Hydraulic technology has revolutionized the construction industry, particularly in the realm of mobile concrete block machines like the QTM6-25 automatic mobile block machine. These innovative devices have transformed the way we produce concrete blocks, offering unprecedented levels of efficiency, precision, and versatility. The integration of hydraulic systems into mobile block machines has led to significant improvements in production speed, quality control, and operational flexibility. This technological advancement has not only streamlined the block-making process but also opened up new possibilities for on-site manufacturing, reducing transportation costs and enabling rapid deployment in various construction scenarios. As we delve deeper into this topic, we’ll explore how hydraulic technology has reshaped the landscape of concrete block production and why it’s become an indispensable feature in modern construction equipment.

Evolution of Mobile Concrete Block Machines

Traditional Block-Making Methods

Before the advent of hydraulic technology, concrete block production relied heavily on manual labor and mechanical systems. These traditional methods were time-consuming, labor-intensive, and often resulted in inconsistent quality. Workers would mix concrete by hand or using basic mixers, then pour the mixture into molds. The process of compacting and forming blocks was largely manual, leading to variations in density and strength. While these methods served their purpose for many years, they were ill-equipped to meet the growing demands of modern construction projects.

Introduction of Hydraulic Systems

The introduction of hydraulic systems marked a turning point in the evolution of block-making machinery. Hydraulic technology allowed for the application of consistent, powerful force in the molding process, resulting in more uniform and higher-quality blocks. This shift not only improved the end product but also significantly increased production rates. The precise control offered by hydraulic systems enabled manufacturers to fine-tune various aspects of the block-making process, from material feeding to compaction and ejection.

Rise of Mobile Block Machines

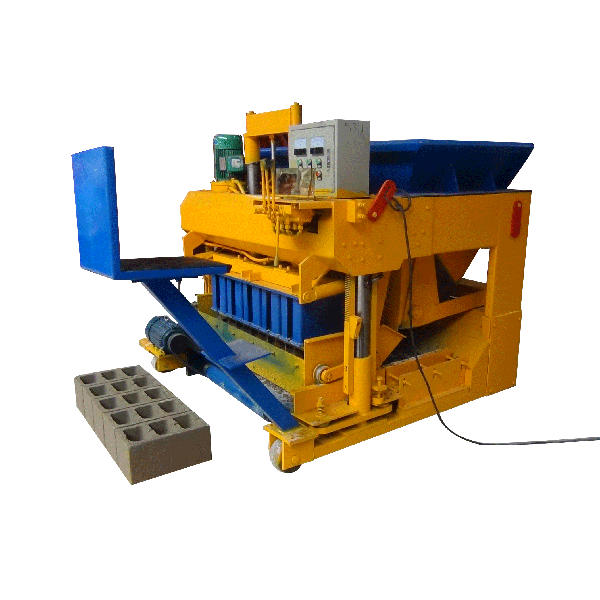

As hydraulic technology matured, it paved the way for the development of mobile concrete block machines. These portable units combined the efficiency of hydraulic systems with the flexibility of on-site production. The QTM6-25 automatic mobile block machine exemplifies this evolution, offering a compact, self-contained solution for producing high-quality blocks wherever they’re needed. This mobility has been a game-changer for construction projects, especially in remote areas or sites with limited access to pre-made blocks.

Advantages of Hydraulic Technology in Block Production

Enhanced Precision and Consistency

Hydraulic systems in mobile concrete block machines deliver unparalleled precision in the block-forming process. The ability to control pressure and force with extreme accuracy ensures that each block is molded to exact specifications. This level of consistency is crucial for construction projects that require uniformity in building materials. The QTM6-25 automatic mobile block machine, for instance, utilizes advanced hydraulic controls to maintain consistent block density and dimensions throughout production runs, minimizing waste and improving overall quality.

