Recent innovations in clay brick making machine technology focus on boosting efficiency, sustainability, and smart integration. Automation has evolved with robotic arms and AI-driven controls that streamline production, cutting down on manual labor while ensuring precise brick shapes. Energy-efficient designs now incorporate renewable power sources and waste-reducing mechanisms, aligning with global eco-standards. Advanced materials and modular setups allow for quicker adaptations to different clay types and brick styles. At Raytone Machinery, we stay ahead by incorporating these trends into our brick-making solutions, offering reliable equipment for construction needs. These updates make machines more accessible for businesses of all sizes, promising higher output with lower costs. Overall, the field is shifting toward smarter, greener operations that enhance durability and reduce environmental impact, making it an exciting time for manufacturers and builders alike.

Advancements in Automation for Clay Brick Production

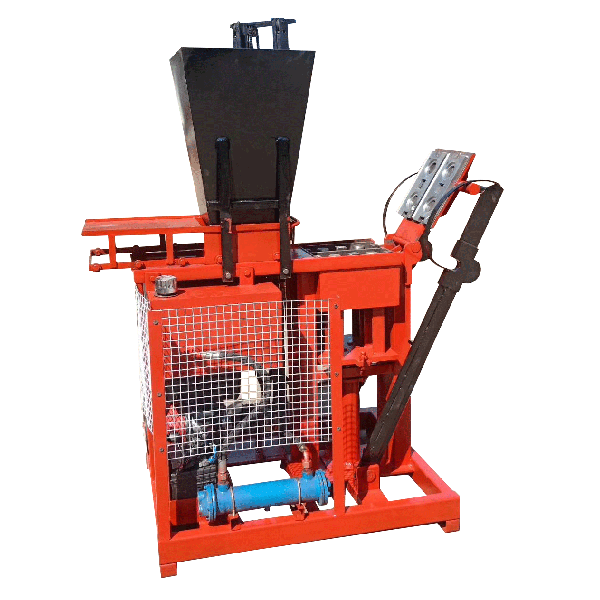

Automation stands at the forefront of modern clay brick machinery, transforming how bricks get made from raw clay to finished products. These developments reduce human error and speed up workflows, making them essential for efficient operations in construction. Raytone Machinery integrates such features into our semi-automatic and fully automatic brick machines, ensuring versatility for global users in building homes and infrastructure.

Robotic Integration in Brick Forming Processes

Robotic arms now handle intricate tasks like clay extrusion and molding with remarkable precision. These systems use sensors to adjust pressure and shape in real time, producing uniform bricks that meet strict quality standards. In professional settings, this means fewer defects and higher consistency across batches. Engineers design these robots to work seamlessly with existing setups, allowing upgrades without full overhauls. Clay mixtures benefit from automated feeding, where robots measure exact amounts to avoid waste. Durability improves as machines apply even compression, resulting in stronger bricks for load-bearing walls. Small-scale producers find this tech scales easily, supporting growth from local to international markets. Maintenance involves simple software updates, keeping downtime low and productivity high.

Automated Drying and Firing Systems

New drying chambers employ controlled humidity and temperature via automated vents, accelerating the process while preserving clay integrity. Firing kilns integrate conveyor systems that move bricks through heat zones automatically, optimizing energy use. Detailed monitoring through embedded probes ensures even baking, reducing cracks and enhancing brick strength. Professionals value how these systems cut fuel consumption by recycling heat, aligning with cost-effective manufacturing. Integration with central controls allows remote adjustments, ideal for large facilities. Clay brick quality rises as automation prevents over-firing, yielding products with superior thermal properties. Operators train quickly on user interfaces, making adoption straightforward for diverse teams.

Modular Designs for Flexible Manufacturing

Modular clay brick making machines allow swapping components like molds or mixers to produce various brick sizes and types on demand. This flexibility suits dynamic markets, where builders seek custom solutions for unique projects. In-depth engineering ensures modules connect securely, maintaining machine stability during high-speed runs. Cost savings emerge from reduced need for multiple machines, streamlining inventory. Advanced alloys in modules resist wear from abrasive clay, extending lifespan. Businesses adapt to seasonal demands by reconfiguring setups swiftly, boosting overall efficiency. Raytone’s approach emphasizes such modularity, providing reliable options that evolve with technological trends.

Sustainable Innovations in Brick Making Equipment

Sustainability drives many updates in brick production tech, focusing on reducing environmental footprints without sacrificing output. These changes help meet regulations and appeal to eco-aware clients in construction. Raytone Machinery commits to cost-effective, green solutions in our range of brick machines, supporting reliable performance for global applications.

