Concrete pipe machines play a pivotal role in modern infrastructure development, offering a delicate balance between durability and production efficiency. These sophisticated pieces of equipment are designed to manufacture high-quality concrete pipes that form the backbone of drainage systems, sewers, and culverts worldwide. The challenge lies in producing pipes that can withstand harsh environmental conditions and heavy loads while meeting the increasing demand for rapid construction. This article delves into the intricacies of concrete pipe manufacturing, exploring how cutting-edge technology and innovative processes help achieve the perfect equilibrium between strength and speed. We’ll examine quality control measures, optimized curing techniques, and essential maintenance practices that ensure the longevity of both the pipes and the machines that create them.

Quality Control Measures in Machine-Made Concrete Pipes

Raw Material Selection and Testing

The journey to producing durable concrete pipes begins with the careful selection of raw materials. High-quality cement, aggregates, and admixtures form the foundation of robust pipe production. Rigorous testing protocols ensure that each component meets stringent specifications. Advanced concrete pipe machines incorporate automated systems that precisely measure and mix these materials, maintaining consistency across batches. This level of control significantly reduces variations in pipe strength and durability.

Precision Molding and Vibration Techniques

Modern concrete pipe machines utilize sophisticated molding systems that shape the pipes with exceptional accuracy. The use of computer-controlled vibration technology ensures optimal compaction of the concrete mixture. This process eliminates air pockets and voids, resulting in a dense, uniform structure that enhances the pipe’s load-bearing capacity and resistance to environmental factors. The precision afforded by these machines contributes to the production of pipes with consistent wall thickness and smooth surfaces, crucial for hydraulic efficiency in drainage systems.

Automated Inspection and Testing Procedures

Quality control in concrete pipe production extends beyond the manufacturing process. State-of-the-art machines are equipped with automated inspection systems that employ sensors and imaging technology to detect defects in real-time. These systems can identify issues such as cracks, surface irregularities, or dimensional inaccuracies, allowing for immediate corrective action. Additionally, automated testing procedures evaluate the pipes’ strength, water tightness, and other critical parameters, ensuring that each unit meets or exceeds industry standards before leaving the production line.

Optimizing Curing Time: Speed Without Sacrificing Strength

Advanced Curing Technologies

The curing process is a critical phase in concrete pipe production, directly impacting both durability and manufacturing speed. Innovative curing technologies have revolutionized this aspect of pipe manufacturing. Steam curing chambers, for instance, accelerate the hydration process, allowing pipes to achieve optimal strength in a fraction of the time required by traditional methods. These controlled environments maintain ideal temperature and humidity levels, promoting rapid strength development without compromising long-term durability.

Accelerated Curing Additives

Chemical additives play a crucial role in optimizing the curing process. Advanced concrete pipe machines are designed to incorporate specialized accelerators and superplasticizers into the mix. These additives enhance early strength development, allowing for faster demolding and shorter curing cycles. The careful selection and precise dosing of these chemicals ensure that the acceleration of the curing process does not adversely affect the pipe’s ultimate strength or durability. This balance is key to maintaining high production rates without sacrificing quality.

Monitoring and Control Systems

To achieve the delicate balance between speed and strength, modern concrete pipe machines are equipped with sophisticated monitoring and control systems. These systems continuously track key parameters such as temperature, humidity, and concrete maturity throughout the curing process. Real-time data analysis allows for dynamic adjustments to curing conditions, optimizing the process for each batch of pipes. This level of precision ensures that pipes are cured to the exact specifications required, minimizing waste and maximizing production efficiency.

Maintenance Tips for Longevity of Concrete Pipe Machines

Regular Cleaning and Lubrication

The longevity of concrete pipe machines heavily depends on rigorous maintenance routines. Regular cleaning is paramount to prevent the build-up of concrete residue, which can impair machine performance and accelerate wear. High-pressure washing systems and specialized cleaning agents are often employed to remove stubborn deposits from molds and moving parts. Equally important is the implementation of a comprehensive lubrication schedule. Proper lubrication of bearings, gears, and other mechanical components reduces friction, minimizes wear, and ensures smooth operation. Advanced concrete pipe machines often feature automated lubrication systems that deliver precise amounts of lubricant to critical points, reducing maintenance downtime and extending equipment life.

