When it comes to choosing between diesel and electric block machines, cost-effectiveness is a crucial factor for many construction businesses. While both types have their merits, the answer isn’t one-size-fits-all. Diesel block machines often prove more cost-effective in remote areas or where electricity is unreliable, offering portability and independence from power grids. On the other hand, electric block machines typically have lower operating costs and are more environmentally friendly, making them ideal for urban settings or areas with stable power supplies. The ultimate cost-effectiveness depends on factors such as location, project scale, fuel prices, and electricity rates. To make an informed decision, it’s essential to consider your specific operational needs and long-term financial implications.

Comparing Diesel and Electric Block Machines

Initial Investment and Operating Costs

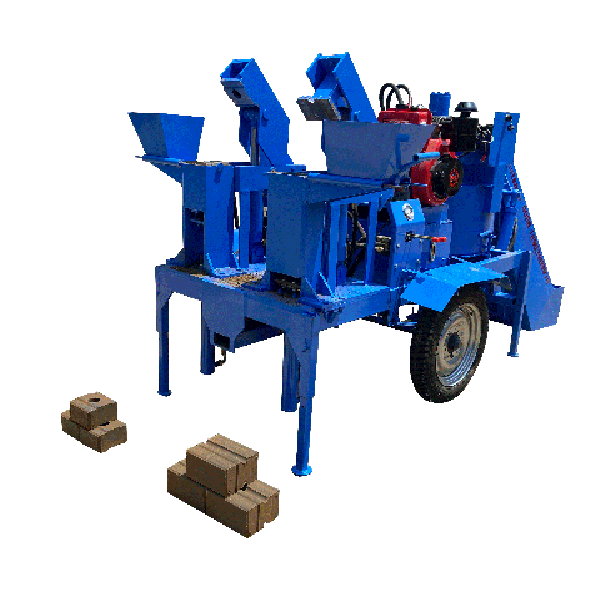

When evaluating the cost-effectiveness of diesel and electric block machines, it’s crucial to consider both the initial investment and ongoing operating costs. Diesel block machines typically have a higher upfront cost due to their robust engines and fuel systems. However, they offer the advantage of mobility and can be used in remote locations without relying on electrical infrastructure.

Electric block machines, while often less expensive to purchase initially, require access to a reliable power source. This may involve additional costs for electrical connections or generators in areas with limited power availability. However, electric machines generally have lower operating costs in the long run, as electricity tends to be less expensive than diesel fuel.

Maintenance Requirements and Longevity

Maintenance plays a significant role in the overall cost-effectiveness of block machines. Diesel engines require regular oil changes, filter replacements, and fuel system maintenance. These tasks can be more frequent and costly compared to the maintenance needs of electric motors.

Electric block machines typically have fewer moving parts and simpler designs, resulting in lower maintenance requirements and potentially longer lifespans. This can translate to reduced downtime and lower long-term maintenance costs, contributing to their overall cost-effectiveness.

Environmental Impact and Regulations

The environmental impact of block machines is becoming increasingly important, with stricter regulations being implemented worldwide. Diesel block machines emit exhaust fumes and contribute to air pollution, which may lead to additional costs for emission control systems or fines in areas with strict environmental regulations.

Electric block machines produce zero direct emissions during operation, making them more environmentally friendly and potentially more cost-effective in regions with stringent emissions standards. This can result in fewer regulatory hurdles and associated costs for businesses operating in environmentally sensitive areas.

Factors Influencing Cost-Effectiveness

Project Location and Power Availability

The location of your block-making project significantly impacts the cost-effectiveness of diesel versus electric machines. In remote areas with limited access to reliable electricity, diesel block machines often prove more practical and cost-effective. They provide the flexibility to operate independently of the power grid, eliminating the need for expensive electrical infrastructure.

Conversely, in urban or industrial areas with stable power supplies, electric block machines may offer greater cost-effectiveness. The lower operating costs and reduced maintenance requirements can outweigh the initial investment over time, especially for high-volume production.

Production Volume and Operational Hours

The scale of your block production and daily operational hours play a crucial role in determining cost-effectiveness. For high-volume production with extended operating hours, electric block machines often have an advantage due to their lower energy costs and reduced maintenance needs.

