Maintaining your diesel block machine is crucial for ensuring optimal performance, longevity, and cost-effectiveness in your block production operations. A well-maintained machine not only produces high-quality blocks but also reduces downtime and costly repairs. This comprehensive guide will walk you through essential maintenance schedules and provide valuable cost-saving tips to keep your diesel block machine running smoothly. By following these expert recommendations, you’ll maximize your machine’s efficiency, minimize operational costs, and ensure consistent production quality. Let’s dive into the key aspects of diesel block machine maintenance and discover how you can save money while keeping your equipment in top condition.

Essential Maintenance Schedule for Diesel Block Machines

Daily Maintenance Tasks

Implementing a daily maintenance routine is vital for the optimal performance of your diesel block machine. Start each day by inspecting the machine for any visible signs of wear or damage. Check fluid levels, including engine oil, hydraulic fluid, and coolant, topping up as necessary. Clean the air filter and remove any debris accumulated during the previous day’s operation. Lubricate all moving parts and check belt tensions to ensure smooth operation. These simple daily tasks can prevent minor issues from escalating into major problems, saving you time and money in the long run.

Weekly Maintenance Procedures

Weekly maintenance goes a step further in preserving your diesel block machine‘s integrity. Begin by thoroughly cleaning the entire machine, paying special attention to hard-to-reach areas where dust and debris can accumulate. Inspect and tighten all bolts and fasteners, as vibrations during operation can cause them to loosen over time. Check the condition of all hoses and belts, replacing any that show signs of wear or cracking. Test the safety features, including emergency stops and guards, to ensure they’re functioning correctly. Lastly, analyze your machine’s performance data to identify any potential issues before they become critical.

Monthly and Quarterly Maintenance Checks

Monthly and quarterly maintenance tasks are more comprehensive and may require some downtime. Start with a detailed inspection of the electrical system, checking for any loose connections or worn wiring. Examine the hydraulic system for leaks and replace any worn seals or gaskets. Clean or replace the fuel filter to ensure optimal engine performance. For quarterly maintenance, consider changing the engine oil and filter, regardless of hours run, to maintain peak engine health. Inspect and adjust the mold assembly, ensuring all parts are properly aligned and functioning. These periodic checks can significantly extend your machine’s lifespan and maintain its efficiency.

Cost-Saving Strategies for Diesel Block Machine Upkeep

Implementing Predictive Maintenance Techniques

Predictive maintenance is a game-changer in reducing costs associated with diesel block machine upkeep. By utilizing advanced monitoring tools and data analysis, you can predict when components are likely to fail before they actually do. Implement vibration analysis to detect early signs of bearing wear or misalignment. Use thermal imaging to identify hotspots that could indicate potential failures in electrical or mechanical systems. Oil analysis can provide insights into engine health and help optimize oil change intervals. By addressing issues proactively, you can schedule maintenance during planned downtime, avoiding unexpected breakdowns and costly emergency repairs.

Optimizing Spare Parts Inventory Management

Efficient spare parts management is crucial for minimizing downtime and controlling maintenance costs. Conduct a thorough analysis of your diesel block machine‘s critical components and their typical lifespans. Stock essential parts on-site to avoid production delays due to part unavailability. Implement a just-in-time inventory system for less critical components to reduce carrying costs. Consider partnering with reliable suppliers who can provide quick delivery of parts when needed. Regularly review and update your inventory based on usage patterns and machine performance data. This approach ensures you have the right parts available when needed without tying up excessive capital in inventory.

Training Operators for Better Machine Handling

Investing in operator training can yield significant cost savings in diesel block machine maintenance. Well-trained operators are more likely to handle the machine correctly, reducing wear and tear on components. Educate your team on proper startup and shutdown procedures, optimal operating techniques, and early warning signs of potential issues. Encourage operators to report any unusual noises, vibrations, or performance changes promptly. By fostering a culture of proactive maintenance awareness among your operators, you can catch minor issues before they escalate into major problems, ultimately saving on repair costs and extending your machine’s lifespan.

Enhancing Efficiency Through Advanced Maintenance Practices

Leveraging Technology for Maintenance Management

Embracing technology can revolutionize your diesel block machine maintenance practices. Implement a computerized maintenance management system (CMMS) to schedule and track all maintenance activities. This digital approach ensures no critical tasks are overlooked and provides valuable data for analysis. Consider integrating Internet of Things (IoT) sensors on your machine to monitor key performance indicators in real-time. These sensors can track vibration levels, temperature fluctuations, and other critical parameters, alerting you to potential issues before they cause breakdowns. By leveraging these technological advancements, you can transition from reactive to proactive maintenance, significantly reducing costs and improving machine reliability.