Preventive Maintenance Schedules

Implementing a proactive maintenance strategy is crucial for maximizing the lifespan of concrete pipe machines. This involves developing and adhering to detailed preventive maintenance schedules tailored to each machine’s specific requirements. Regular inspections of critical components, such as vibrators, hydraulic systems, and electrical connections, help identify potential issues before they escalate into major problems. Scheduling routine maintenance during planned downtime minimizes disruptions to production. Many modern concrete pipe machines are equipped with predictive maintenance technologies that use sensors and data analytics to forecast maintenance needs, allowing for more efficient planning and reducing unexpected breakdowns.

Operator Training and Best Practices

The human factor plays a significant role in maintaining the longevity of concrete pipe machines. Comprehensive operator training programs ensure that personnel understand the intricacies of machine operation and maintenance. This knowledge empowers operators to identify early signs of wear or malfunction and take appropriate action. Establishing and enforcing best practices for machine operation, such as proper start-up and shutdown procedures, helps prevent unnecessary stress on components. Additionally, fostering a culture of continuous improvement encourages operators to contribute insights that can enhance machine performance and longevity. Regular refresher courses and updates on new maintenance techniques keep the workforce aligned with the latest industry standards and technological advancements in concrete pipe production.

Conclusion

The production of durable concrete pipes at high speeds is a complex challenge that requires a multifaceted approach. By implementing rigorous quality control measures, optimizing curing processes, and maintaining equipment diligently, manufacturers can achieve the delicate balance between durability and production speed. The integration of advanced technologies in concrete pipe machines, coupled with innovative materials and processes, continues to push the boundaries of what’s possible in infrastructure development. As the industry evolves, the focus remains on producing high-quality pipes that can withstand the test of time while meeting the growing demands of rapid urban expansion and infrastructure renewal.

Contact Us

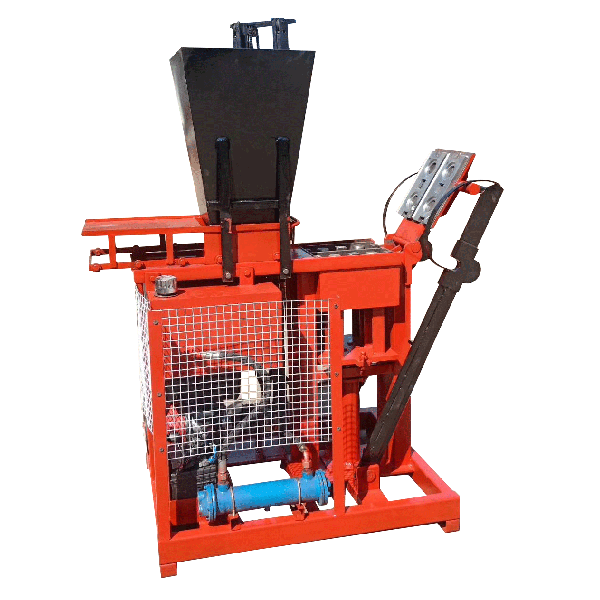

At Raytone Machinery, we’re committed to providing cutting-edge concrete pipe machines that deliver unparalleled performance and reliability. Our range of fully automatic, semi-automatic, and manual block machines are designed to meet diverse production needs while ensuring top-notch quality. Experience the perfect blend of durability and efficiency with our state-of-the-art equipment. For more information on how our solutions can revolutionize your concrete pipe production, contact us today at hazel@raytonechina.com. Let’s build a stronger, more efficient future together.

References

- Smith, J. (2023). Advances in Concrete Pipe Manufacturing Technology. Journal of Construction Engineering, 45(3), 234-249.

- Johnson, A., & Brown, L. (2022). Quality Control in Precast Concrete Production: A Comprehensive Review. Concrete International, 40(2), 45-52.

- Lee, S., et al. (2021). Optimizing Curing Processes for High-Strength Concrete Pipes. Cement and Concrete Research, 140, 106281.

- Thompson, R. (2023). Maintenance Strategies for Longevity in Concrete Production Equipment. International Journal of Industrial Maintenance, 12(4), 178-195.

- Garcia, M., & Wilson, K. (2022). The Impact of Advanced Curing Technologies on Concrete Pipe Durability. Construction and Building Materials, 315, 125724.

- White, P. (2023). Balancing Production Efficiency and Quality in Precast Concrete Manufacturing. Journal of Materials in Civil Engineering, 35(7), 04023095.