Selecting a high-quality small brick making machine is crucial for efficient and cost-effective brick production. To make the right choice, consider factors such as production capacity, material versatility, automation level, durability, and after-sales support. Look for machines with robust construction, precise molding systems, and user-friendly controls. Evaluate the manufacturer’s reputation, certifications, and customer reviews. Additionally, assess your specific needs, budget constraints, and long-term goals. By carefully weighing these aspects, you can invest in a small brick making machine that optimizes your production process, enhances product quality, and provides excellent return on investment for your construction or manufacturing business.

Key Factors to Consider When Selecting a Small Brick Making Machine

Production Capacity and Efficiency

When choosing a small brick making machine, production capacity is a primary consideration. Evaluate your current and projected output requirements to ensure the machine can meet your needs. Look for machines with adjustable production rates, allowing you to scale operations as demand fluctuates. Efficiency is equally important – opt for models that maximize output while minimizing energy consumption and material waste.

Modern small brick making machines often incorporate advanced hydraulic systems and optimized mold designs to enhance productivity. Some innovative features to look for include:

– Rapid mold filling and compaction mechanisms

– Quick-change mold systems for versatile production

– Automated material feeding and brick ejection processes

Remember, higher capacity doesn’t always equate to better quality. Balance production speed with precision molding to ensure consistent brick quality.

Material Versatility and Compatibility

A versatile small brick making machine should accommodate various raw materials, allowing you to produce different types of bricks. Consider machines that can work with:

– Clay

– Concrete

– Fly ash

– Sand-lime mixtures

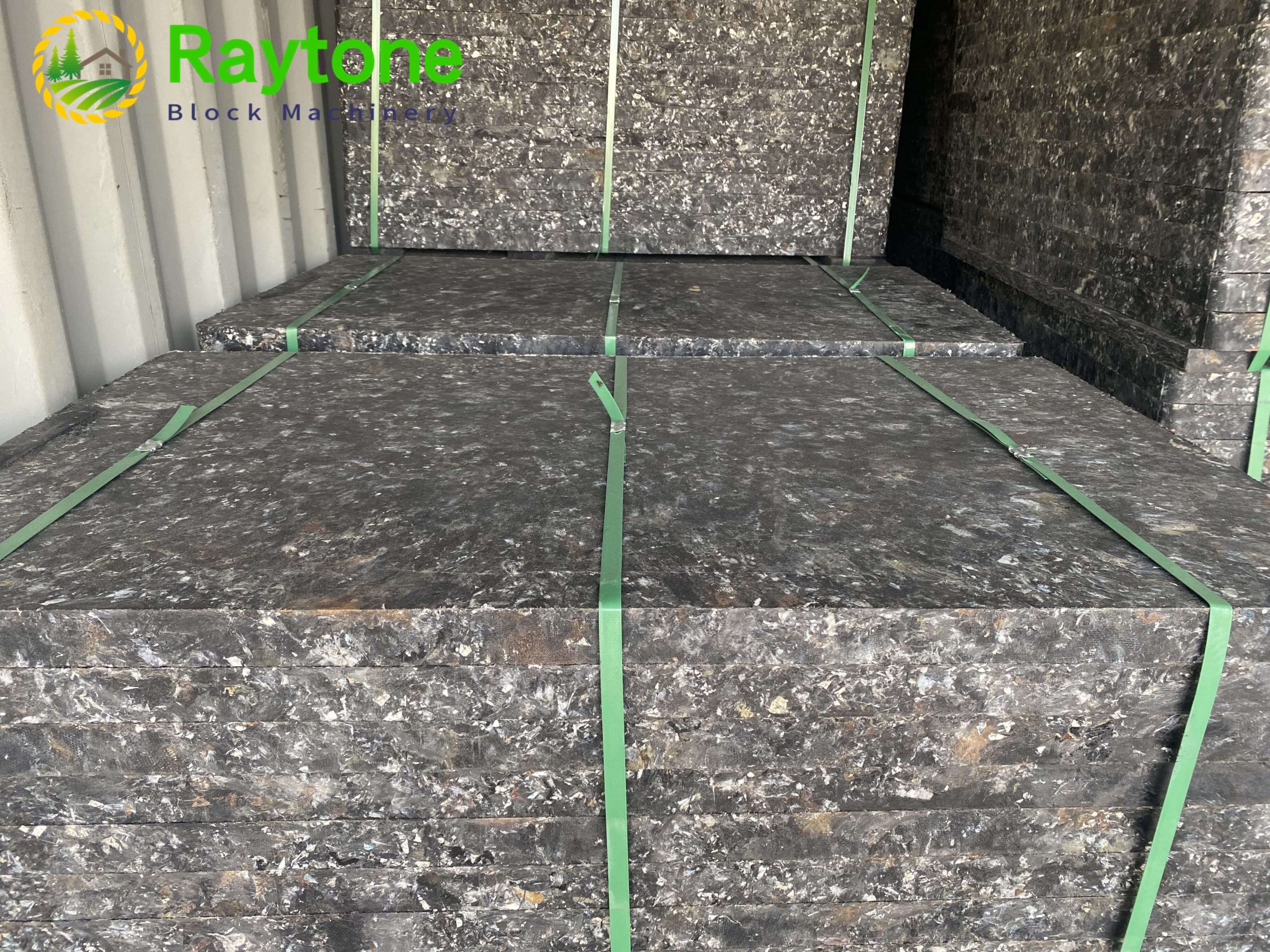

– Recycled materials

Material compatibility extends to the machine’s ability to handle different moisture contents and aggregate sizes. Look for features like adjustable mixing ratios and interchangeable molds to enhance versatility. Some advanced models offer programmable settings for different material compositions, ensuring optimal results across various brick types.

