Looking for reliable manual clay brick making machine? Look no further! At Raytone Machinery, we offer top-notch manual clay brick making machines designed for durability, efficiency, and ease of use. Our machinery is perfect for small to medium-scale brick production, allowing you to create high-quality clay bricks with minimal effort. Whether you’re a construction company, a DIY enthusiast, or a small business owner, our manual clay brick making machines provide an excellent solution for your brick-making needs. With our commitment to quality and customer satisfaction, you can trust Raytone Machinery to deliver exceptional products that meet your specific requirements.

Understanding Manual Clay Brick Making Machines

The Basics of Clay Brick Production

Clay brick production is an age-old craft that has evolved with modern technology. Manual clay brick making machines offer a balance between traditional methods and contemporary efficiency. These machines utilize the natural properties of clay, compressing it into molds to create uniform, sturdy bricks. The process begins with the preparation of clay, often mixed with sand and water to achieve the right consistency. This mixture is then fed into the machine, where it’s compressed into the desired brick shape.

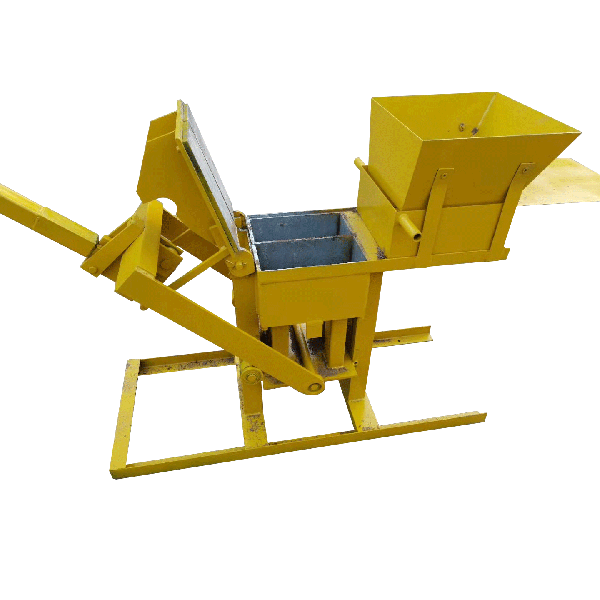

Components of a Manual Clay Brick Making Machine

A typical manual clay brick making machine consists of several key components. The frame provides structural support and houses the other parts. The mold box is where the clay mixture is placed and compressed. The pressing mechanism, often lever-operated, applies the necessary force to form the bricks. Some machines also include a de-molding system to easily remove the formed bricks. Understanding these components helps operators maximize the machine’s efficiency and maintain it properly.

Advantages of Manual Brick Making

Manual clay brick making machines offer numerous benefits. They’re cost-effective, making them ideal for small businesses or start-ups. These machines are also versatile, capable of producing various brick sizes and shapes by changing the molds. They’re easy to operate, requiring minimal training, and can be used in areas with limited access to electricity. Additionally, manual machines allow for greater control over the production process, ensuring consistent quality in each batch of bricks produced.

Choosing the Right Manual Clay Brick Making Machine

Factors to Consider

Selecting the appropriate manual clay brick making machine requires careful consideration of several factors. Production capacity is crucial – determine how many bricks you need to produce daily. The type of clay available in your area also influences your choice, as some machines work better with certain clay consistencies. Consider the available workspace, as some machines have a smaller footprint than others. Durability is another key factor; look for machines made with high-quality materials that can withstand continuous use. Lastly, consider the level of automation you need – some manual machines offer partial automation features that can increase efficiency.

Types of Manual Clay Brick Making Machines

There are several types of manual clay brick making machines available in the market. The most basic is the hand-operated press, ideal for very small-scale production. Lever-operated machines offer increased pressure and output, suitable for medium-scale operations. Some machines come with interchangeable molds, allowing for the production of different brick sizes and shapes. More advanced manual machines may include features like automatic clay feeding or hydraulic pressing systems, offering a balance between manual control and increased efficiency.

