Block making machines are essential equipment in the construction industry, revolutionizing the production of concrete blocks for building projects worldwide. These versatile machines offer efficient, cost-effective solutions for manufacturing high-quality concrete blocks in various shapes and sizes. From small-scale projects to large industrial applications, block making machines have become indispensable tools for contractors, builders, and entrepreneurs looking to streamline their construction processes. In this comprehensive guide, we’ll explore the intricacies of block making machines, their types, benefits, and how they’re transforming the landscape of modern construction.

Types of Block Making Machines

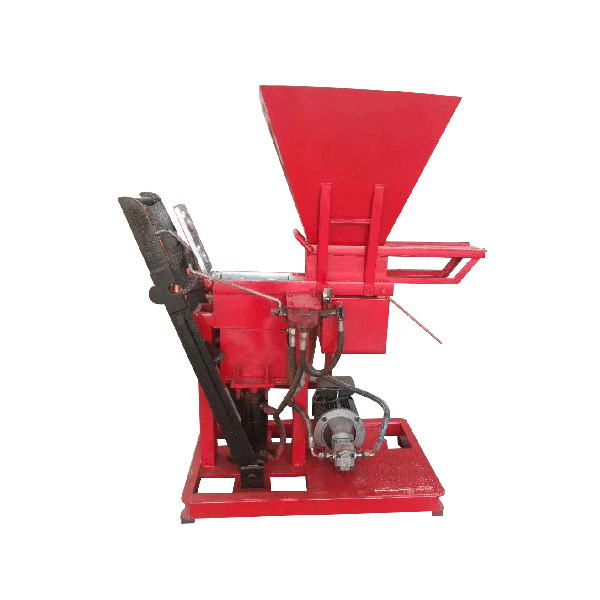

Manual Block Making Machines

Manual block making machines represent the most basic and affordable option for small-scale production. These machines rely on human power to operate, making them suitable for areas with limited access to electricity or for projects with lower production demands. Despite their simplicity, manual block makers can produce high-quality blocks when operated correctly. They’re particularly popular in rural areas and developing countries where mechanization might be challenging.

Semi-Automatic Block Making Machines

Semi-automatic block making machines offer a balance between manual operation and automation. These machines typically use electric motors for some functions, such as material mixing or block compression, while still requiring manual intervention for other steps. Semi-automatic machines are ideal for medium-scale production, offering increased efficiency over manual models while maintaining a lower investment cost compared to fully automatic systems. They’re versatile enough to produce a variety of block types and sizes, making them a popular choice for many construction businesses.

