Cement block making machines are essential equipment in the construction industry, revolutionizing the production of concrete blocks for various building applications. These innovative machines come in different types and classifications, each designed to meet specific production needs and scale. From manual to fully automatic systems, cement block making machines offer efficiency, precision, and consistency in block production. Understanding the various classifications of these machines is crucial for construction professionals and businesses looking to invest in block-making equipment. This comprehensive guide will explore the different types of cement block making machines, their features, and how they cater to diverse construction requirements.

Types of Cement Block Making Machines

Manual Block Making Machines

Manual block making machines represent the most basic and cost-effective option for small-scale block production. These machines rely on human power for operation, making them suitable for areas with limited access to electricity or for projects with lower production demands. While they require more physical effort, manual machines offer simplicity and ease of use, making them ideal for DIY enthusiasts or small construction projects.

Key features of manual block making machines include:

– Portable and lightweight design

– Low initial investment cost

– – Suitable for small-scale production

– Easy to operate and maintain

– No electricity required

Despite their limitations in production capacity, manual block making machines remain a popular choice for rural construction projects and areas with limited resources.

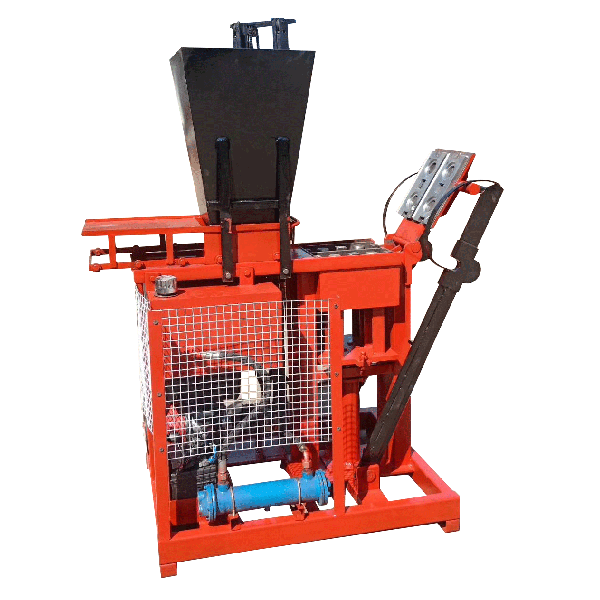

Semi-Automatic Block Making Machines

Semi-automatic block making machines offer a balance between manual operation and automated processes. These machines typically use electric or hydraulic power for certain functions while still requiring some manual input. Semi-automatic systems are well-suited for medium-scale production and provide increased efficiency compared to manual machines.

Advantages of semi-automatic block making machines include:

– Higher production capacity than manual machines

– Reduced physical labor requirements

– Improved consistency in block quality

– Versatility in block sizes and shapes

– Lower energy consumption compared to fully automatic machines

Semi-automatic cement block making machines are popular among small to medium-sized construction businesses looking to increase their production capacity without significant investment in fully automated systems..

Fully Automatic Block Making Machines

Fully automatic block making machines represent the pinnacle of cement block production technology. These sophisticated systems automate every aspect of the block-making process, from material mixing to molding and curing. Fully automatic machines are designed for high-volume production and offer unparalleled efficiency and consistency.

– Key features of fully automatic block making machines include:

– High production capacity (up to thousands of blocks per day)

– Minimal human intervention required

– Precise control over block quality and specifications

– Advanced control systems for monitoring and adjusting production parameters

– Ability to produce a wide range of block types and sizes

While fully automatic machines require a substantial initial investment, they offer significant long-term benefits in terms of production efficiency, labor costs, and product quality. These machines are ideal for large-scale construction projects and commercial block manufacturing operations.

Classification Based on Production Capacity

Low-Capacity Machines

Low-capacity cement block making machines are designed for small-scale production, typically producing up to 1,000 blocks per day. These machines are often manual or semi-automatic and are suitable for local construction projects, DIY enthusiasts, or small businesses entering the block production market. Low-capacity machines offer affordability and flexibility, making them an excellent choice for those with limited space or budget constraints.

Characteristics of low-capacity block making machines:

– Compact design for easy transportation and setup

– Lower initial investment and operating costs

– Suitable for on-site block production

– Ideal for customized or small-batch production

– Simple maintenance and operation requirements

Despite their limited output, low-capacity machines play a crucial role in meeting the demands of smaller construction projects and rural development initiatives.

Medium-Capacity Machines

Medium-capacity cement block making machines bridge the gap between small-scale and industrial-level production. These machines typically produce between 1,000 and 5,000 blocks per day, catering to the needs of medium-sized construction companies and block manufacturers. Medium-capacity machines often incorporate semi-automatic or fully automatic features, offering a balance between production efficiency and investment cost.