Energy-Efficient Power Systems

Hybrid power setups now combine electricity with solar panels, slashing reliance on fossil fuels in brick manufacturing. These systems store excess energy for peak times, ensuring uninterrupted operation. Professional analysis shows they lower operational costs by up to 30 percent in sunny regions. Clay processing benefits from efficient motors that minimize heat loss during mixing and pressing. Integration of regenerative braking in conveyors recaptures energy, enhancing overall sustainability. Brick strength remains uncompromised, as precise controls maintain optimal conditions. Adoption grows in areas with variable power grids, providing stability and reducing emissions.

Waste Reduction and Material Recycling Features

Machines incorporate recyclers that repurpose excess clay and water from production cycles, cutting raw material needs. Filters capture fine particles for reuse, preventing landfill waste. Detailed engineering includes closed-loop systems where slurry gets cleaned and reinjected into mixers. This approach boosts efficiency by conserving resources, vital for large-scale operations. Brick quality improves with consistent recycled mixes, yielding durable products for building. Sensors detect impurities, ensuring purity in every batch. Global manufacturers appreciate how these features align with circular economy principles, fostering long-term viability.

Eco-Friendly Clay Sourcing and Processing

Innovations enable processing of alternative clays, like those mixed with industrial byproducts, reducing mining impacts. Clay brick making machines adjust automatically to varying clay compositions, maintaining output quality. In professional contexts, this supports sustainable sourcing from certified suppliers. Enhanced extrusion tech minimizes water use through efficient hydration controls. Bricks emerge with lower carbon footprints, appealing to green building certifications. Raytone’s equipment handles these processes reliably, offering versatility for diverse clay types worldwide.

Smart Technologies Enhancing Brick Machine Operations

Smart tech brings intelligence to brick making, using data and connectivity to optimize every step. This evolution makes machines more intuitive and responsive, benefiting users in construction machinery. Raytone Machinery incorporates these elements into our high-quality brick solutions, ensuring performance and value for customers.

AI and Machine Learning Applications

AI algorithms predict maintenance needs by analyzing vibration patterns, preventing breakdowns before they occur. Machine learning refines recipes based on past runs, improving clay mix efficiency over time. Professionals rely on these for consistent brick density and strength. Systems learn from environmental data, adjusting for humidity to avoid defects. Integration with production lines enables real-time tweaks, enhancing throughput. Brick aesthetics benefit from AI-optimized coloring and texturing. Operators gain insights via dashboards, simplifying complex decisions.

IoT Connectivity for Remote Monitoring

Internet of Things devices link clay brick making machines to cloud platforms, allowing remote oversight of operations. Sensors track parameters like temperature and speed, sending alerts for anomalies. Detailed logs help in troubleshooting, reducing on-site visits. In global setups, this connectivity supports multi-site management from one hub. Brick quality control tightens with instant data sharing among teams. Energy usage gets optimized through connected analytics, cutting waste. Raytone’s models feature secure IoT interfaces, ensuring data protection and reliable performance.

Data Analytics for Performance Optimization

Analytics tools process production data to identify bottlenecks, suggesting improvements like speed adjustments. Patterns in output reveal ways to enhance brick durability and reduce rejects. Professional users leverage this for strategic planning, forecasting demand accurately. Integration with supply chains streamlines material orders based on usage trends. Machines evolve through firmware updates driven by analytics, staying current. Overall efficiency rises, leading to cost savings and better resource allocation in brick manufacturing.

Conclusion

Innovations in clay brick making machine technology emphasize automation, sustainability, and smart features, driving efficiency and eco-friendliness. These advancements help businesses produce high-quality bricks with less waste and energy. By embracing them, manufacturers can stay competitive in construction markets. Raytone Machinery leads with reliable, versatile solutions that incorporate these trends. Explore how they fit your needs to future-proof your operations.

Contact Us

Ready to upgrade your brick production? Raytone Machinery provides high-quality, cost-effective brick machines designed for performance, reliability, and versatility in construction and home building. Contact us at hazel@raytonechina.com for expert guidance and product details.

References

- “Brick: A World History” by James W. P. Campbell and Will Pryce, published by Thames & Hudson, 2003.

- “Sustainable Ceramics” by Robert Harrison, published by Bloomsbury Visual Arts, 2013.

- “The Chemistry of Clay-Organic Reactions” by Benny K. G. Theng, published by CRC Press, 2014.

- “Advances in Brick and Block” edited by John Morton, published by Butterworth-Heinemann, 1999.

- “Ceramic Processing and Sintering” by Mohamed N. Rahaman, published by CRC Press, 2003.

- “Industrial Ceramics” by F. Singer and S. S. Singer, published by Springer, 1963.