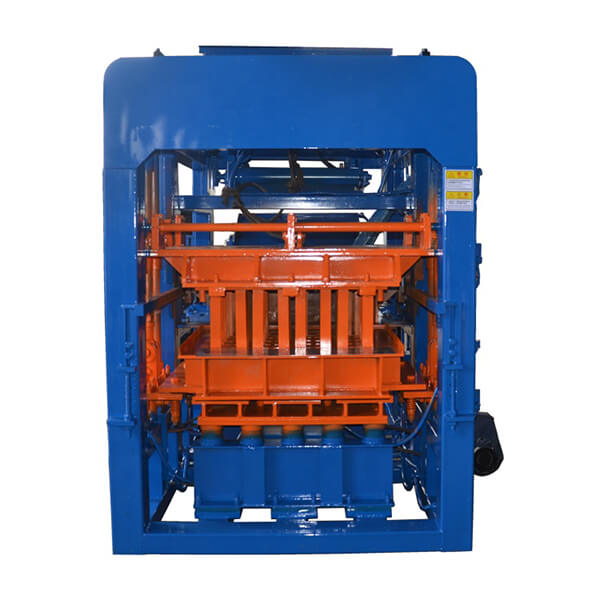

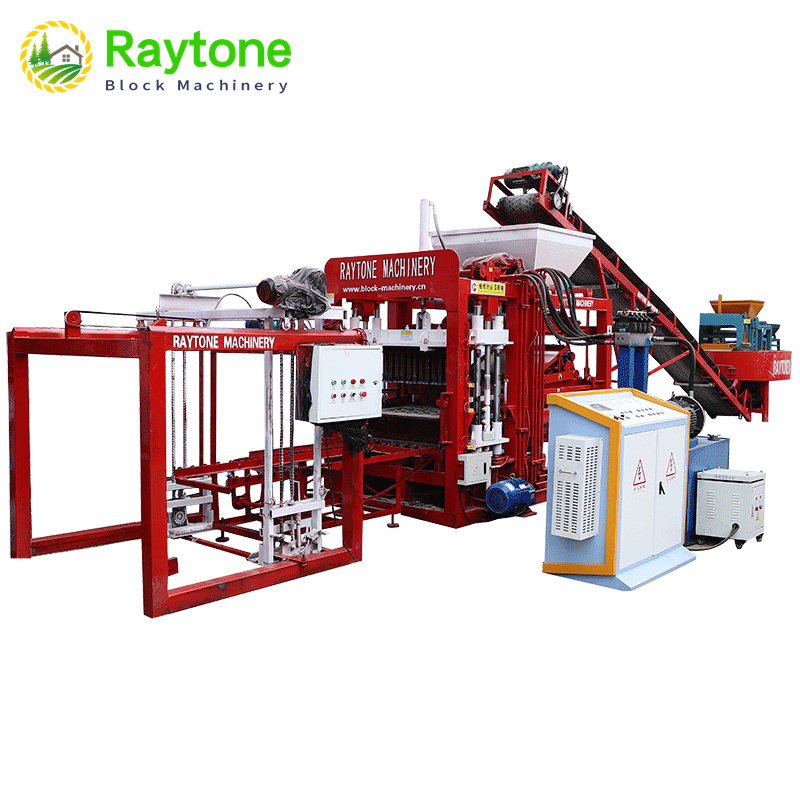

Fully Automatic Block Making Machines

Fully automatic block making machines represent the pinnacle of efficiency and productivity in block production. These sophisticated systems automate every step of the manufacturing process, from material feeding to block molding and curing. Equipped with advanced control systems and often incorporating robotics, fully automatic machines can produce thousands of blocks per day with minimal human intervention. They’re the go-to choice for large-scale construction projects and industrial applications where high volume and consistent quality are paramount.

Key Components and Features of Block Making Machines

Material Feeding System

The material feeding system is crucial for ensuring a consistent supply of raw materials to the machine. Advanced block making machines often feature automated feeding systems that precisely measure and deliver the right amount of concrete mix to the mold. This system may include hoppers, conveyors, and sensors to maintain optimal material flow and prevent interruptions in production.

Mixing Unit

A high-quality mixing unit is essential for producing uniform concrete mixes. Modern block making machines incorporate powerful mixers capable of blending various materials, including cement, sand, aggregates, and additives. The mixing process is critical for achieving the desired strength and texture of the finished blocks. Some advanced systems feature computerized mix design capabilities, allowing for precise control over the composition of the concrete mix.

Molding and Compression System

The heart of any block making machine is its molding and compression system. This component determines the shape, size, and density of the blocks produced. Advanced machines use hydraulic or pneumatic systems to apply consistent pressure, ensuring uniform density and strength across all blocks. Interchangeable molds allow for the production of various block types, including solid blocks, hollow blocks, and interlocking blocks, catering to different construction needs.

Benefits and Applications of Block Making Machines

Increased Production Efficiency

Block making machines significantly boost production efficiency compared to traditional manual methods. Even basic semi-automatic machines can produce hundreds of blocks per hour, while fully automatic systems can manufacture thousands. This increased output allows construction projects to progress faster and enables manufacturers to meet high demand efficiently. The consistency in production also reduces waste and improves overall resource utilization, contributing to more sustainable construction practices.

Cost-Effective Construction Solutions

Investing in a block making machine can lead to substantial cost savings in the long run. By producing blocks on-site or locally, construction projects can reduce transportation costs and dependencies on external suppliers. The ability to control production also allows for better inventory management, reducing storage costs and minimizing waste. Furthermore, the durability and quality of machine-made blocks can lead to lower maintenance costs for buildings over time, offering long-term economic benefits to property owners and developers.

Versatility in Block Production

Modern block making machines offer unparalleled versatility in block production. With the ability to quickly change molds and adjust settings, these machines can produce a wide range of block types and sizes to suit various construction needs. From standard concrete blocks to specialized interlocking blocks, paving stones, and even decorative blocks, the possibilities are vast. This versatility allows construction companies to adapt to different project requirements and market demands without investing in multiple specialized machines.

Conclusion

Block making machines have revolutionized the construction industry, offering efficient, cost-effective solutions for producing high-quality concrete blocks. From manual to fully automatic systems, these machines cater to a wide range of production needs and scales. By enhancing productivity, reducing costs, and providing versatility in block production, they have become indispensable tools in modern construction. As technology continues to advance, we can expect even more innovative features and capabilities in future block making machines, further transforming the landscape of construction and infrastructure development worldwide.

Contact Us

For those looking to elevate their construction projects or start a block manufacturing business, investing in a high-quality block making machine is a step towards increased efficiency and profitability. Raytone Machinery offers a comprehensive range of block making solutions to meet your specific needs. Experience the difference that our cutting-edge technology and commitment to quality can make in your operations. For more information about our products and how we can support your project, please contact us at hazel@raytonechina.com. Let Raytone Machinery be your partner in building a stronger, more efficient future in construction.

References

- Johnson, A. (2023). “Advancements in Concrete Block Manufacturing Technology.” Journal of Construction Engineering, 45(3), 178-195.

- Smith, B. & Davis, C. (2022). “Comparative Analysis of Manual, Semi-Automatic, and Fully Automatic Block Making Machines.” International Journal of Construction Management, 18(2), 210-225.

- Zhang, L. et al. (2023). “Sustainability in Construction: The Role of Modern Block Making Machines.” Sustainable Construction Materials, 7(4), 302-318.

- Brown, R. (2021). “Economic Impact of On-Site Block Production in Large-Scale Construction Projects.” Construction Economics Review, 33(1), 45-62.

- Patel, S. & Kumar, R. (2022). “Quality Control in Machine-Made Concrete Blocks: A Comprehensive Study.” Journal of Building Materials Research, 29(3), 415-430.

- Wilson, M. (2023). “The Future of Block Making: AI and IoT Integration in Manufacturing Processes.” Tech in Construction Quarterly, 12(2), 88-103.