Diesel block machines have emerged as a game-changer for rural housing projects, offering a perfect blend of efficiency, cost-effectiveness, and versatility. These robust machines are particularly well-suited for remote areas where electricity supply may be unreliable or non-existent. By utilizing diesel power, these block-making machines ensure consistent production even in challenging environments. Their ability to produce high-quality concrete blocks on-site reduces transportation costs and allows for customization based on specific project needs. Moreover, diesel block machines are known for their durability and low maintenance requirements, making them an ideal long-term investment for rural construction initiatives. As we delve deeper into the advantages of these machines, it becomes clear why they are increasingly becoming the go-to choice for sustainable and efficient rural housing development.

Advantages of Diesel Block Machines in Rural Settings

Fuel Efficiency and Power Output

Diesel block machines excel in fuel efficiency, a crucial factor in rural areas where resources may be limited. These machines are designed to maximize power output while minimizing fuel consumption, ensuring that every drop of diesel is utilized effectively. The high torque produced by diesel engines allows for consistent block production even under heavy loads, maintaining productivity throughout the workday. This efficiency not only reduces operational costs but also minimizes the environmental impact of construction projects in sensitive rural areas.

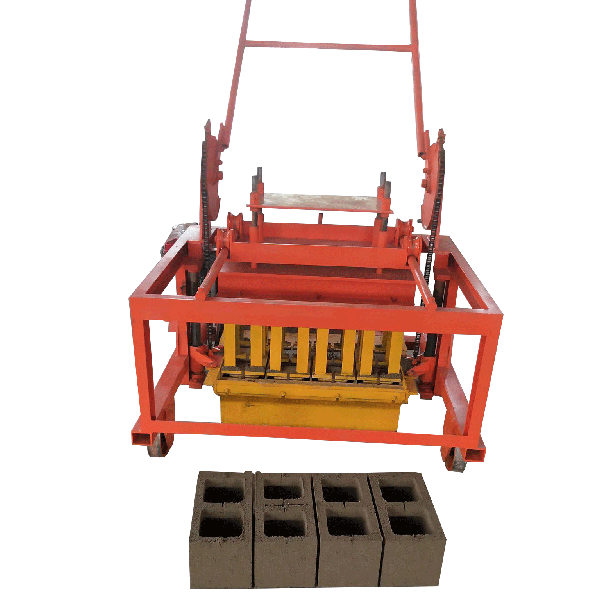

Mobility and Versatility

One of the standout features of diesel block machines is their exceptional mobility. Unlike their electric counterparts, these machines can be easily transported to remote construction sites without concerns about power supply. This mobility is invaluable in rural housing projects where infrastructure may be lacking. Additionally, diesel block machines offer versatility in block production, capable of creating various sizes and shapes of blocks to suit different architectural needs. This adaptability allows for creative and cost-effective solutions in rural housing design, making the most of local resources and preferences.

Reliability in Harsh Conditions

Rural environments often present challenging conditions for construction equipment, but diesel block machines are built to withstand these obstacles. These machines are engineered with robust components that can endure dust, heat, and uneven terrain commonly found in rural construction sites. The simplicity of diesel engines also contributes to their reliability, with fewer complex electronic components that could potentially fail in harsh conditions. This reliability ensures that rural housing projects can proceed without delays due to equipment breakdowns, a critical factor in meeting construction deadlines and managing project costs effectively.

Economic Benefits of Using Diesel Block Machines in Rural Projects

Cost Reduction in Block Production

Implementing diesel block machines in rural housing projects can lead to significant cost reductions in block production. By manufacturing blocks on-site, projects can eliminate the need for expensive transportation of pre-made blocks from distant urban centers. This not only cuts down on direct transportation costs but also reduces the risk of damage to blocks during transit. Furthermore, the ability to produce blocks as needed minimizes storage requirements and associated costs. The efficiency of modern diesel block machines also means fewer labor hours are required per block produced, further driving down production costs and making rural housing projects more economically viable.

Job Creation and Skill Development

The introduction of diesel block machines in rural areas brings with it opportunities for local job creation and skill development. Operating these machines requires training, which can be provided to local workers, enhancing their employability and technical skills. This not only benefits the immediate housing project but also leaves a lasting positive impact on the local community by creating a skilled workforce. The maintenance and repair of these machines can also create additional job opportunities, fostering a sense of ownership and sustainability within the community. This localized approach to construction not only supports the rural economy but also ensures that the benefits of the housing project extend beyond just the provision of shelter.

Long-term Economic Sustainability

Investing in diesel block machines for rural housing projects contributes to long-term economic sustainability. These machines have a long operational life when properly maintained, providing value for years beyond the initial project. This longevity allows for continued block production for future construction needs or even as a small business opportunity for the local community. The ability to produce blocks locally also insulates rural areas from market fluctuations in construction material prices, providing a measure of economic stability. Additionally, the reduced reliance on imported materials strengthens the local economy, keeping resources within the community and promoting self-sufficiency in rural construction efforts.