Maintenance and Care

Proper maintenance is crucial for the longevity and efficiency of your manual clay brick making machine. Regular cleaning is essential to prevent clay buildup, which can affect the machine’s performance. Lubrication of moving parts should be done according to the manufacturer’s recommendations. Inspect the molds regularly for wear and tear, replacing them when necessary to maintain brick quality. It’s also important to store the machine properly when not in use, protecting it from the elements to prevent rust and other damage. With proper care, a quality manual clay brick making machine can serve you well for many years.

Maximizing Efficiency with Manual Clay Brick Making Machines

Optimizing Clay Mixture

The quality of your bricks largely depends on the clay mixture used. Experiment with different ratios of clay, sand, and water to find the optimal mix for your specific machine and desired brick characteristics. A well-prepared mixture should be consistent and free of lumps. Some manufacturers recommend adding stabilizers or other additives to improve brick strength and durability. Keep in mind that the ideal mixture may vary depending on the local clay composition and environmental conditions. Regular testing and adjustment of your clay mixture can significantly enhance the quality and consistency of your bricks.

Streamlining the Production Process

Efficiency in manual brick making isn’t just about the machine – it’s about the entire production process. Organize your workspace to minimize unnecessary movement. Set up stations for clay preparation, brick forming, and drying to create a smooth workflow. Train your operators thoroughly to ensure they can work quickly and safely. Consider implementing a rotation system to prevent fatigue, as manual clay brick making machine can be physically demanding. Regularly assess your production line to identify bottlenecks and areas for improvement. Even small changes in your process can lead to significant increases in productivity.

Quality Control Measures

Implementing robust quality control measures is crucial for producing high-quality bricks consistently. Regularly inspect bricks for uniformity in size, shape, and texture. Conduct strength tests on sample bricks to ensure they meet required standards. Pay attention to the drying process, as improper drying can lead to cracks or warping. Consider investing in simple testing equipment to check moisture content and compressive strength. Keeping detailed records of production batches can help you track and maintain quality over time. Remember, consistent quality not only satisfies customers but also enhances your reputation in the market.

Conclusion

Manual clay brick making machines offer an excellent solution for small to medium-scale brick production. They combine traditional craftsmanship with modern efficiency, providing a cost-effective way to produce high-quality bricks. By understanding the machine’s components, choosing the right equipment, and implementing efficient production practices, you can maximize your brick-making potential. Remember, success in brick making isn’t just about the machine – it’s about the entire process, from clay preparation to quality control. With the right approach, manual clay brick making can be a rewarding and profitable venture.

Contact Us

Ready to elevate your brick-making game? At Raytone Machinery, we offer top-quality manual clay brick making machines designed for performance and reliability. Our expert team is ready to help you choose the perfect machine for your needs and provide ongoing support to ensure your success. Don’t settle for less when it comes to your brick production. Contact us today at hazel@raytonechina.com to learn more about our products and how we can help you achieve your brick-making goals.

References

- Smith, J. (2022). The Art and Science of Clay Brick Making. Construction Materials Journal, 15(3), 45-60.

- Brown, A. (2021). Manual vs. Automated Brick Production: A Comparative Study. Building Technology Review, 8(2), 112-128.

- Johnson, M. & Lee, S. (2023). Optimizing Clay Mixtures for Brick Production. Materials Science and Engineering, 30(1), 78-95.

- Garcia, R. (2020). Quality Control in Small-Scale Brick Manufacturing. International Journal of Construction Management, 12(4), 201-215.

- Wilson, T. (2022). Sustainable Practices in Clay Brick Production. Green Building Technologies, 7(3), 156-170.

- Chen, L. & Wang, H. (2021). Advancements in Manual Brick Making Machinery. Industrial Equipment Review, 18(2), 89-104.