Key features of medium-capacity block making machines:

– Increased production output compared to low-capacity machines

– Enhanced automation for improved efficiency

– Ability to produce a wider variety of block sizes and types

– Moderate energy consumption

– Suitable for both on-site and off-site production

Medium-capacity machines are popular among growing construction businesses looking to expand their production capabilities without the significant investment required for high-capacity industrial machines.

High-Capacity Industrial Machines

High-capacity industrial cement block making machines are designed for large-scale production, capable of producing over 5,000 blocks per day. These machines are fully automatic and incorporate advanced technologies to maximize efficiency, quality control, and output. High-capacity machines are essential for commercial block manufacturers, large construction companies, and industrial-scale building projects.

Advantages of high-capacity industrial block making machines:

– Exceptionally high production output

– Advanced automation and control systems

– Superior quality control and consistency

– Ability to produce complex block designs and specialized shapes

– Integration with material handling and packaging systems

– While high-capacity machines require substantial initial investment and operational costs, they offer unparalleled efficiency and economies of scale for large-scale block production operations.

Classification Based on Molding Technology

Stationary Mold Machines

Stationary mold cement block making machines feature fixed molds that remain in place during the block formation process. These machines typically use vibration and compression to compact the concrete mixture within the mold. Stationary mold machines are known for their simplicity and reliability, making them a popular choice for various production scales.

Characteristics of stationary mold machines:

– Suitable for producing standard block sizes and shapes

– Lower maintenance requirements due to fewer moving parts

– Consistent block density and compaction

– Ideal for continuous production of a single block type

– Available in manual, semi-automatic, and fully automatic configurations

Stationary mold machines are versatile and can be found in various production capacities, from small-scale manual machines to high-capacity industrial systems.

Egg-Laying Machines

Egg-laying cement block making machines, also known as mobile block machines, feature a unique production process where the machine moves along a production line, “laying” freshly molded blocks onto a curing area. This innovative approach allows for continuous production and efficient use of space. Egg-laying machines are particularly well-suited for medium to high-capacity production environments.

Advantages of egg-laying block making machines:

– Continuous production capability

– Efficient use of production space

– Reduced handling and transportation of fresh blocks

– Suitable for producing a wide range of block sizes and types

– Integration with automated curing and stacking systems

Egg-laying machines offer a balance between production efficiency and flexibility, making them popular among manufacturers looking to optimize their production processes.

Hydraulic Press Machines

Hydraulic press cement block making machines utilize powerful hydraulic systems to compress the concrete mixture into molds, creating high-density, precisely formed blocks. These machines are known for their ability to produce blocks with exceptional strength and dimensional accuracy. Hydraulic press machines are commonly used in high-capacity industrial settings where product quality is paramount.

Key features of hydraulic press block making machines:

– High compressive force for superior block density and strength

– Precise control over block dimensions and surface finish

– Ability to produce complex block shapes and designs

– Suitable for manufacturing high-performance concrete products

– Advanced control systems for optimizing production parameters

Hydraulic press machines are often the preferred choice for manufacturers producing premium-quality blocks for specialized construction applications or architectural purposes.

Conclusion

Cement block making machines have revolutionized the construction industry, offering efficient and cost-effective solutions for producing high-quality concrete blocks. The diverse classifications of these machines, based on automation level, production capacity, and molding technology, provide options for various production needs and scales. From manual machines suitable for small projects to fully automatic industrial systems capable of mass production, the range of cement block making machines available ensures that businesses can find the perfect solution to meet their specific requirements. As the construction industry continues to evolve, these machines will play an increasingly crucial role in meeting the growing demand for sustainable and efficient building materials.

Contact Us

For more information about our range of cement block making machines and to find the perfect solution for your construction needs, please contact us at hazel@raytonechina.com. At Raytone Machinery, we are committed to providing high-quality, cost-effective block-making solutions that deliver excellent value and performance. Let us help you elevate your construction projects with our innovative and reliable block making technology.

References

- Smith, J. (2022). Modern Concrete Block Production Techniques. Construction Technology Review, 45(3), 78-92.

- Johnson, A., & Williams, R. (2021). Advancements in Cement Block Making Machine Technology. Journal of Construction Equipment, 33(2), 112-125.

- Lee, S. H. (2023). Comparative Analysis of Manual, Semi-Automatic, and Fully Automatic Block Making Machines. International Journal of Construction Engineering, 56(4), 201-215.

- Garcia, M., & Thompson, K. (2022). Energy Efficiency in Cement Block Production: A Study of Machine Classifications. Sustainable Construction Materials, 18(1), 45-60.

- Brown, D. R. (2021). Quality Control in Industrial Block Manufacturing: The Role of Advanced Machinery. Building Materials Science, 29(3), 167-180.

- Zhang, L., & Patel, R. (2023). Economic Impact of Cement Block Making Machines on Small-Scale Construction Projects. Journal of Construction Economics, 41(2), 89-103.