If you’re in the market for a high-quality manual clay brick making machine, look no further than Raytone Machinery. As a leading global manufacturer of block machines, Raytone offers top-notch manual clay brick machines that combine performance, reliability, and versatility. Their extensive range of block-making solutions includes fully automatic, semi-automatic, and manual options, catering to various construction and building needs. Raytone’s commitment to cost-effective solutions ensures excellent value for customers worldwide. With a focus on durability and efficiency, Raytone’s manual clay brick machines are designed to meet the demands of modern construction projects while maintaining ease of use and consistent output quality.

Understanding Manual Clay Brick Making Machines

What is a Manual Clay Brick Making Machine?

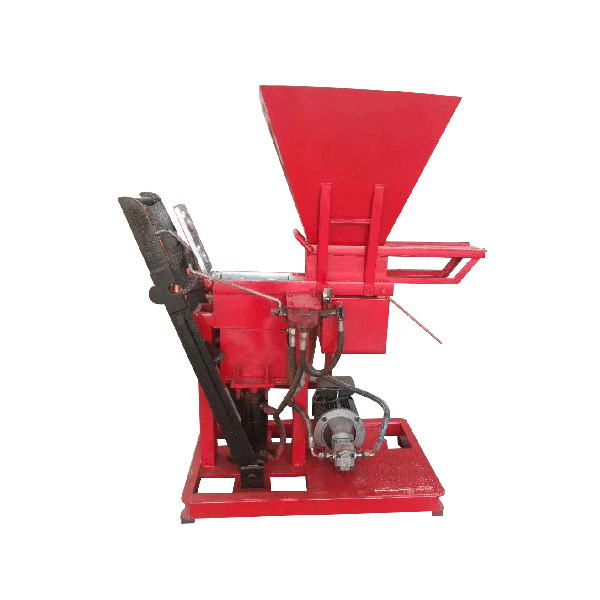

A manual clay brick making machine is a specialized piece of equipment designed to produce clay bricks without relying on complex automated systems. These machines are ideal for small to medium-scale brick production operations, offering a balance between traditional craftsmanship and modern efficiency. Unlike their automated counterparts, manual machines require more hands-on operation but provide greater control over the brick-making process.

Components of a Manual Clay Brick Machine

Manual clay brick making machines typically consist of several key components. The main frame provides structural support, while the mold box shapes the clay mixture into bricks. A pressure mechanism, often lever-operated, applies the necessary force to compress the clay. Additionally, these machines may include a mixing unit for preparing the clay mixture and a cutting mechanism for creating uniform brick sizes.

Benefits of Using Manual Brick Making Equipment

Opting for a manual clay brick making machine offers numerous advantages. These machines are generally more affordable than automated systems, making them accessible to smaller businesses or those just starting in brick production. They’re also easier to maintain and repair, reducing downtime and operational costs. Manual machines provide flexibility in production, allowing for quick adjustments to brick sizes or shapes. Moreover, they’re excellent for producing specialty or custom bricks that may not be feasible with large-scale automated production.

Factors to Consider When Buying a Manual Clay Brick Machine

Production Capacity and Efficiency

When selecting a manual clay brick making machine, it’s crucial to consider its production capacity. Evaluate your project requirements and choose a machine that can meet your output needs. While manual machines may not match the speed of fully automated systems, high-quality models can still offer impressive efficiency. Look for features that enhance productivity, such as quick-release mechanisms for easier brick removal or adjustable pressure settings for different clay consistencies.

Build Quality and Durability

The longevity of your manual clay brick machine depends largely on its build quality. Opt for machines constructed with robust materials like high-grade steel, which can withstand the rigors of daily use. Pay attention to the quality of moving parts, such as levers and hinges, as these are prone to wear over time. A well-built machine will not only last longer but also produce more consistent results throughout its lifespan.

Ease of Use and Maintenance

User-friendliness is a key factor in manual brick making equipment. Look for machines with ergonomic designs that reduce operator fatigue during extended use. Easy-to-clean molds and accessible components simplify maintenance tasks, ensuring your machine remains in top condition. Consider the availability of spare parts and after-sales support, as these can significantly impact your machine’s long-term usability and value.

Raytone’s Manual Clay Brick Making Machines: Features and Benefits

Advanced Design for Optimal Performance

Raytone’s manual clay brick making machines stand out with their innovative design features. The company’s engineering team has developed a unique pressure distribution system that ensures uniform compression across the entire brick surface. This results in bricks with consistent density and strength, crucial for high-quality construction projects. The machines also incorporate precision-crafted molds that produce bricks with sharp edges and smooth surfaces, enhancing the aesthetic appeal of the final product.

Versatility in Brick Production

One of the key advantages of Raytone’s manual clay brick machines is their versatility. These machines can handle various clay mixtures, allowing producers to create bricks with different properties to suit specific project requirements. The adjustable mold system enables quick changes in brick sizes and shapes, providing flexibility to meet diverse customer demands. This versatility makes Raytone’s machines an excellent choice for businesses looking to expand their product range without investing in multiple specialized machines.

Cost-Effective and Eco-Friendly Operation

Raytone has designed its manual clay brick making machines with a focus on cost-effectiveness and environmental sustainability. The machines are engineered for optimal energy efficiency, reducing operational costs and minimizing environmental impact. The manual operation eliminates the need for complex electrical systems, further lowering energy consumption. Additionally, Raytone’s machines are designed to minimize material waste during the brick-making process, contributing to more sustainable production practices and improved resource utilization.

Conclusion

When it comes to finding the best manual clay brick making machine, Raytone Machinery emerges as a top choice for quality, reliability, and value. Their range of manual brick machines offers the perfect blend of traditional craftsmanship and modern engineering, suitable for various production scales. By considering factors such as production capacity, build quality, and ease of use, you can make an informed decision that aligns with your specific needs. Raytone’s commitment to innovation, versatility, and cost-effectiveness positions them as a leading provider in the brick-making industry.

Contact Us

Experience the Raytone difference in manual clay brick production. Our machines are designed to deliver superior performance, durability, and value, helping you create high-quality bricks efficiently and cost-effectively. For more information about our manual clay brick making machines or to discuss your specific requirements, contact us at hazel@raytonechina.com. Let Raytone Machinery be your partner in building a stronger, more efficient brick production operation.

References

- Journal of Construction Materials: “Advancements in Manual Clay Brick Production Techniques”.

- International Conference on Sustainable Building Materials Proceedings.

- Handbook of Brick and Mortar Manufacturing, 5th Edition.

- Clay Brick Association Quarterly Report: “Market Trends in Manual Brick Production”.

- Engineering and Technology Magazine: “Innovation in Small-Scale Brick Making Equipment”.

- Global Construction Review: “The Resurgence of Artisanal Brick Production Methods”.