Automation Level and Control Systems

The level of automation in a small brick making machine significantly impacts operational efficiency and product consistency. While fully automated systems offer maximum productivity, semi-automatic options can provide a balance between control and output. Consider the following automation features:

– PLC (Programmable Logic Controller) systems for precise process control

– Touch-screen interfaces for easy operation and monitoring

– Automated material dosing and mixing

– Self-diagnostic capabilities for maintenance alerts

Advanced control systems allow for fine-tuning of parameters such as pressure, vibration frequency, and curing time. This level of control ensures consistent brick quality and allows for easy adaptation to different production requirements.

Assessing the Quality and Durability of Small Brick Making Machines

Construction Materials and Build Quality

The longevity and performance of a small brick making machine largely depend on its construction. High-quality machines typically feature:

– Robust steel frames resistant to vibration and wear

– Precision-engineered components for accurate molding

– Corrosion-resistant materials in critical areas

– High-grade hydraulic systems for reliable operation

Inspect the welding quality, surface finish, and overall craftsmanship. Well-built machines often have reinforced stress points and protected electrical components, enhancing durability in demanding environments.

Mold Design and Precision

The mold system is the heart of any brick making machine. Look for:

– Hardened steel or wear-resistant alloy molds

– Precision-machined surfaces for consistent brick dimensions

– Easy-to-change mold sets for production flexibility

– Effective compaction mechanisms for uniform density

Some advanced machines offer vibration-assisted molding, which improves brick density and strength. Consider the ease of mold maintenance and replacement, as these factors affect long-term operational costs.

Maintenance Requirements and Accessibility

Regular maintenance is crucial for the longevity of your small brick making machine. Evaluate the following aspects:

– Accessibility of key components for cleaning and repairs

– Availability of spare parts and their cost

– Lubrication systems and their efficiency

– Ease of adjusting and calibrating critical settings

Look for machines with modular designs that facilitate easy component replacement. Some manufacturers offer remote diagnostic capabilities, allowing for quick troubleshooting and reduced downtime.

Evaluating Manufacturer Reputation and After-Sales Support

Brand History and Market Presence

When investing in a small brick making machine, the reputation of the manufacturer plays a crucial role. Research the brand’s history, focusing on:

– Years of experience in brick machine manufacturing

– Market share and global presence

– Industry awards and recognitions

– Participation in trade shows and industry events

A well-established manufacturer is more likely to offer reliable products and long-term support. Look for companies that continuously invest in research and development, as they often lead in innovation and product improvement.

Customer Reviews and Case Studies

Gather insights from existing users of the small brick making machines you’re considering. Focus on:

– Customer testimonials and success stories

– Independent reviews on industry forums and platforms

– Case studies detailing real-world applications and results

– Feedback on machine performance, reliability, and support

Pay attention to comments about long-term performance, maintenance issues, and the manufacturer’s responsiveness to customer needs. This information can provide valuable insights into the machine’s real-world capabilities and the company’s commitment to customer satisfaction.

Warranty and After-Sales Service

A comprehensive warranty and reliable after-sales support are essential for minimizing downtime and protecting your investment. Consider the following:

– Duration and coverage of the warranty

– Availability of extended warranty options

– Response time for technical support and on-site assistance

– Training programs for operators and maintenance staff

– Availability of maintenance contracts and service packages

Look for manufacturers offering 24/7 technical support and those with service centers or partners near your location. Some companies provide remote monitoring and predictive maintenance services, which can significantly reduce unexpected breakdowns and optimize machine performance.

Conclusion

Choosing a quality small brick making machine requires careful consideration of various factors, including production capacity, material versatility, automation level, build quality, and manufacturer reputation. By thoroughly evaluating these aspects, you can select a machine that not only meets your current production needs but also supports your long-term business growth. Remember that the initial investment in a high-quality machine often translates to improved efficiency, reduced maintenance costs, and superior product quality in the long run. Take your time to research, compare options, and consult with industry experts to make an informed decision that will benefit your brick-making operations for years to come.

Contact Us

At Raytone Machinery, we understand the importance of selecting the right small brick making machine for your business. Our range of high-quality concrete block machines combines performance, reliability, and versatility to meet diverse production needs. With our commitment to cost-effective solutions and excellent customer value, we’re here to help you make the best choice for your brick-making operations. For more information about our products and how they can benefit your business, please contact us at hazel@raytonechina.com. Let us help you build a solid foundation for your success!

References

- Johnson, R. (2021). “Modern Brick Making Technologies: A Comprehensive Guide.” Construction Engineering Quarterly.

- Zhang, L. et al. (2020). “Advancements in Small-Scale Brick Production Machinery.” Journal of Construction Materials.

- Smith, A. (2022). “Evaluating Efficiency in Brick Manufacturing Equipment.” International Concrete Institute Review.

- Brown, M. (2019). “Sustainability in Brick Production: The Role of Advanced Machinery.” Green Building Technologies.

- Patel, S. (2023). “Quality Control in Automated Brick Production Systems.” Journal of Building Materials and Structures.

- Thompson, E. (2021). “Cost-Benefit Analysis of Investing in High-End Brick Making Machines.” Construction Economics Review.