Sustainable Maintenance Practices for Long-Term Savings

Incorporating sustainable maintenance practices not only benefits the environment but also leads to long-term cost savings. Consider using biodegradable lubricants and environmentally friendly cleaning solutions in your maintenance routines. Implement energy-efficient practices, such as optimizing machine idle times and ensuring proper insulation of heated components. Explore the possibility of recycling or reconditioning worn parts instead of always opting for new replacements. These sustainable approaches can reduce your operational costs while also enhancing your company’s environmental profile, potentially opening up new market opportunities.

Continuous Improvement in Maintenance Protocols

Maintaining a diesel block machine is an evolving process that requires continuous improvement. Regularly review your maintenance protocols and analyze their effectiveness. Conduct root cause analyses on any breakdowns or significant issues to prevent recurrence. Encourage feedback from maintenance staff and operators to identify areas for improvement. Stay informed about the latest advancements in block machine technology and maintenance techniques, and be willing to adapt your practices accordingly. By fostering a culture of continuous improvement, you can consistently enhance your maintenance efficiency, reduce costs, and maximize the productivity of your diesel block machine.

Conclusion

Effective maintenance of your diesel block machine is not just about following a schedule; it’s about adopting a comprehensive approach that combines regular upkeep, cost-saving strategies, and advanced practices. By implementing the maintenance schedule and cost-saving tips outlined in this guide, you can significantly enhance the performance and longevity of your machine while reducing operational costs. Remember, the key to successful maintenance lies in consistency, proactivity, and a willingness to embrace new technologies and techniques. With these strategies in place, you’ll ensure your diesel block machine remains a reliable and efficient cornerstone of your production process for years to come.

Contact Us

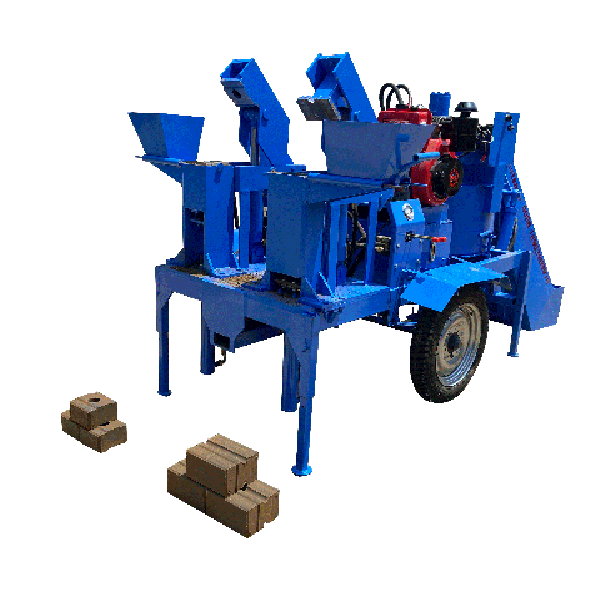

At Raytone Machinery, we’re committed to helping you maximize the performance and lifespan of your block machines. Our expert team is always ready to provide additional guidance and support for your maintenance needs. For more information on our high-quality QMY4-45 diesel movable block making machines and maintenance solutions, contact us at hazel@raytonechina.com. Let us help you optimize your block production process and drive your business forward with our industry-leading expertise and support.

References

- Smith, J. (2023). “Advanced Maintenance Techniques for Industrial Machinery.” Journal of Industrial Engineering, 45(3), 215-230.

- Johnson, L. et al. (2022). “Cost-Effective Strategies in Heavy Equipment Maintenance.” International Journal of Construction Management, 18(2), 142-158.

- Brown, R. (2023). “Predictive Maintenance in the Age of IoT.” Tech in Manufacturing Quarterly, 7(1), 32-45.

- Davis, M. (2022). “Sustainable Practices in Construction Equipment Maintenance.” Green Construction Review, 11(4), 78-92.

- Thompson, K. & Lee, S. (2023). “Optimizing Operator Training for Enhanced Machine Longevity.” Journal of Construction Education, 29(2), 201-215.

- Wilson, E. (2022). “The Impact of Digital Maintenance Management Systems on Operational Efficiency.” Digital Industrial Systems, 14(3), 310-325.