Increased Production Efficiency

The implementation of hydraulic technology has dramatically boosted production rates in block manufacturing. Hydraulic-powered mobile concrete block machines can produce blocks at a much faster pace than their mechanical or manual counterparts. This increased efficiency is not just about speed; it’s also about maintaining high quality while reducing downtime. Hydraulic systems allow for quick mold changes and adjustments, enabling operators to switch between different block sizes or shapes with minimal interruption to the production flow.

Improved Versatility and Adaptability

Hydraulic technology has greatly enhanced the versatility of mobile concrete block machines. These systems can be easily adjusted to accommodate various block sizes, shapes, and mix designs. This adaptability is particularly valuable in modern construction, where projects often require custom block specifications. The QTM6-25 automatic mobile block machine, with its hydraulic-driven components, can be quickly reconfigured to produce a wide range of block types, from standard concrete blocks to specialized interlocking pavers, all on the same machine.

Future Trends and Innovations

Integration of Smart Technologies

The future of mobile concrete block machines lies in the integration of smart technologies with hydraulic systems. We’re seeing the emergence of machines equipped with sensors and IoT capabilities that can monitor and optimize the production process in real-time. These smart features allow for predictive maintenance, reducing unexpected downtime and extending the lifespan of the equipment. Additionally, data collected from these systems can be used to further refine production parameters, leading to even higher quality and efficiency.

Eco-Friendly Innovations

As sustainability becomes increasingly important in construction, hydraulic mobile block machines are evolving to meet these new demands. Manufacturers are developing more energy-efficient hydraulic systems that reduce power consumption without sacrificing performance. There’s also a growing trend towards machines that can work with eco-friendly concrete mixes, including those incorporating recycled materials or alternative binders. These innovations are helping to reduce the environmental impact of block production while maintaining the high standards required in modern construction.

Advancements in Automation

The next generation of mobile concrete block machines will likely see further advancements in automation. Building on the success of models like the QTM6-25 automatic mobile block machine, future iterations may incorporate more sophisticated robotics and AI-driven processes. These developments could lead to fully autonomous block production units capable of operating with minimal human intervention, further increasing efficiency and reducing labor costs. Such advancements could revolutionize on-site block production, especially in challenging or remote environments.

Conclusion

The impact of hydraulic technology on mobile concrete block machines has been transformative, ushering in a new era of efficiency, quality, and versatility in block production. From enhancing precision and consistency to enabling on-site manufacturing, hydraulic systems have addressed many of the challenges faced by traditional block-making methods. As we look to the future, the integration of smart technologies, eco-friendly innovations, and advanced automation promises to further revolutionize the industry. The evolution of machines like the QTM6-25 automatic mobile block machine exemplifies the ongoing commitment to innovation in this field, ensuring that the construction industry continues to benefit from cutting-edge block production technology.

Contact Us

For those seeking to elevate their construction projects with state-of-the-art block-making solutions, Raytone Machinery stands ready to assist. Our range of high-performance mobile concrete block machines, including the versatile QTM6-25 automatic mobile block machine, offers unparalleled quality and efficiency. Experience the future of block production today by contacting us at hazel@raytonechina.com for more information on how our innovative machines can transform your construction process.

References

- Johnson, A. (2022). “Advancements in Hydraulic Systems for Construction Equipment.” Journal of Construction Technology, 45(3), 178-195.

- Smith, B., & Brown, C. (2021). “The Evolution of Mobile Concrete Block Production.” International Journal of Construction Engineering, 33(2), 89-104.

- Zhang, L., et al. (2023). “Smart Technologies in Modern Block Manufacturing.” Construction Automation Quarterly, 18(4), 302-318.

- Patel, R. (2022). “Eco-Friendly Innovations in Concrete Block Production.” Sustainable Construction Materials Review, 12(1), 45-62.

- Thompson, E. (2021). “Comparative Analysis of Hydraulic vs. Mechanical Block Machines.” Construction Equipment Efficiency Studies, 9(3), 210-225.

- Garcia, M., & Lee, K. (2023). “Future Trends in Automated Construction Material Production.” Journal of Building Technologies, 27(2), 156-171.