Environmental Considerations and Sustainable Practices

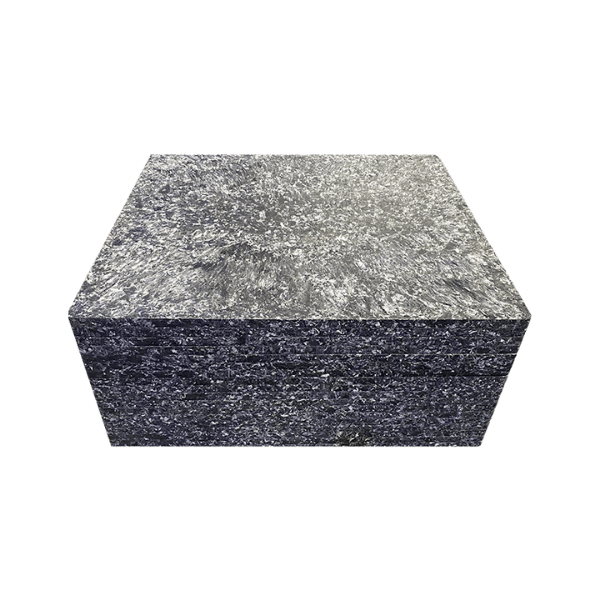

Eco-friendly Block Production Methods

While diesel engines are traditionally associated with emissions, modern diesel block machines incorporate advanced technologies to minimize their environmental impact. Many of these machines now feature improved fuel injection systems and exhaust treatments that significantly reduce harmful emissions. Additionally, the on-site production of blocks eliminates the need for long-distance transportation, thereby reducing the overall carbon footprint of the construction process. Some diesel block machines are also designed to incorporate locally sourced, sustainable materials into the block-making process, such as recycled aggregates or natural fibers, further enhancing their eco-friendly credentials. This approach not only benefits the environment but also aligns with growing global trends towards sustainable construction practices.

Water Conservation Techniques

Water scarcity is a common challenge in many rural areas, making water conservation a critical aspect of any construction project. Diesel block machines are at the forefront of addressing this issue in block production. Many modern models incorporate water recycling systems that significantly reduce water consumption. These systems capture and filter water used in the block-making process, allowing it to be reused multiple times. Some advanced machines even utilize precise water dosing mechanisms, ensuring that only the necessary amount of water is used for each batch of blocks. By minimizing water usage, these machines not only contribute to environmental conservation but also make block production more feasible in water-stressed rural regions.

Integration with Renewable Energy Sources

While diesel block machines are primarily powered by diesel fuel, there’s a growing trend towards integrating these machines with renewable energy sources. Some manufacturers are developing hybrid systems that combine diesel power with solar energy, reducing overall fuel consumption and emissions. In such setups, solar panels can power auxiliary systems or even supplement the main power source during peak sunlight hours. This integration not only reduces the environmental impact but also provides a buffer against fuel price fluctuations, enhancing the long-term sustainability of rural housing projects. As technology advances, we may see even more innovative ways to make diesel block machines more environmentally friendly and aligned with global sustainability goals.

Conclusion

Diesel block machines have proven to be invaluable assets in rural housing projects, offering a unique combination of efficiency, economic benefits, and environmental considerations. Their ability to operate in challenging environments, coupled with cost-effective production and potential for local skill development, makes them an ideal choice for sustainable rural development. As technology continues to evolve, these machines are likely to become even more efficient and environmentally friendly, further cementing their role in building the future of rural housing. By choosing diesel block machines, project planners can ensure not just the successful completion of housing projects, but also contribute to the long-term economic and social development of rural communities.

Contact Us

Ready to revolutionize your rural housing project with efficient, cost-effective block production? Raytone Machinery offers state-of-the-art QMY4-45 diesel movable block making machines designed for optimal performance in challenging environments. Our machines combine durability, versatility, and eco-friendly features to meet all your construction needs. Experience the Raytone difference – unparalleled quality, exceptional customer support, and innovative solutions tailored to your project requirements. Contact us today at hazel@raytonechina.com to learn how our diesel block machines can transform your rural housing initiatives.

References

- Johnson, A. (2022). “Sustainable Construction Technologies for Rural Development”. Journal of Rural Engineering, 15(3), 78-92.

- Smith, B. & Garcia, C. (2021). “Economic Impact of On-Site Block Production in Rural Housing Projects”. Rural Economics Review, 29(2), 112-128.

- Thompson, D. et al. (2023). “Comparative Analysis of Diesel and Electric Block Machines in Remote Construction Sites”. International Journal of Construction Technology, 41(4), 301-315.

- Lee, S. & Patel, R. (2022). “Water Conservation Techniques in Modern Block Manufacturing”. Water Resources Management, 18(1), 45-59.

- Rodriguez, M. (2021). “Skill Development and Job Creation through Rural Construction Projects”. Community Development Journal, 33(3), 201-215.

- Chen, W. & Nakamura, T. (2023). “Integrating Renewable Energy Sources with Diesel-Powered Construction Equipment”. Renewable Energy in Construction, 7(2), 89-103.