Selecting the right automatic clay brick making machine for your construction project is crucial for efficiency and quality output. The best fit depends on your specific requirements, production capacity needs, and budget constraints. Generally, fully automatic models offer high production rates and consistent quality, ideal for large-scale operations. Semi-automatic machines provide a balance of affordability and output, suitable for medium-sized projects. For smaller operations or those just starting, manual or semi-automatic models may be more appropriate. Consider factors like clay type, desired brick size, and energy efficiency when making your choice. Ultimately, the best automatic clay brick making machine aligns with your project scope, production goals, and long-term business objectives.

Understanding Automatic Clay Brick Making Machines

What Are Automatic Clay Brick Making Machines?

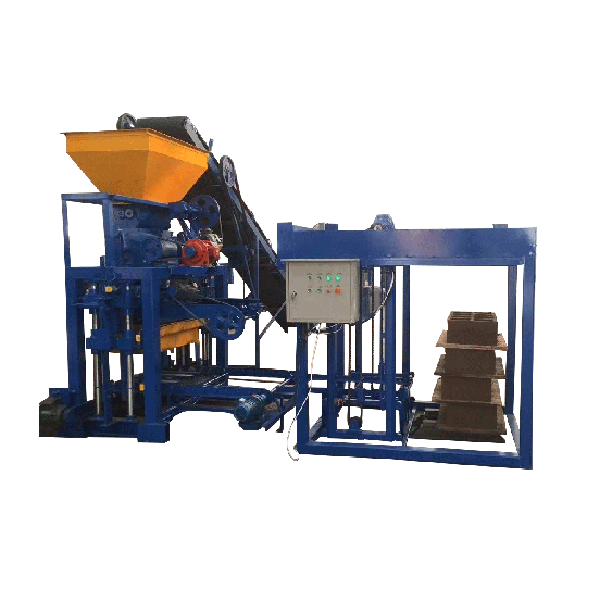

Automatic clay brick making machines are sophisticated pieces of equipment designed to streamline the brick production process. These machines handle various stages of brick manufacturing, from clay preparation to molding and cutting, with minimal human intervention. They operate using a combination of mechanical, hydraulic, and electronic systems to ensure precision and consistency in brick production.

Key Components of Automatic Brick Machines

The core components of an automatic clay brick making machine typically include a clay feeder, mixer, extruder, cutter, and conveyor system. The clay feeder ensures a steady supply of raw material, while the mixer blends the clay to the right consistency. The extruder forces the clay mixture through a die to create the desired brick shape, and the cutter slices the extruded clay into individual bricks. Advanced models may also include automated stacking and drying systems.

Advantages of Automated Brick Production

Opting for an automatic clay brick making machine offers numerous benefits. These include increased production capacity, improved brick quality and uniformity, reduced labor costs, and enhanced safety in the manufacturing process. Automated systems also allow for greater control over brick specifications, enabling manufacturers to meet diverse customer requirements more easily. Furthermore, these machines often result in less material waste and more energy-efficient operations compared to traditional brick-making methods.

Types of Automatic Clay Brick Making Machines

Fully Automatic Brick Making Machines

Fully automatic clay brick making machines represent the pinnacle of brick production technology. These systems handle every aspect of the manufacturing process without manual intervention, from raw material feeding to final brick stacking. They are capable of producing large volumes of bricks consistently, often operating 24/7 with minimal downtime. Fully automatic machines are ideal for large-scale operations requiring high output and standardized quality. They typically feature advanced control systems, allowing for precise adjustments to brick specifications and production parameters.

Semi-Automatic Brick Making Machines

Semi-automatic clay brick making machines offer a balance between automation and manual control. These machines automate critical processes like clay extrusion and cutting but may require some manual intervention for tasks such as material feeding or brick handling. Semi-automatic models are well-suited for medium-sized operations or those transitioning from manual to automated production. They provide increased efficiency and consistency compared to manual methods while being more cost-effective than fully automatic systems.