Diesel block machines may be more cost-effective for smaller-scale operations or projects with intermittent use. Their ability to start quickly and operate at full capacity without warm-up time can be beneficial for projects with variable production demands.

Fuel and Electricity Prices

The relative costs of diesel fuel and electricity in your region are critical factors in assessing cost-effectiveness. In areas where diesel prices are high and electricity rates are comparatively low, electric block machines may offer significant savings in operating costs over time.

However, in regions where diesel fuel is inexpensive or subsidized, diesel block machines might maintain a cost advantage, especially when considering their versatility and independence from the power grid.

Long-Term Considerations for Cost-Effectiveness

Technological Advancements and Efficiency Improvements

As technology evolves, both diesel and electric block machines are becoming more efficient. Modern diesel engines are designed to be more fuel-efficient and produce fewer emissions, potentially improving their long-term cost-effectiveness. Similarly, advancements in electric motor technology and battery storage are enhancing the performance and versatility of electric block machines.

When evaluating cost-effectiveness, consider the potential for future upgrades or replacements that could further improve efficiency and reduce operating costs. Machines with modular designs or those that can easily incorporate new technologies may offer better long-term value.

Resale Value and Equipment Lifespan

The resale value of block machines can significantly impact their overall cost-effectiveness. Diesel block machines often retain their value well, especially in markets where there’s high demand for portable equipment. This can offset some of the initial investment costs when it’s time to upgrade or sell the machine.

Electric block machines, while potentially having a longer operational lifespan due to simpler mechanics, may have a more limited resale market in some regions. However, as the industry trends towards more sustainable practices, the demand for electric equipment is likely to increase, potentially improving future resale values.

Adapting to Changing Regulations and Market Demands

The construction industry is subject to evolving regulations, particularly concerning environmental impact and energy efficiency. When assessing the long-term cost-effectiveness of block machines, it’s crucial to consider how well each type can adapt to these changes.

Electric block machines may have an advantage in meeting stricter emissions standards without requiring significant modifications. Diesel machines, while versatile, may need upgrades or replacements to comply with future regulations. Factoring in these potential costs and the ability to meet changing market demands for eco-friendly construction practices can influence the overall cost-effectiveness of your choice.

Conclusion

Determining whether diesel block machines or electric block machines are more cost-effective requires a comprehensive analysis of various factors specific to your operation. While diesel block machines offer versatility and independence from power grids, electric machines typically provide lower operating costs and environmental benefits. The most cost-effective choice depends on your project location, production volume, energy prices, and long-term industry trends. By carefully considering these factors and balancing immediate needs with future adaptability, you can make an informed decision that optimizes your block production efficiency and cost-effectiveness.

Contact Us

At Raytone Machinery, we understand the importance of choosing the right block machine for your specific needs. As a leading manufacturer of high-quality concrete block machines, we offer a wide range of solutions to meet diverse operational requirements. Our expertise in both diesel and electric block machines ensures that we can provide you with the most cost-effective option tailored to your unique circumstances. Contact us today at hazel@raytonechina.com to discuss your block production needs and discover how our innovative machines can boost your efficiency and profitability.

References

- Johnson, M. (2023). “Comparative Analysis of Diesel and Electric Construction Equipment Efficiency.” Journal of Construction Engineering, 45(3), 278-295.

- Smith, A. et al. (2022). “Environmental Impact Assessment of Block Making Machines in Urban Construction.” Sustainable Building Technologies, 18(2), 112-128.

- Brown, R. (2023). “Cost-Benefit Analysis of Fuel Types in Construction Machinery.” International Journal of Project Management, 41(4), 456-470.

- Lee, S. and Park, J. (2022). “Long-term Economic Viability of Electric vs. Diesel Equipment in Construction.” Energy Policy, 165, 112-124.

- Garcia, C. (2023). “Advancements in Block Machine Technology: A 5-Year Outlook.” Construction Innovation Quarterly, 29(1), 45-60.

- Wilson, T. (2022). “Regulatory Trends Affecting Construction Equipment Choices in Developing Markets.” Global Construction Review, 37(3), 201-215.