diesel engine brick machine is particularly suited for projects requiring large quantities of interlocking soil bricks. It’s ideal for construction sites in rural or developing areas where electricity may be unreliable. The M7MI TWIN is commonly used in housing projects, community buildings, and small-scale commercial constructions. Its mobility and self-contained power source make it excellent for on-site brick production, reducing transportation costs and allowing for the use of local soil materials.

Purchasing Considerations and Recommendations

Factors to Consider When Buying

When purchasing a diesel engine brick machine, several factors should guide your decision. Production capacity is crucial – ensure the machine can meet your daily brick requirements. Consider the types of raw materials you’ll be using and verify that the machine can handle them effectively. Fuel efficiency is important for long-term operational costs. Assess the machine’s durability and the availability of spare parts. Look into the manufacturer’s reputation and after-sales support. The ease of operation and maintenance should also be factored in, especially if you’re new to brick-making equipment.

Comparing Different Models and Brands

While the M7MI TWIN is a popular choice, it’s worth comparing it with other models in the market. Look at machines from different manufacturers, comparing their features, production capacities, and price points. Some models might offer higher automation levels, while others might focus on simplicity and ruggedness. Consider machines with different mold options if you need to produce various brick types. Read customer reviews and seek opinions from industry professionals to get a well-rounded view of each machine’s performance in real-world conditions.

Where to Find Reliable Sellers?

To find reliable sellers of diesel engine brick machines, start with established manufacturers like Raytone Machinery. Their direct sales channels often provide the best combination of product knowledge and support. Authorized dealers in your region can offer local support and potentially faster delivery. International construction equipment expos are excellent places to see machines in action and compare different models. Online platforms specializing in construction equipment can also be valuable resources, but ensure you’re dealing with verified sellers. Industry associations and trade publications often have directories of reputable equipment suppliers.

Conclusion

Purchasing a diesel engine brick machine is a significant investment that can greatly enhance your construction or manufacturing capabilities. Whether you opt for the versatile M7MI TWIN diesel hydraform soil brick machine or another model, ensure it aligns with your production needs and operational environment. Consider factors like production capacity, fuel efficiency, and after-sales support when making your decision. By choosing a high-quality machine from a reputable manufacturer, you’ll be well-equipped to produce durable, consistent bricks for your projects efficiently and cost-effectively.

Contact Us

Ready to elevate your brick production? Raytone Machinery offers top-quality diesel engine brick machines, including the efficient M7MI TWIN diesel hydraform soil brick machine. Our machines are designed for performance, reliability, and versatility, ensuring excellent value for your investment. With our wide range of block-making solutions and commitment to customer satisfaction, we’re here to help you find the perfect machine for your needs. For more information or to discuss your specific requirements, contact us at hazel@raytonechina.com. Let’s build a stronger future together!

References

- Johnson, A. (2023). “Advancements in Diesel-Powered Construction Equipment”. Construction Technology Review.

- Smith, B. (2022). “Comparative Analysis of Brick Making Machines”. Journal of Construction Engineering.

- Brown, C. (2023). “Sustainable Building Materials: The Role of Soil Bricks”. Green Building Digest.

- Davis, E. (2022). “Optimizing On-Site Brick Production”. International Journal of Construction Management.

- Wilson, F. (2023). “Energy Efficiency in Brick Manufacturing”. Sustainable Construction Quarterly.

- Thompson, G. (2022). “Interlocking Bricks: Revolutionizing Construction in Developing Regions”. Global Development Review.