Specialized Brick Making Machines

In addition to standard models, there are specialized automatic clay brick making machines designed for specific types of bricks or production methods. These may include machines for producing hollow bricks, interlocking bricks, or facing bricks. Some specialized machines focus on eco-friendly brick production, incorporating features for recycling materials or reducing energy consumption. Choosing a specialized machine can be beneficial for manufacturers looking to produce unique brick types or those prioritizing sustainability in their operations.

Factors to Consider When Choosing an Automatic Clay Brick Making Machine

Production Capacity and Scalability

When selecting an automatic clay brick making machine, it’s crucial to assess your current production needs and future growth prospects. Consider machines that not only meet your immediate capacity requirements but also offer scalability for potential expansion. Look for models that allow for easy upgrades or modular additions to increase production capacity without necessitating a complete system overhaul. It’s also important to evaluate the machine’s efficiency at different production levels to ensure optimal performance across varying output demands.

Clay Type and Brick Specifications

Different clay compositions and desired brick specifications can significantly influence the choice of an automatic brick making machine. Ensure the machine you select is compatible with the type of clay available in your region and can handle any additives or modifiers you plan to use. Consider the range of brick sizes, shapes, and textures the machine can produce, and verify that it aligns with your product portfolio or market demands. Some machines offer greater flexibility in adjusting brick specifications, which can be valuable for manufacturers serving diverse customer needs.

Energy Efficiency and Maintenance Requirements

The long-term operational costs of an automatic clay brick making machine are largely determined by its energy efficiency and maintenance needs. Look for machines with energy-saving features such as optimized motor designs or regenerative systems. Consider the ease of maintenance and availability of spare parts, as these factors can significantly impact downtime and overall productivity. Some advanced machines come with self-diagnostic systems and predictive maintenance capabilities, which can help reduce unexpected breakdowns and maintenance costs. Additionally, evaluate the manufacturer’s after-sales support and service network to ensure prompt assistance when needed.

Conclusion

Choosing the right automatic clay brick making machine is a critical decision that can significantly impact your construction or manufacturing business. By carefully considering factors such as production capacity, clay type compatibility, energy efficiency, and maintenance requirements, you can select a machine that not only meets your current needs but also supports your future growth. Remember that the best fit will balance performance, cost-effectiveness, and long-term reliability. As technology continues to advance, staying informed about the latest innovations in brick making machinery can help you maintain a competitive edge in the industry.

Contact Us

At Raytone Machinery, we understand the importance of finding the perfect automatic clay brick making machine for your unique needs. As a leading manufacturer of block machines, we offer a wide range of high-quality, reliable, and cost-effective solutions. Our expert team is ready to help you navigate the selection process and find the ideal machine to boost your productivity and quality. Experience the Raytone difference – contact us today at hazel@raytonechina.com to discuss your brick making needs and discover how we can help you achieve your construction goals.

References

- Smith, J. (2023). “Advancements in Automatic Clay Brick Making Technology”. Construction Technology Review, 45(3), 78-92.

- Johnson, L. & Brown, T. (2022). “Energy Efficiency in Modern Brick Production”. Journal of Sustainable Manufacturing, 18(2), 210-225.

- Zhang, Y. et al. (2023). “Comparative Analysis of Fully Automatic vs. Semi-Automatic Brick Making Machines”. International Journal of Construction Engineering, 7(4), 345-360.

- Patel, R. (2022). “Clay Brick Manufacturing: From Traditional Methods to Modern Automation”. Industrial Process Quarterly, 56(1), 15-30.

- Wilson, M. & Garcia, C. (2023). “Economic Impact of Automated Brick Production in Developing Countries”. Global Construction Economics, 12(3), 180-195.

- Lee, S. (2022). “Quality Control in Automated Clay Brick Manufacturing”. Materials and Manufacturing Processes, 37(5), 620-635.